- Home

- Ricoh's Technology

- Micro Granulation

Micro Granulation

Background

For maximum efficacy of pharmaceuticals, their active ingredients need to be delivered to the targeted parts of the body.

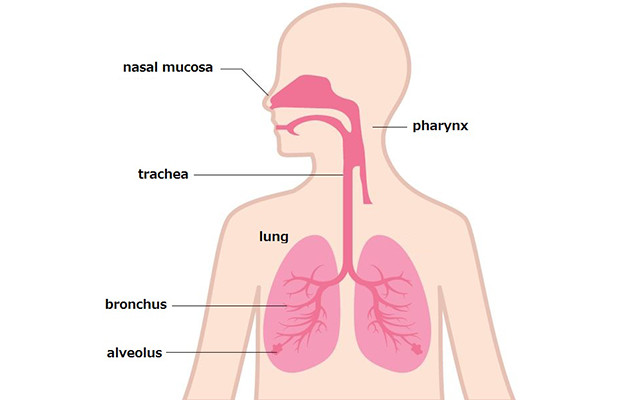

Dry powder inhalant needs to reach the bronchi and lungs to be efficacious.

Without the powder particles being uniform in size and composition, the inhalant cannot reach the targeted parts in effective quantities. Even worse, the inhalant residing in other parts of the body can pose risks of side effects.

Solutions

Creating particles of uniform size that easily reach the targeted partsTo efficiently deliver the inhalant to the targeted parts, you need to make its particle size suitable for the transport.

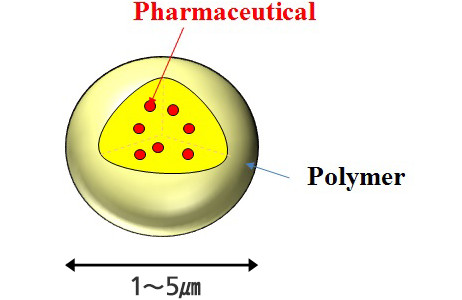

Alveoli, for instance, are located deep in the lungs where particles of 1 µm to 5 µm in diameter are effective. Ricoh has in precisely uniform size. been developing an inkjet micro granulator that is capable of creating microparticles The technology will help deliver the particles to the targeted parts for enhanced efficacy.

Technical highlights

The fine droplet drying (FDD) technology creates uniform particles in the order of microns. An inkjet head jets out very fine droplets at a high frequency, and the droplets are dried directly.

Ricoh's prototype jets out 520 million droplets per second, evenly creating a large quantity of fine powder.

Conventional micro granulation techniques, such as spray drying and pulverization, have difficulty producing micro particles of uniform size. Ricoh's FDD technology enables continuous, controlled jetting of droplets, thus producing micro particles of exceedingly uniform diameters.

Micro particles used for pharmaceuticals consist of effective agents and fillers (additives used for miscellaneous purposes such as shaping).

With FDD, an inkjet head jets out effective agents and fillers being evenly dispersed in a solvent. This feature ensures even composition of the effective agents and fillers, making the solubility constant and stabilizing absorbency of the effective agents.

Ricoh's vision

Ricoh will utilize its strengths nurtured through the development of printers, such as its ink-jet head technologies and materials technologies, to spawn innovation in pharmaceutical production through collaboration with Shizuoka Prefectural University and participation in the Pharma Valley Project at the Pharma Valley Center, of Shizuoka Industrial Foundation.

Sorted by : field “Inkjet”