- Home

- Ricoh's Technology

- Making Artificial Bones on a 3D Printer

Making Artificial Bones on a 3D Printer

Background

Artificial bones are often used in orthopedic surgery to treat bone defects.

Recently, 3D printers are garnering people's attention as they can precisely shape artificial bones which are very strong. Common 3D printing materials, however, cannot be used to make bones; artificial bones remain in the human body for life, therefore posing risks associated with long-term side effects caused by the likes of a metal allergy.

Solutions

To reproduce an individual's bone tissue structure, you need to design a three-dimensional structure that includes the inside of the bone. Based on the design, you need to implement precision 3D modeling.

Ricoh's new method can produce 3D shapes with a material that is both high in strength and osteo-inductivity. Ricoh's 3D printers will become indispensable tools in tailored medical services, enabling the production of artificial bones that match the varying bone shapes and sizes of individual patients.

Technical highlights

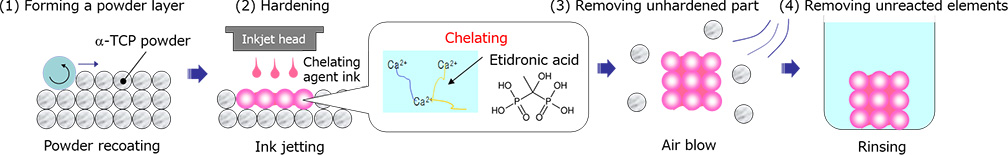

The new method fabricates artificial bone following the steps below. (Fig. 1)

First, the printer lays down a layer of alpha tri-calcium phosphate powder, which is bio-absorbable. The ink, which reacts with calcium and hardens by chelating reaction, is jetted from the inkjet head and then selectively dropped onto the powder layer. These two processes are repeated until the model data ends.

Fig. 1 3D printing process

Fig. 1 3D printing process

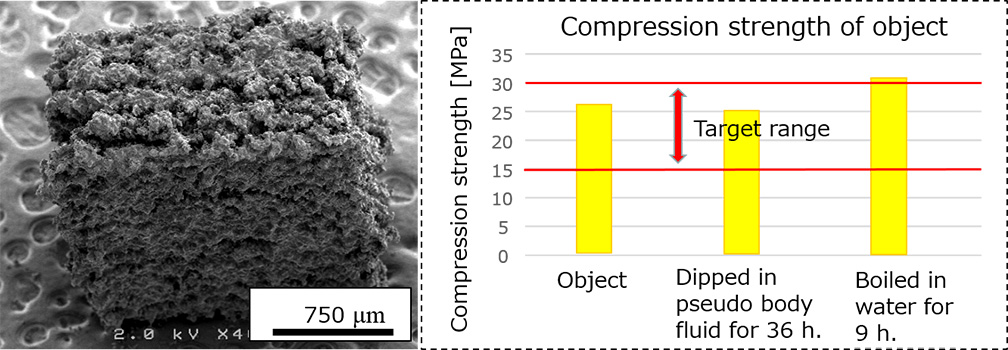

The ink hardens sufficiently in seconds after the application, allowing production of a strong, porous object. (Fig. 2)

Once the unhardened parts of the object have been removed and the resulting component rinsed in water for several minutes, cells can increase on it. No extra processes such as sintering are required; the new method will contribute to higher output (i.e. processing capability per unit time).

Fig. 2 Appearance and compression strengths of objects fabricated using the 3D printing process

Fig. 2 Appearance and compression strengths of objects fabricated using the 3D printing process

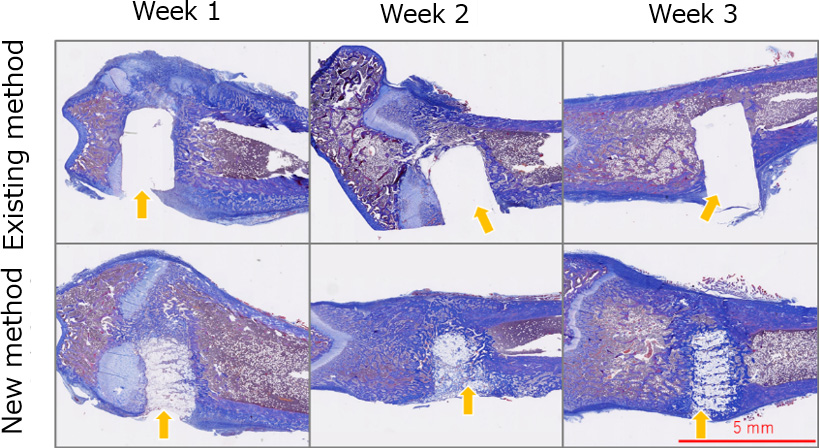

The bio-compatibility of the fabricated artificial bones was evaluated in terms of the following:

- Cell growth rate under culture environment, and

- Observation of tissue transplanted to rats through experiments.

As a result, we verified that the cells would increase well and natural bone tissue would quickly replace artificial bone. (Fig. 3)

The result indicates that the artificial bone is a good one; it does not hinder remodeling.

Fig. 3 New and existing methods as applied to femur bone of rats

Fig. 3 New and existing methods as applied to femur bone of rats

Ricoh's vision

Ricoh has nurtured inkjet systems and material technologies for more than 40 years. We are actively contributing to resolving social issues in healthcare and other areas.

- *

- Joint research partners: RIKEN and Nagoya University

Related information

- Development of new binder jetting process for fabricating bone regeneration implants / Society for Biomaterials' 2018 Annual meeting

- Vivo Study of Stable Alpha-TCP Scaffolds Fabricated by Modified Binder Jetting / Society for Biomaterials' 2018 Annual meeting

Sorted by : field “Inkjet”