- Home

- Occupational Health and Safety

Occupational Health and Safety

Policy and Basic Concept

Policy and Basic Concept

Throughout the first decade of the new millennium, Ricoh promoted the development of work environments that prioritize the health and safety of employees. From 2011 onwards, efforts have been made under the slogan of “One Ricoh“ to realize the lateral deployment of healthy and safe work environments among our affiliated companies in Japan (hereafter, “Ricoh Group in Japan“) where the realization of such workplaces had not yet been adequately promoted. These efforts are being headed by a special department that was established to build the industrial health system and manage safety and employee health for the entire Ricoh Group.

Basic Health and Safety Policy

The basic policy is to promote business activities that prioritize employee health and safety, based on the recognition by the management and all employees (Ricoh Group employees, employees of contractors, employees of temporary staffing companies, suppliers, construction workers, visitors, and all other persons involved in our business activities) that the development of business activities is based on the health and safety of employees.

Management shall set forth and express the direction and principles of health and safety upon agreement with employee representatives. The Ricoh Group Health and Safety Basic Policy and Action Guidelines are as follows.

Basic Health and Safety Policy

We strongly recognize the importance of ensuring the health and safety of our employees and creating a healthy and safe working environment through the implementation of our Management Philosophy, and we will achieve this goal through the efforts of the entire Ricoh Group.

Action Guidelines

- We will comply with domestic and international laws and regulations related to health and safety, set voluntary goals, and strive to achieve them.

- Continuously maintain and improve our voluntary health and safety promotion system in the process of ensuring the health and safety of our employees in order to create a comfortable work environment.

- Raise employee awareness and knowledge through health and safety education in order to enlighten and support employees taking interest in their health and health activities in society at large and act on their own initiative.

- Contribute to society at large by maintaining close relationships with society, proactively disclosing information, and subsidizing and supporting safety and health activities.

(Reference from Article 3 of the Ricoh Group Health and Safety Management Standard, Ricoh Group Standard)

Promotion Structure/ Basic Concept

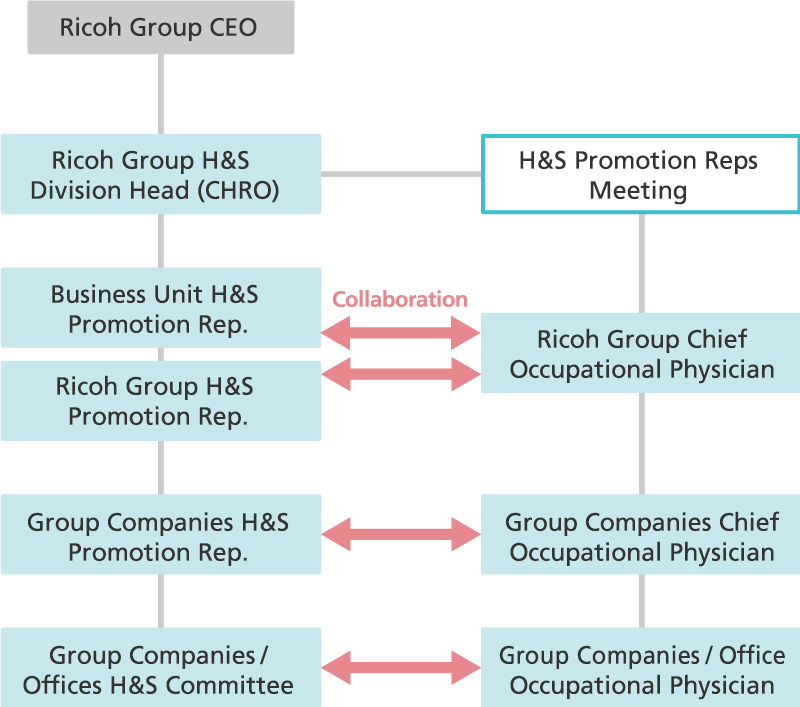

1) Ricoh Group H&S Promotion System

The Ricoh Group holds an annual Health and Safety Promotion Managers' Meeting that is attended by the health and safety promotion managers from all Group business units (BU)* and companies and is supervised by the division head in charge (CHRO), who oversee the health and safety activities of the entire Ricoh Group. This annual meeting determines the health and safety policy for the entire Group and confirms the progress of promotion measures. In addition, internal audits of the activity plans and status of activities at each site and group company are conducted on a regular basis, and efforts are made to make improvements and horizontally deploy them within the group.

