- Home

- Ricoh's Technology

- 192-Ch High-Power Laser Marker

192-Ch High-Power Laser Marker

Printing consistent variable data, such as QR codes, at a maximum speed of 300m per min

Background

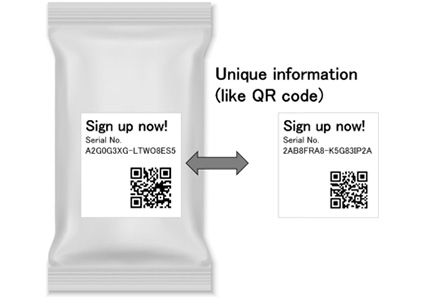

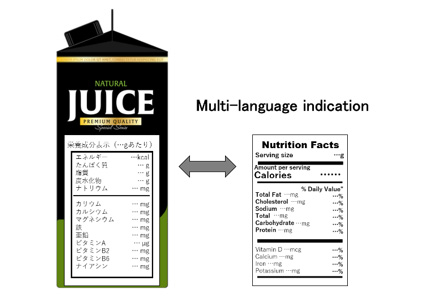

Product labels and packages have a wide variety of information printed on them. Some printed information is common to all products. Other information may vary by product, i.e., two-dimensional barcodes for product traceability management (such as QR codes), serial numbers, multilingual indications, etc.

In mass-production, high-volume fast printing is straightforward so long as the information is identical for all products. When unique information must be printed on each product, printing speeds tend to be too slow for high-volume runs. In those cases, costly alternatives to direct printing on products must be used, such as additional labels or stickers. Additionally, text legibility has always been an issue when using multiple languages, as the printed content must remain consistent. When many languages are packed together in small fonts, it makes them virtually illegible.

- *

- QR Code is a registered trademark of DENSO WAVE.

Solutions

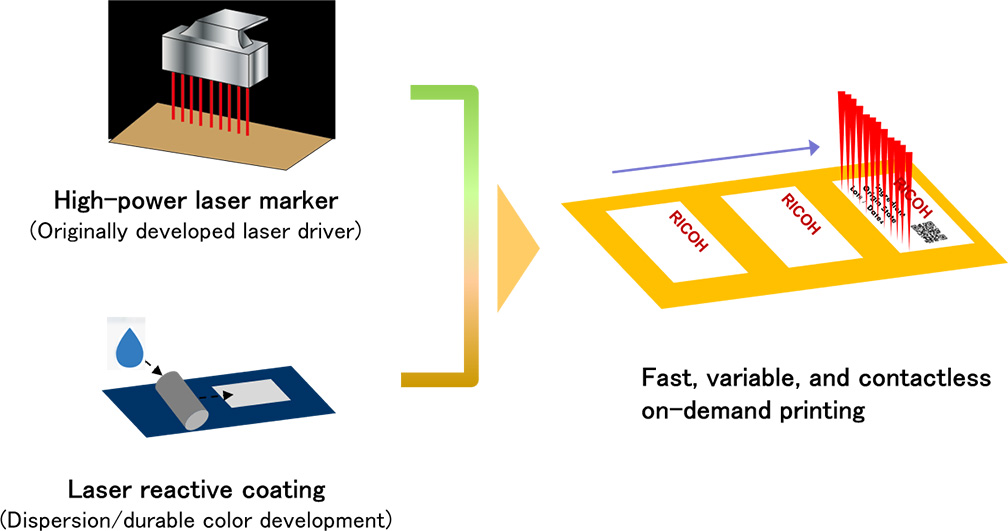

Ricoh has developed a laser marker capable of printing variable text and images at the world's fastest speeds*. It can independently print different images on a roll-to-roll film traveling at 300m/min, comparable to the rate of a mass-production line. The laser marker has the potential for use in a variety of production environments.

