- Home

- Ricoh's Technology

- New Drying Technology That Improves Both Speed and Print Quality

New Drying Technology That Improves Both Speed and Print Quality

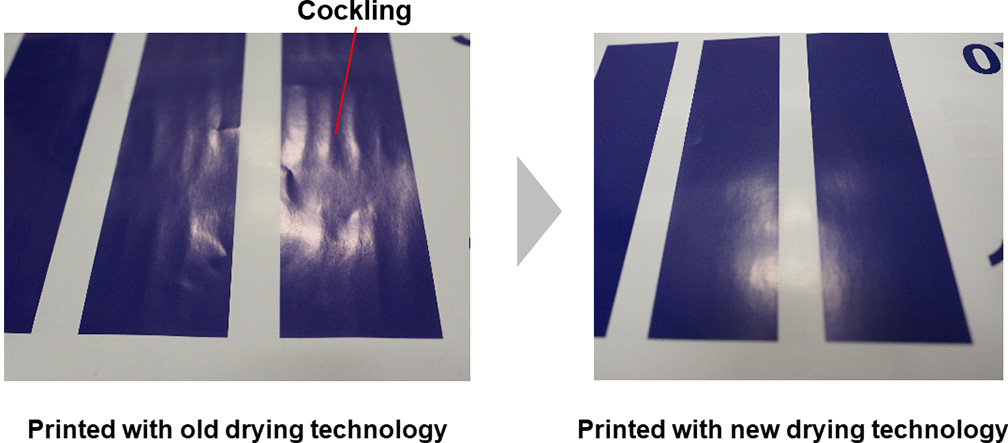

Ricoh has developed a new drying technology for the RICOH Pro VC70000 high-speed full-color inkjet continuous form printing system. Even when a dense image is printed or a thin sheet of paper is used, the technology prevents the paper from cockling. With its space-saving and power-saving design, the RICOH Pro VC70000 features greatly enhanced printing speeds and image quality.

Background

Conventional inkjet printers can cause paper to cockle; paper can stretch or shrink unevenly as it absorbs ink. Cockling often occurs when a dense image is printed or a thin sheet of paper is used and this is hard to avoid with conventional technologies.

Solutions

The newly developed drying system features Ricoh's proprietary drying technology. Even when a dense image is printed or a thin sheet of paper is used, the technology prevents the paper from cockling. The technology allows the printer to have a small footprint and save energy while greatly enhancing printing speeds and image quality.

Figure 1 Images printed with old and new drying technologies

Figure 1 Images printed with old and new drying technologies

Technical highlights

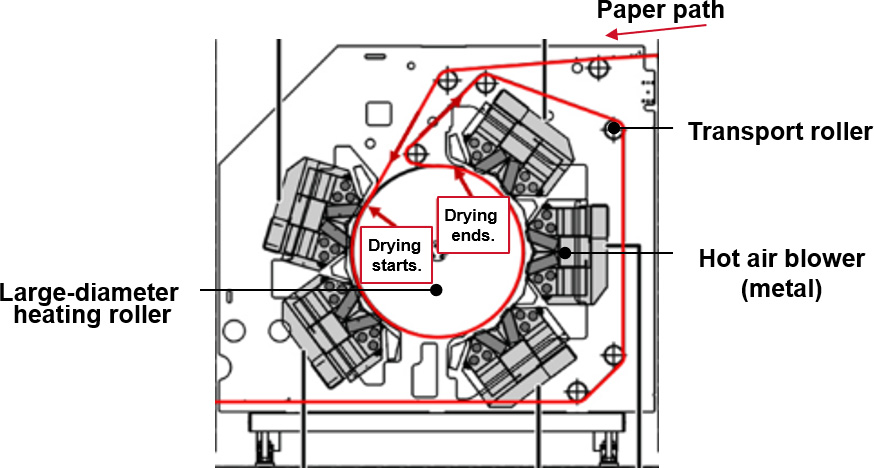

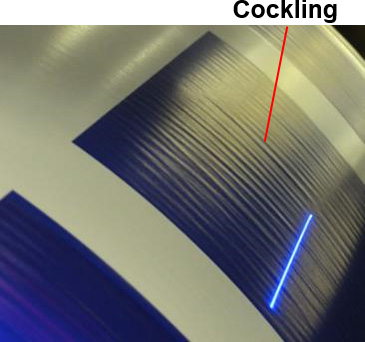

In a conventional drying system, paper passes around a large-diameter heating roller, which is surrounded with metal hot air blowers that are used to dry the ink (Figure 2). When a dense image or a thin sheet of paper is used, the sheet tends to stretch and shrink unevenly, resulting in a cockle (Figure 3).