*From FY2021, each BU newly established a health and safety promotion department in response to changes in the business environment.

All locations with more than 50 employees are required to establish a Health and Safety Committee. For locations with fewer than 50 employees, the safety committees will be replaced by workplace discussion meetings or liaison meetings led by Health and Safety Promotion Managers. All employees of the domestic group are affiliated with one of these organizations and are 100% engaged in health and safety activities, including health management. (As of FY2024, domestic group employees: 29,929 / 100% participation).

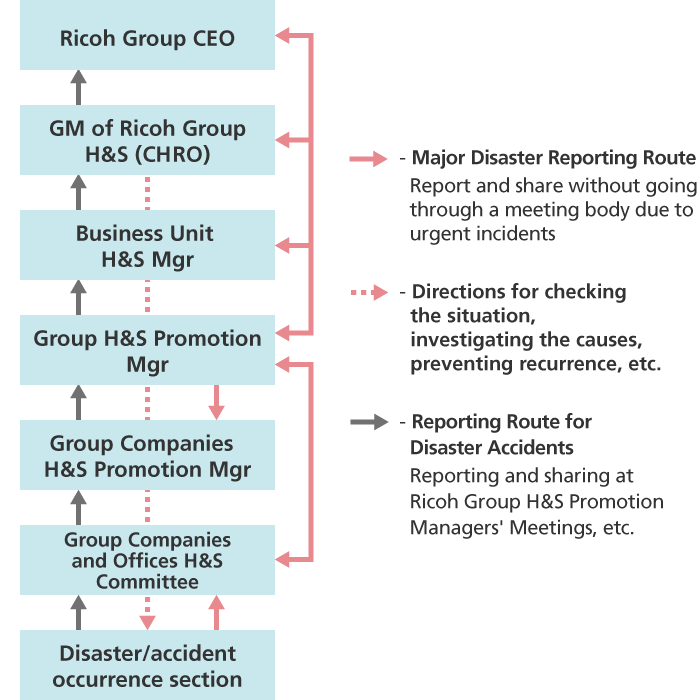

Process chart for reporting occupational accidents/incidents, confirming the situation, investigating the causes, and preventing recurrence

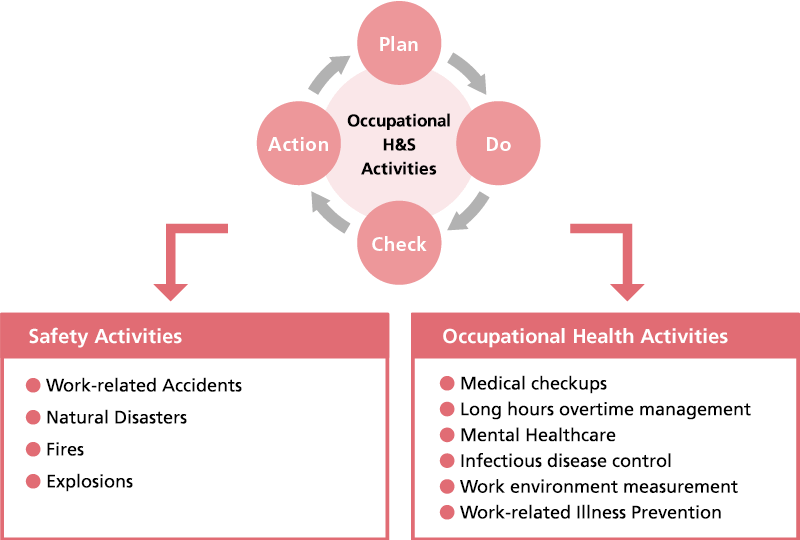

2) Concept of Occupational Health and Safety Activities

The Ricoh Group recognizes that encouraging self-initiated health and safety activities is a fundamental requisite for continuous improvement and spiraling up of activities. To this end, we are working to create a system to visualize the process of activities and have them lead to results.