- *

- Per Ricoh research, as of August 19, 2020

- Limited-edition products produced in small quantities; messages presented only for a short period

- Individual QR codes and serial numbers for traceability or sales campaigns

- Different languages for various countries and regions

- Laser-based contactless printing; usable for printing on hygienic products

Inventory and traceability management support

Inventory and traceability management support

Information that varies for sales promotion

Information that varies for sales promotion

Multiple languages printed on a package

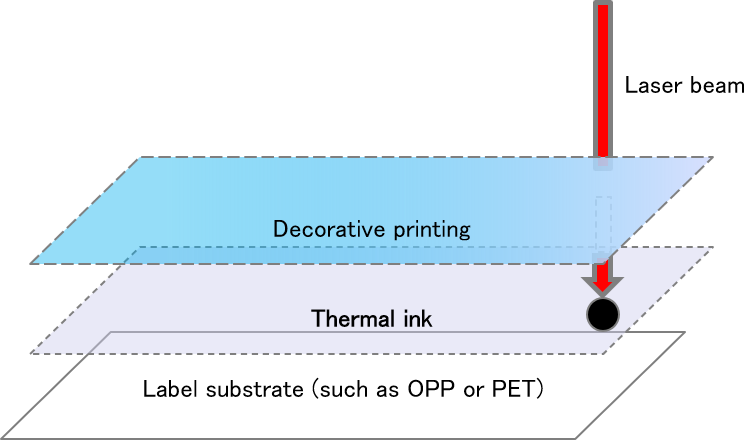

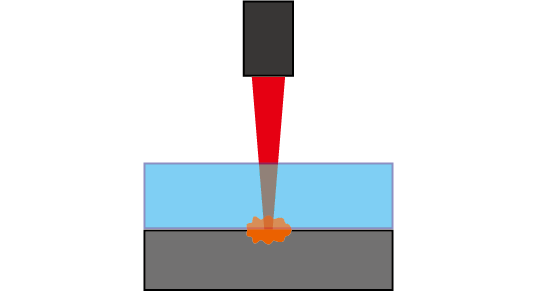

When used with Ricoh thermal media, it achieves ultra-high-speed printing of 200dpi at a maximum of 300m per min. The laser printing layer is nearly colorless and transparent, so information can be added while maintaining the product's packaging esthetic.

images appear in response to laser irradiation

(White text on a substrate is still under development)

Technical highlights

For fast printing, Ricoh has developed a high-power laser marker capable of instantly and independently driving the modulation of 192 laser light sources.

- World's most powerful 2000W laser marker*

High-speed thermal printing by inducing a thermal reaction in 1/100,000 second

* Checked by Ricoh, as of August 19, 2020 - independently modulated of 192 channels laser array at 80kHz

The Ricoh-developed laser driver modulates each channel up to 80,000 times per second, enabling fast, high-definition printing.

- Almost colorless and transparent thermal media layer

Ricoh has developed a thermal ink based on its dispersion technology and durable color development technology. Labels, flexible and rigid packaging, and many other items can be turned into a medium for laser printing by coating them with thermal ink.

Versatile usage of a 192-ch high-power laser device

Development is underway for a range of applications where high power, high speed, and high definition are beneficial.

- Laser marking on printing paper

The permanence of thermal ink has been an issue for some applications (such as medicine boxes). The laser marker burns the ink off, increasing print legibility over long periods.

Example of burn-off printing with laser

Example of burn-off printing with laser

(irradiating the laser to leave black portions) - Laser processing

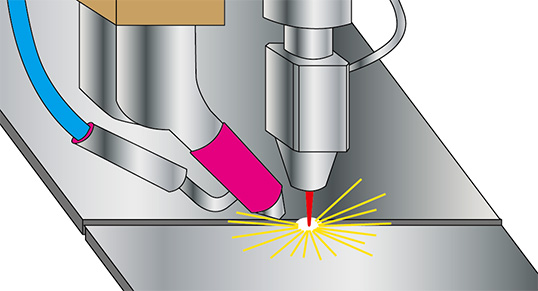

Without adhesives, resins can be welded by laser power with precise control.

High-speed modulation technology controls the beam shape and dot positions with precision, enhancing the quality of metal sheet welding and cutting and improves the quality of 3D printing.

Resin welding

Resin welding Metal welding

Metal welding

Ricoh's vision

Ricoh's thermal media enjoys an excellent reputation worldwide and is found in a variety of applications. Laser beam control technology has been nurtured through long years of R&D activities, including writing on multifunctional printers (MFPs). The novel laser system combines these proven technologies and enhances the speed and definition of thermal printing. These excellent features will be useful in many present and future applications where on-demand printing solutions are required.

Sorted by : field “Thermal Media” “Devices”