Figure 2 Conventional drying system

Figure 2 Conventional drying system

Figure 3 Cockling on the surface of the large-diameter roller

Figure 3 Cockling on the surface of the large-diameter roller

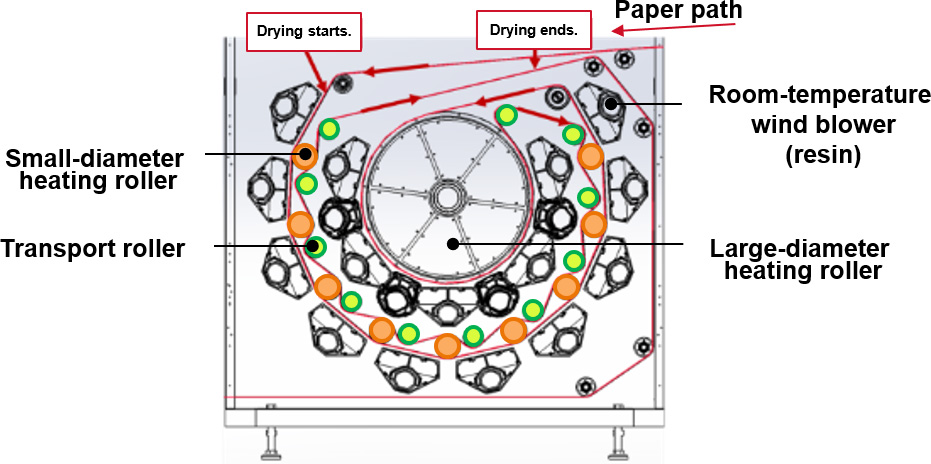

The new drying system has no hot air blowers. Instead, three components are installed: small-diameter heating rollers, transport rollers to ensure the paper tightly adheres to the small-diameter heating rollers, and resin blowers that pass room-temperature air over the ink (Figure 4).

Figure 4 New drying system

Figure 4 New drying system

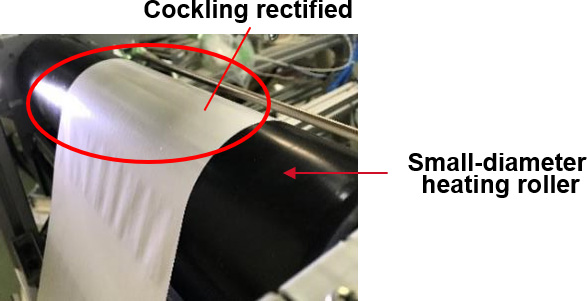

Figure 5 Cockling rectified by small-diameter heating roller

Figure 5 Cockling rectified by small-diameter heating roller

The new configuration has the following advantages:

- Cockling is rectified by the ironing effect; the small-diameter heating rollers iteratively heat the stretched paper sheet (Figure 5).

- A space-saving, long-path transport mechanism ensures high drying performance. The paper goes around inside the system, is wrapped around the small-diameter heating rollers twice and around the large heating roller once.

- Power consumption is low thanks to the room-temperature air blowers made of resin. The resin insulates heat and the air flow is controlled.

Even when a dense image is printed or a thin sheet of paper is used, the technology prevents the paper from cockling. In a space-saving and power-saving design, the RICOH Pro VC70000 features greatly enhanced printing speeds and image quality.

Ricoh's vision

The new ink and drying technologies developed for the RICOH Pro VC Series have been implemented on the RICOH Pro VC70000. With its release, Ricoh meets all the requirements of an inkjet printer in the commercial printing market: quality image, high productivity, and low cost. Ricoh is committed to delivering its inkjet technologies to a wide variety of high quality printing applications, including catalogs and magazines, where offset printing has been dominant. Ricoh's inkjet technology meets the requirements of the printing industry even in areas where higher-quality printing is demanded.

Video: Introducing RICOH Pro VC70000 [4:06]