Occupational Health and Safety Risk Assessment

The Ricoh Group conducts risk assessments to comprehensively ensure the safety of operations and equipment, as well as to prevent health hazards related to cancer risks. The methodology for risk assessments is defined in the Domestic Group Occupational Health and Safety Management Standards. It is implemented by 100% of the applicable domestic group companies (as of FY2024: 24 companies / 100% implementation).

The group has adopted "CREATE-SIMPLE" as a chemical substance assessment tool to promote autonomous chemical substance management. This tool has been rolled out to 100% of domestic group facilities handling chemical substances.

3) Occupational health and safety education

The Ricoh Group provides occupational health and safety education common to all Ricoh Group companies to foster safety awareness and healthcare literacy (awareness of self-health) at the time of joining the company. Since fiscal 2020, we have also introduced online training sessions to expand the scope of education.

In addition to the initial training upon joining the company, tailored education on occupational health and safety is carried out at each site according to job roles.

In fiscal 2024, the number of participants in Occupational Health and Safety Training was as follows:

General training: 58,939 people

Safety education: 61,482 people

Aim of occupational health and safety education

- Learning the basics of safety management to prevent employees from encountering work-related accident

- Understand the importance of taking care of one's own health

Safety Activities

Initiatives to Strengthen Safety Management

Since the beginning of 2000, the Ricoh Group has been promoting the certification and renewal of OSHMS certification by the Japan Industrial Safety and Health Association (JISHA), mainly at production sites.

Since 2011, we have established an internal certification system focused on verifying on-site implementation, based on the 'Guidelines on Occupational Safety and Health Management Systems (OSHMS Guidelines).' In 2024, we further revised our evaluation system to emphasize process-based assessments, enabling autonomous and continuous implementation of the PDCA cycle for safety and health activities. This enhanced framework is being horizontally deployed, primarily across our domestic production-related companies.

In addition, sales, service, and office affiliates are building a safety framework through the development of 5S activities, and research and development affiliates are implementing safety activities tailored to their actual situations, such as identifying and improving hazardous areas through risk assessments and strengthening safety education.

Furthermore, the Group has established Group-wide rules and measures to minimize damage in the event of a disaster requiring urgent action.

*Guidelines of the Ministry of Health, Labour and Welfare in alignment with the ILO guidelines.

Development and operation of the Ricoh Group's original occupational health and safety management system

The Ricoh Group has been implementing its own occupational health and safety management system since fiscal 2011 and is working to improve the level of health and safety throughout the Group by communicating best practices to all Group companies.

Building on our experience during the COVID-19 pandemic, we have adopted a hybrid evaluation approach that combines on-site assessments by evaluators with remote participation by experts with specialized knowledge. We also provide training to personnel responsible for promoting occupational safety and health at each group company. These trained evaluators conduct cross-company assessments, which help deepen learning through shared insights and best practices, while also contributing to the development of their competencies.

Conducting Group-wide risk assessment and education

Since fiscal 2018, the Ricoh Group has been conducting group-wide risk assessments, mainly in production and R&D, to continuously reduce risks (accident prevention) by identifying and improving hazardous areas including emergencies* . In parallel with this, we have established risk assessment training tools common to the Ricoh Group, and are working to improve accident prevention activities by updating the tools and training instructors corresponding to changes in the environment.

*Fire, explosion, electric shock, contact with hazardous materials, etc.

