- Home

- Ricoh's Technology

- Product Life-cycle Environmental Impact Assessment Technology

Product Life-cycle Environmental Impact Assessment Technology

Design that takes into account environmental impact makes it possible to reduce environmental impact

The Ricoh Group established the concept of "Comet Circle" in 1994 to achieve a sustainable society. We are working to reduce environmental impact over the product life cycle beyond the sphere of the Ricoh Group as a manufacturer and multiple sales companies. The product manufacturer has the greatest influence on the environmental impact over the product life cycle because it grasps the basic design of the product. To reduce environmental impact, the product designer, at an early stage, must take into account environmental impact over the life cycle. For that to be possible, a high-precision environmental impact assessment tool is indispensable, one that each designer can use simply and quickly.

In general, product environmental impact assessment requires special skills to handle, analyze and assess huge data over the product’s life cycle. Beyond that, because the assessor needs to be well versed in both business processes and environmental assessment, the number of specialists who can manage this is limited. All require a huge amount of time. Imaging equipment like printers and multifunction models comprise hundreds to thousands of parts, involving a huge number of material/parts suppliers. For that reason, to grasp the environmental impact across the entire product life cycle, we must assess throughout a vast supply chain.

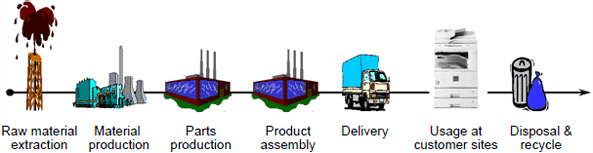

Figure 1: Product Life cycle

As environmental impact assessment technology takes into account the life cycle, LCA is becoming popular among manufacturers, including the Ricoh Group. LCA assesses environmental impact, such as resource consumption and greenhouse gas emission quantitatively and objectively. It covers all steps from raw materials extraction, production, transportation, and use to disposal of the target product.

Allow anyone to grasp environmental impact simply and quickly

Ricoh has developed an assessment system to reduce environmental impact by penetrating LCA in the design process, allowing anyone, simply, and in a short time to grasp environmental impact.

This assessment system separates information obtainable and operable at the design section from information prerequisite to assessment calculation and to maintain the system. The system comprises two subsystems, one of which allows assessment execution with only the former information; the other subsystem is used for the latter. With this configuration, the subsystem for a designer can be used merely with the input of a product’s parts list, which is used daily, and the product specification sheet, which includes product weight and part numbers for periodical maintenance. It completely eliminates information and functions not directly related to the designer, making possible the basis of the assessment system that features anyone, simply, and quickly.

Assessment subsystem for designers

The subsystem for designers has two modes: (1) assessment mode to execute assessment only of the designed products, and (2) simulation mode to evaluate a product under conditions after design change simulations.

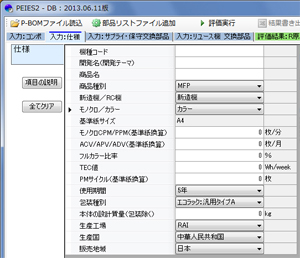

Figure 2: A screen in assessment mode

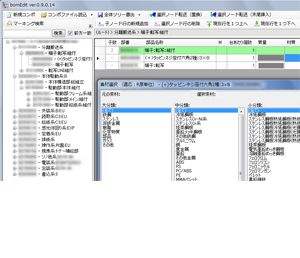

Figure 3: A screen in simulation mode

Assessment mode

The assessment mode focuses on the minimum steps and time required. Less than ten minutes of input work yields the environmental impact of all processes from material procurement to the disposal and recycling of the product; this includes resources consumed of all modules and parts comprising a product. In the past, the design section asked multiple specialists who were well acquainted with LCA. It took several weeks.

Figure 4: Example of assessment result by life cycle stage

Figure 5: Example of assessment result by exhaustible resources

Simulation mode

The simulation mode has a powerful edit function that features a high degree of freedom with minimum operation; it can implement simulation of an environmental impact, changing the terms and conditions of the design.

A typical case of the design improvement using the simulation mode

Typical issues with design improvement are to reduce product weight, the use of scarce resources, and to suppress environmental impact by reducing consumables that are used in high numbers.

In many cases, reduced product weight is proportional to reduced environmental impact. This does not necessarily apply, however, where there are parts and modules that contain many scarce resources. Scarce resources impart a heavy environmental impact, even if the total volume is small. Electronic elements comprising rare metals are typical. As shown in Figure 6, by substituting them with alternative material for electronic circuit boards without exploiting scarce resources, the environmental impact for substrate B will be smaller than A, even if substrate B is substantially heavier.

Figure 6: Environmental impact image with and without the use of rare metal

As shown in Figures 7 and 8, electrical-related modules (shown in yellow) with a small weight ratio occupy a high proportion with respect to environmental impact. In simulating reduced environmental impact at the early stages of design, it becomes important to consider which parts and modules need focus. In doing so, the weight of every part and module, the amount of scarce resources and environmental impact of all are scrutinized. This example shows that a review to substitute electrical-related elements and parts high in environmental impact is effective in lowering total environmental impact.

Figure 7: Constituent weight by module

Figure 8: Greenhouse effect gas emission amount associated with the constituent material by module

The influence on environmental impact differs greatly between parts low in exchange frequency and consumable parts exchanged frequently, considering the overall life cycle of a product. Using materials low in environmental impact for consumable parts, of which consumption is high, can suppress environmental impact across the life cycle shown in Figure 9.

Figure 9: Image of influence on environmental impact of a consumable part

This assessment system allows simulation while analyzing changes in subject and viewpoint, from one product to one element part. Conversely, it can be used to re-examine trends of the whole product, accumulating detailed simulation results. It is effective in drawing up a design guideline at an early stage, confirming assessment results, such as changes in weight or material of parts or modules, or to replace modules, against the component configuration.

Assessment results are effectively used also for disclosure of environmental information

The environmental impact resulting from this assessment system is harnessed also in prompt disclosure of environmental information. For instance, the data of this system is used also in obtaining EPEAT authentication. This intelligence infrastructure is also harnessed as environmental data of the product for disclosure to customers.

EPEAT was established for market development and sales promotion of ecologically friendly products. It is adopted as requisite for procurement by the United States federal government. It became applicable to PCs and display products in 2006 and imaging products in 2013. Examination is made on 33 items of indispensable standard and 26 items of arbitrary standard. Those focus on resource saving, energy saving, reduction and proscription of toxic substances, etc. Depending on the ratio of meeting the standard, an assessment of Gold, Silver or Bronze is registered.

Contributing to reduced environmental impact by establishing and promoting activities of the LCA system in the design process of the Ricoh Group including this environmental impact assessment technology has been evaluated highly. This, together with other groups’ environmental technologies and activities, resulted in award of the Industrial Science and Technology Policy and Environment Bureau chief prize of Ministry of Economy, Trade and Industry, top prize at the 7th LCA Japan Forum Commendation in 2010. The Ricoh Group continues its contribution in reducing environmental impact in technological development.

Sorted by : field “Resource Conservation” “Analysis / Simulation” | product type “Printing” “Environment”