- Home

- Ricoh's Technology

- Gas and Odor Sensing

Gas and Odor Sensing

Background

Audio and visual information is regularly captured with cameras and microphones and digitized, but olfactory information is not. Until now, firms have been unable to develop technology to digitize olfactory information, and it is difficult to visualize changes in odors and replicate the human sense that something smells different.

Solution

Individuals and organizations may want to detect anomalies in the air at home or at a workplace to prevent loss and accidents. They may want to capture changes in aromas and use them for product development or inspection. Those in the medical field may want to study how physiological changes are related to body odor, breath, or excreta odor. Meeting these needs requires a technology that measures multiple kinds of gases and odors made up of compound gases. To make it easy to digitize odor and identify changes, Ricoh has developed a technology that measures compound gases in real time in a variety of workplace environments.

Prototype gas/odor measuring instrument

Prototype gas/odor measuring instrument

Technical highlights

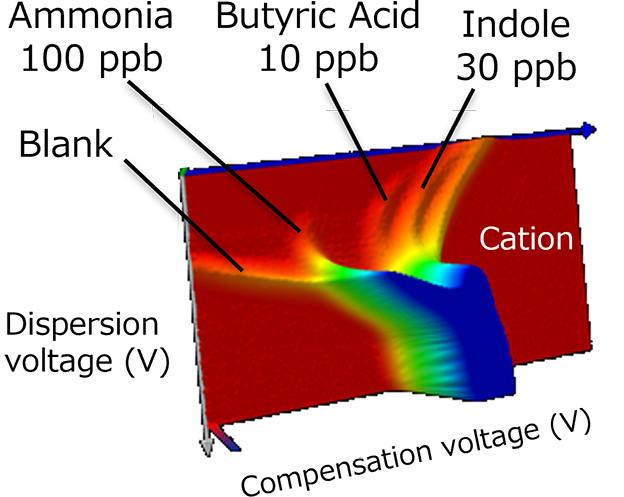

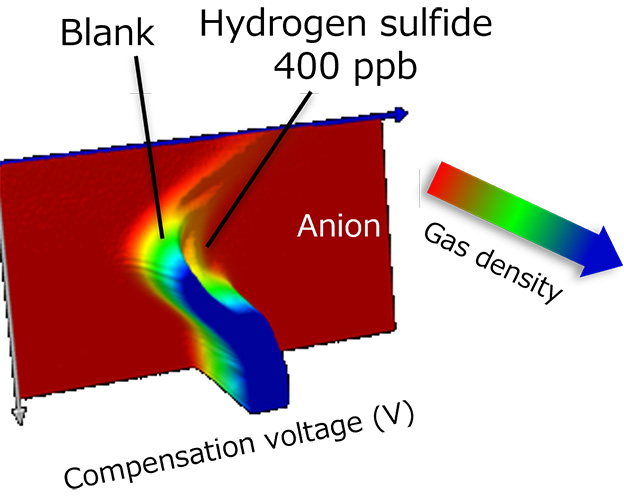

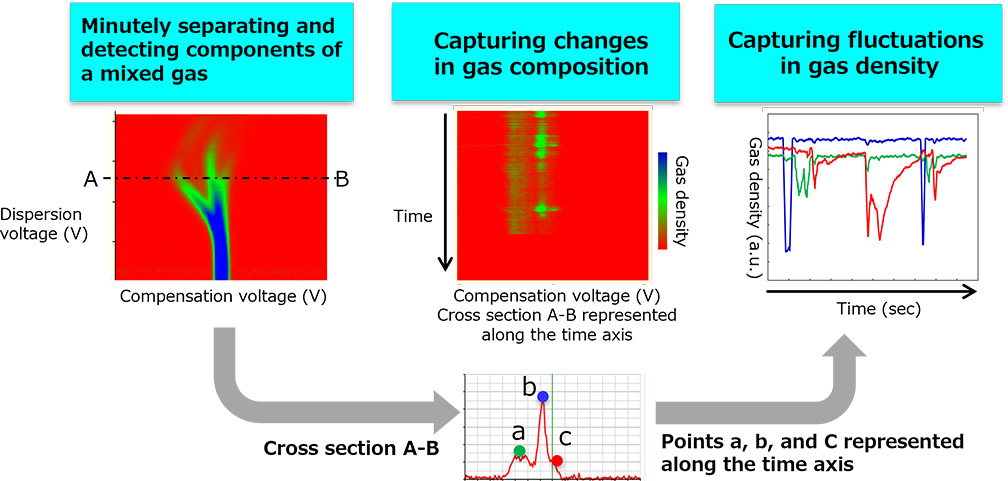

Ricoh has adopted FAIMS (Field Asymmetric Ion Mobility Spectrometry), a technology that classifies ionized gas and odor molecules in a special AC electric field into different types, and detects them as electric current. FAIMS was originally a technology for chemical analysis intended for use in a special environment; Ricoh re-developed the core part of FAIMS to make it usable in a generic environment. Ricoh's FAIMS system takes a sample of a compound gas using a pump and seamlessly measures it in real time to capture the changes in gas composition. The prototype is battery-driven and portable, measuring 220 mm wide, 120 mm high, and 160 mm deep.

The system is capable of:

- Identifying subtle differences in molecular structures between gas components,

- Detecting changes in the density of highly rarified components, whose molecule count is in the order of ppb (parts per billion) in the air, and

- Continuing real-time measurement of odor over a long period without adjusting to such odors like the olfactory sense of humans does.

Separating acidic and alkaline components from a compound gas and detecting them, which is difficult with conventional technology

(Quantifying components of excreta odor to visualize the intestinal environment)

Detection example

Seamlessly measuring the transitions in compound gas composition

(Enabling real-time logging, which is difficult with a conventional odor sensor)

Measurement example

Measurement example

Ricoh's vision

The cornerstones of this new technology are the ion control system and the drive circuit. The ion control system features MEMS (Micro Electro Mechanical Systems) technology developed by Ricoh through our long commitment to developing inkjet printheads. The drive circuit is based on the electrical technology developed for power supply circuits. Ricoh aims to build digital services that convert gases and odors into data in real time to meet the demands of many different workplaces. Ricoh will combine the new technology with 360-degree image and voice recognition technology to digitize the information perceived by all five senses, thus delivering unique value to homes and workplaces.

Sorted by : field “Analysis / Simulation”