At production sites, we have established an " experiential " education system to prevent occupational accidents from occurring in the first place. This is based on the idea that "to improve safety sensitivity, it is important to experience hazards through the five senses, not only through classroom education." All employees receive safety education using a simulator that can reproduce hazards unique to the workplace, such as " entanglement," " trapped," and "solvent explosions."

Sharing information through a health and safety web portal site

Since 2021, we established a portal site for health and safety common to all Ricoh Group companies in Japan to provide an opportunity to share information on health and safety activities across the Ricoh Group. All information on occupational accidents are recorded on the portal site, and we are working to prevent the occurrence of similar accidents by sharing information on the causes and countermeasures of accidents that have occurred.

We also provide the results of risk assessments and internal calibration of the occupational health and safety management system to visualize information on the Ricoh Group's health and safety activities.

Results of Safety Activities in FY2024

In fiscal year 2024, as a result of measures we introduced to reduce workplace accidents, the "major accidents*" count remained atzero, the frequency rate of accidents leading to work absence is 0.39 this year, and the frequency rate of accidents not leading towork absence is 1.30 inthis year.

Occupational Accident Frequency Ratio

Source: Ministry of Health, Labour and Welfare, Survey of Occupational Accident Trends (survey of business establishments (with 100 or more employees) and survey of general construction industry)

Occupational Health Activities

Health Management Initiatives

Ricoh Group Health Declaration

Ricoh Group Health Declaration

The health of each employee in the Ricoh Group is the foundation for their own well-being and the foundation for the development of the Ricoh Group.

The Ricoh Group supports each employee’s "Proactive maintenance and promotion of health" and realizes a safe and comfortable work environment so that they can continue working with peace of mind.

※The Ricoh Group aims to create a work environment where people with illness can balance their treatment and work, as well as to realize a diversity conscious work environment where people can work with peace of mind.

April 2023

Ricoh Group CEO

Akira Oyama

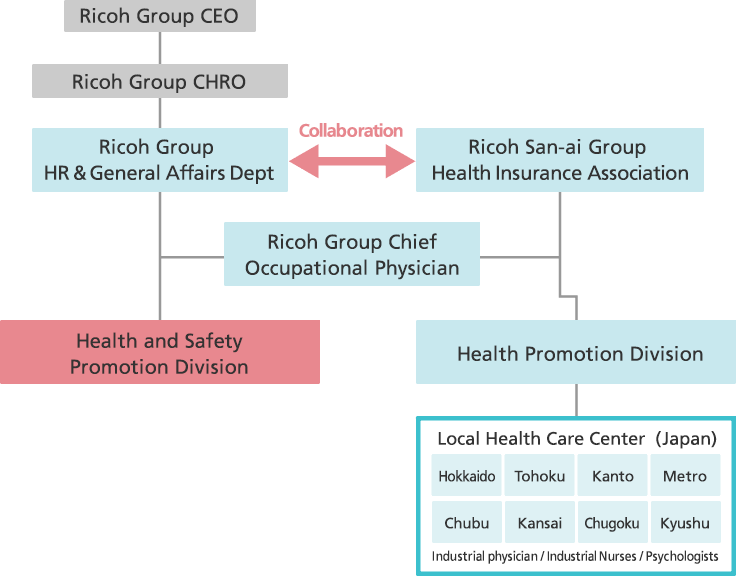

Ricoh Group Health Support Activity Management and Promotion System

The Ricoh Group implements health support activities for its employees through collaboration with the Ricoh San-ai Group Health Insurance Association.

Relationship between the health insurance association and the Ricoh Group's health support system

Ricoh Group Health Support Activity Structure

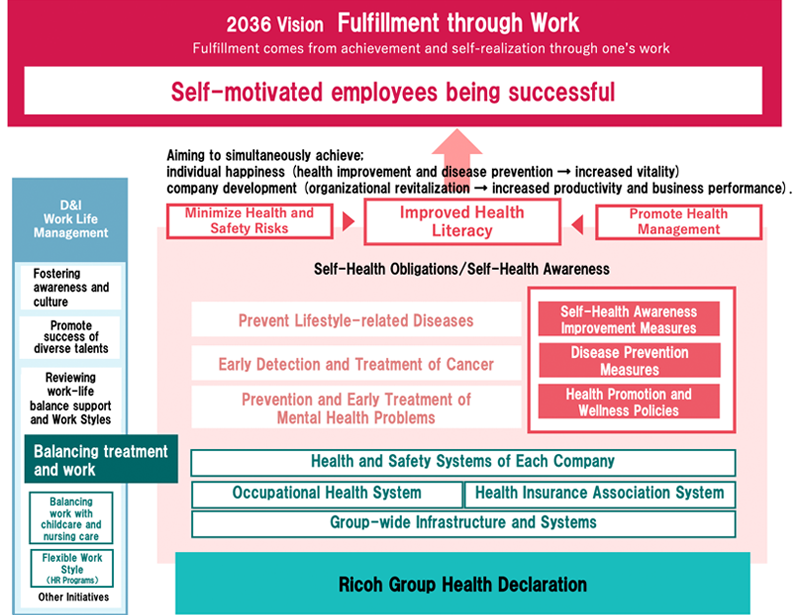

In anticipation of the Ricoh Group's vision for 2036, we have formulated a mid-term management plan based on the Ricoh Group Health Declaration and are promoting health support activities. Based on the mindset by employees to "take care of their own health," we aim to build a foundation for employees of the Ricoh Group to work vigorously and independently by enhancing their health literacy, which will simultaneously realize individual well-being and corporate development. To this end, we position "health" as a management issue and implement health management with a top-down management approach. Furthermore, to minimize safety and health risks, we are promoting activities mainly for the prevention of various lifestyle-related diseases, early detection and early treatment of cancer, and prevention and early treatment of mental health problems under the Ricoh Group Health Support Activity Structure.

Status of Health Promotion Activities and Targets

| FY2021 | FY2022 | FY2023 | FY2024 | Future Target | |

|---|---|---|---|---|---|

| Ratio of employees receiving periodic health checkups | 100% | 100% | 100% | 100% | Maintain 100% |

| Stress Check Inspection Rate | 93.7% | 95.0% | 95.0% | 94.6% | Improve from previous FY |

| Ratio of Employees with high stress | 7.0% | 7.0% | 7.0% | 6.3% | Reduce ratio of employees with high stress |

| Work Engagement | 2.52 | 2.54 | 2.54 | 2.57 | Improve from previous FY |

| Presenteeism: Level of company vitality calculated using third party methodology. | A | A | A | A | Improve from previous FY |

| Absenteeism: Rate of absence from work for more than one month | 1.5% (0.4%) |

1.3% (0.5%) |

1.4% (0.4%) |

1.34% (0.54%) |

Reduce from previous FY |

| Health checkup results (Based on employees over 40 years old) |

FY2021 | FY2022 | FY2023 | FY2024 | Future Target |

|---|---|---|---|---|---|

| Appropriate Weight Maintainer Rate: BMI 18.5 to less than 25 | 65.3% | 65.3% | 64.1% | 64.4% | Improve from previous FY |

| Smoking rate: Currently smoke cigarettes habitually | 17.8% | 17.4% | 17.4% | 13.7% | Reduce from previous FY |

| Rate of exercisers: Exercise twice a week for at least 30 minutes per activity. | 27.6% | 28.3% | 28.7% | 30.3% | Improve from previous FY |

| Rest through sleep: Sufficiently rested through sleep. | 71.2% | 68.8% | 70.1% | 69.0% | Improve from previous FY |

| Drinking habit rate: Frequency of occasional or daily drinking and amount of alcohol per occasion. | 12.9% | 14.8% | 15.8% | ー | Reduce from previous FY |

| Rate of employees with blood pressure risks: More than 180 mmHg systolic or more than 110 mmHg diastolic | 0.6% | 0.7% | 0.5% | 0.5% | Reduce from previous FY |

| Rate of employees at Risk for Blood Glucose: Fasting blood glucose 200 mg/dl or higher | 0.2% | 0.2% | 0.2% | 0.2% | Reduce from previous FY |

| Rate of employees with poor diabetes management: HbA1c 8.0% or more | 0.8% | 0.9% | 0.8% | 0.8% | Reduce from previous FY |

*Figures limited to Ricoh Company Ltd

Ricoh Recognized as a "Excellent Corporation for Health Management 2025" Large-Scale Corporate Sector

Ricoh Company Ltd, Ricoh Japan Corporation, Ricoh Industry Company, Ltd. ,and Hasama Ricoh, Inc. have been recognized as oneof the "Excellent Corporation for Health Management 2025" program sponsored by the Ministry of Economy, Trade and Industry(METI) in collaboration with the Japan Health Council. This is the 9th consecutive year that Ricoh has been recognized, and theRicoh IT Solutions Co., Ltd. has been certified for the sixth consecutive year as a "White 500" in the "Excellent Corporation forHealth Management 2025"

Building a framework for thorough occupational health activities (Managing physical and mental health)

Ricoh-Like Health Checkups

Since the 1970s, the Ricoh Group has been conducting regular health checkups for employees aged 35 and older through physical examinations. Since fiscal 2012, in addition to the legally stipulated items, we have been conducting new health checkups to prevent metabolic diseases and detect cancer in its early stages, and the health checkup rate has reached 100%.

Development of Industrial Health System

Since 2012, the scope of coverage has been expanded and rolled out to all Ricoh Group companies in Japan by standardizing the post-medical checkup follow-up and mental health care activities. At the same time, we are also focusing on improving the efficiency of activities and strengthening management by coordinating both physical and mental health care and cooperation with labor administration.

Physical Health Initiatives

(1) Countermeasures against infectious diseases

The Ricoh Group positions infectious diseases as one of its management risks. With regard to the outbreak of COVID-19 in 2019, we have been implementing infection prevention measures in offices and workplaces by utilizing the expertise of our industrial health staff and obtaining guidance from industrial physicians who specialize in infectious diseases. In addition, we have also worked to prevent illnesses and maintain and promote health while employees are working at home, also have provided consultation and other services to employees. Particularly for high-risk employees, we have taken additional measures as necessary to prevent serious illnesses, taking into account the nature of their jobs and duties.

In accordance with the Japanese Government’s downgrading of COVID-19 from "new influenza and other infectious diseases (so-called category 2 equivalent)" to "category 5 infectious diseases" on and after May 8, 2023, we are striving to ensure the same basic infectious disease prevention as for the other category 5 infectious diseases.

Going forward, we will formulate an all-round response standard that can deal with various infectious diseases and put in place systems and structures based on this standard so that we can respond more quickly and appropriately to any serious outbreak of infectious diseases that may affect the Ricoh Group and maintain the safety and health of our employees and employees of our suppliers, contractors and other cooperative partners.

(2) Smoking Prevention Measures

1) Smoking Prevention Policy in the Ricoh Group

In June 2014, we established the "Smoking Prevention Policy" and have been leading other companies in activities aimed at preventing passive smoking within the company and preventing health problems and promoting the health of people working in the Ricoh Group.

Ricoh Group Anti-Smoking Policy

~Ricoh Group's Policy on Smoking Prevention and Promotion of Health and a Comfortable Workplace through Smoke-Free Workplace

<Objective>

- Preventing health problems and promoting the health of Ricoh Group employees

- Preventing passive smoking within the company

- Coexistence with society and local communities

2) Efforts and results of anti-smoking measures

Based on the "Ricoh Group Policy on Smoking Prevention," various anti-smoking measures have been implemented. We have established a Smoking Prevention Project Group consisting of members selected from each company and business site, and have been conducting activities in cooperation with related parties. As a result, the smoking rate in fiscal 2024 was reduced by 6.9% for the Ricoh Group and 6.6% by Ricoh alone compared to fiscal 2017.

Anti-smoking activities

- Lectures on prevention of passive smoking and quit smoking by industrial physicians and others at Health and Safety Committee meetings

- Stopped selling cigarettes in the company (2013)

- Commencement of no smoking on premises and during working hours to promote health and prevent passive smoking (January 2015)

- Posting of "No smoking during working hours and in the office" on the Ricoh website pages for new graduate recruitment and career recruitment

*With the cooperation of not only Ricoh Group employees but also our partners who work for the Ricoh Group and customers who visit the Ricoh Group, we are making efforts with consideration for our neighborhood.

- Providing a variety of information on smoking through the company portal site, etc.

- Initiatives for "quit smoking" with respect for the will of the individual - " Quit Smoking Challenge Activities

- Interviews with occupational health staff to support employees in quitting smoking

- Assistance with costs for visiting stop-smoking clinics and for medications to help quit smoking, in cooperation with health insurance unions*.

Through a smoking cessation support program in collaboration with the health insurance association—including subsidies for nicotine gum and patches, as well as support from public health nurses—over 30% of participants at Ricoh have successfully quit smoking.

| Smoking rate (actual) | FY2017 | FY2024 | Improvement Rate |

|---|---|---|---|

| Ricoh Group | 29.3% | 22.4% | 6.9% |

| Ricoh Co., Ltd. | 18.5% | 11.9% | 6.6% |

*Responses according to the Lifestyle Survey

(3) Prevention of lifestyle-related diseases

The Ricoh Group has confirmed that it is difficult to improve blood glucose, in particular, among the legally mandated medical checkup items, simply by taking medication, etc., and is focusing its efforts on diabetes prevention.

(4) Cancer prevention measures

The Ricoh Group has incorporated cancer screening into health checkups for those aged 35 and older. In addition, we will implement the following measures to achieve a state in which each individual can positively engage in daily life and work by creating an environment in which treatment and work can be well-balanced.

- Correct understanding of cancer and cancer screening: Promote understanding of lifestyle habits to prevent cancer, how to receive health checkups for early detection and treatment, and treatment and physical and mental changes that may occur if a person is diagnosed with cancer.

- Ongoing verification on the ideal state of cancer screening: Verify the current state of cancer screening in light of the latest medical conditions.

- Establishment of a system to support balancing cancer treatment and work: Establish a system that involves the patient, family members, attending physicians, industrial physicians, workplace, human resources, etc., in order to balance treatment and work even if the patient has cancer.

- Support prevention awareness, raising the focus on breast and cervical cancers as women's health issues.

The rate of cancer screening in fiscal 2022 is as follows. There are cases in which employees do not undergo further detailed examinations even the findings are confirmed by cancer screening, or even if the occupational health staff recommends that they undergo the examination. We will work to further improve understanding of cancer and cancer screening and increase the screening uptake rate.

Cancer Screening Rate (2024)

Cancer Screening Rate(2024)

*Ricoh : 35 years old and over

Nationwide (based on the 2022 National Consumer Survey): 35-64 years old

At age 35, Ricoh employees undergo a gastric cancer screening that includes tests for Helicobacter pylori infection and gastric mucosal atrophy to assess their risk of developing gastric cancer. For those who test positive for H. pylori, risk reduction is promoted through eradication treatment subsidized by the health insurance association.

From age 36 onward, gastric cancer screenings are conducted every 1 to 5 years based on individual risk levels.

The screening rate for gastric cancer at Ricoh during milestone ages (in 5-year increments) is 78.2%.

(5) Measures to address women's health issues

To create a workplace environment in which women can play an active role, seminars focusing on women's specific health issues are held. We aim to create a comfortable working environment where everyone can work with vitality by raising women's health literacy, enabling them to take necessary measures such as consulting occupational health staff and visiting medical institutions when faced with health issues, and fostering a culture in the workplace where necessary consideration and support is (always) available.

Mental Health Initiatives

(1) Background of the initiatives

Ricoh has been providing individual follow-ups to employees with mental health problems by industrial psychiatrists for more than 30 years. In addition, regular meetings among industrial psychiatrists, the human resources department, and the health and safety department have been held to ensure that more appropriate measures are taken to those employees. Since 2005, we have built a health management system for employees working long hours in conjunction with work management and overtime management to strengthen measures against overwork. At the same time, we have enhanced the system by adding clinical psychologists to industrial physicians, nurses and certified public psychologist.

(2) Self-care

In 2007, Ricoh was one of the first to introduce stress checks, which later became mandatory legislation, and in 2009, we provided self-care e-learning to all Ricoh Group and new employees. In addition, we are working to create an environment where employees can work with peace of mind by providing an easy access to online counseling services. In addition, for employees transferred overseas, in consideration of working and living environments that differ significantly from those in Japan and the health support system in the new location, we conduct interviews with the occupational health staff in charge of overseas operations and lectures on mental health by occupational physicians prior to their transfer to the new location.

(3) Line Care

In 2006, we started e-learning for all organizational managers to learn the basics of HR and labor management and the fundamentals of line care, as well as training in attentive listening to ensure smooth communication with team members, as part of our efforts to prevent overtime work. Since then, the training has been conducted on an annual basis for newly appointed organization managers.

Since 2011, we have conducted workplace management training by industrial physicians to learn how to manage employees with mental health problems based on case studies, providing an opportunity to learn how to manage such employees and to strengthen cooperation between industrial physicians and organization managers.

Since 2017, we have begun to expand the program to Ricoh Group companies, and are regularly conducting line care training for organizational positions other than newly appointed employees.

In fiscal 2020, we will conduct more practical online interactive line care training, taking into account the increasing use of remote work in a variety of positions. The training is designed to provide an opportunity for participants to discuss and receive advice on line care directly from industrial physicians.

Managers taking Line Care Training

Health Promotion Activities

Based on the health issues arising from the business operations and workforce composition of each company and business site, we are planning and developing "health promotion activities" from the perspectives of exercise, diet, sleep, etc.

In addition to ongoing efforts (introduction of healthy menus, labeling of calories and salt content, training sessions, etc.) in collaboration with the company that operates the cafeterias at business sites on consignment, the following initiatives were implemented in consideration of the health impact of telecommuting and to further maintain and promote health in a self-regulated manner. The following initiatives have been implemented to further maintain and promote the self-regulating health of employees.

In addition, we encourage our employees to actively make the most of rework through resources outside the workplace, and we have been implementing measures to support their reinstatement so that they do not repeat absences from work.

- Provision of healthy meal options at cafeterias aimed at improving lifestyle-related diseases and preventing frailty, along with lectures by registered dietitians.

- Video streaming of health promotion videos (external online seminars, stretching instruction by in-house corporate sports department staff)

- Distribution of "Health Promotion Programs to encourage continuous exercise and improvement of dietary habits," planned by the health insurance association

- Distribution of "Dietary guidance using time nutrition (quiz format)" newsletter for new employees

- Implementation of walking and health improvement campaigns to help establish regular exercise habits.

- Promotion of health literacy to prevent fall-related accidents, and provision of exercise guidance that can be easily practiced anywhere.

- Measurement of body composition balance, basal metabolic rate, bone health, and grip strength to help individuals understand their physical condition and raise health awareness.

- Implementation of dental and oral health seminars focusing on issues such as cavities and periodontal disease.

Health Management System

In order to promote effective and efficient management processes related to health management, we have established a common group-wide system linked to key HR information. The system serves as an information management and operational efficiency tool for industrial health staff working at multiple sites nationwide.