- Home

- Ricoh's Technology

- Rewritable Laser System

Rewritable Laser System

Ricoh has successfully developed a technology that enables non-contact, high-speed rewriting of labels used in logistics returnable containers, which can be rewritten approximately 1,000 times while still attached to the container. These labels can be used repeatedly for more than five years under harsh outdoor conditions, contributing significantly to environmental impact and cost reduction. (The rewritable laser system is available only in Japan at this time.)

This rewritable laser system won the Technology Prize from the Imaging Society of Japan in 2013.

Development Background

Rewritable recording technology has attracted a great deal of attention due to its convenience and reduced impact on the environment; various methods have been proposed in the past. In particular, thermal rewritable recording media using heat were put to practical use early on and have been widely used for card display applications, such as displaying numbers and expiration dates on loyalty cards, IC cards, and the like, using the thermal head recording method. Furthermore, studies have been conducted to apply rewritable recording technology to industrial applications, such as factory automation and logistics. For example, in logistics, where regular deliveries are made, barcodes and text information indicating the delivery address and contents are printed on labels using a printer and attached to returnable containers for each shipment to ensure accurate delivery. When the tote container is returned, the labels are peeled off and discarded, and new thermal labels are applied.

If these discarded labels can be replaced with rewritable recording media, it reduces the impact on the environment by reducing waste and CO2 emissions. In addition, the system significantly improves operational efficiency by reducing labor costs associated with label replacement and the risk of logistics system problems caused by label residue. However, printing on media that has been deformed from long-term use on reusable containers is difficult when using a contact-type thermal head recording. In addition, conventional rewritable recording media for cards cannot provide high light resistance performance in direct sunlight outdoors, which is required for logistics applications.

Ricoh has resolved these issues for use in harsh outdoor conditions with its proprietary technology, making rewritable recording available for logistics applications.

Basic Configuration and System Features

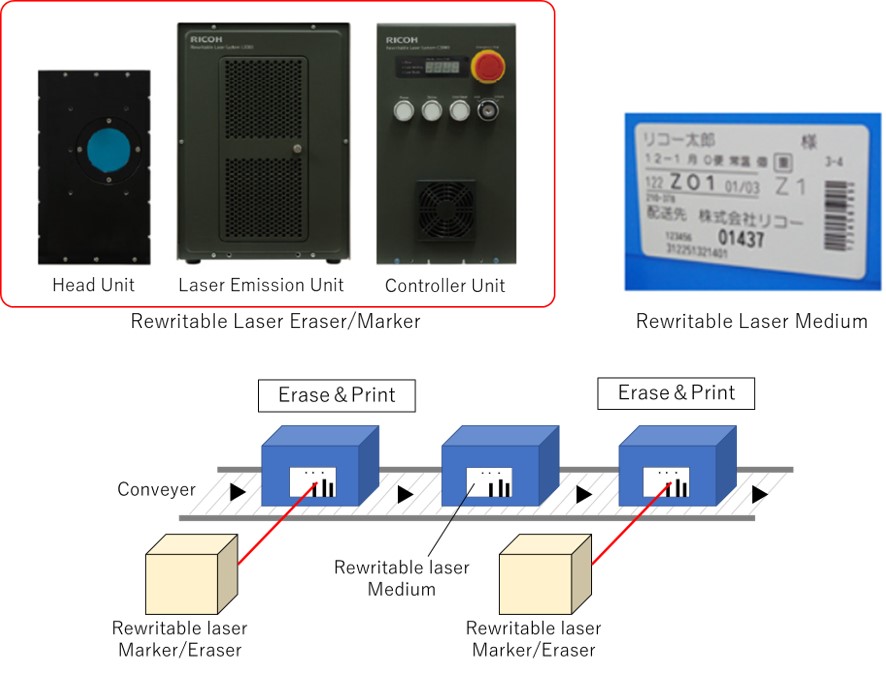

The “Rewritable Laser System” is a non-contact rewriting system using lasers developed by Ricoh consisting of a rewritable laser marker/eraser that improves reproducibility by making the optical distribution uniform and a rewritable laser medium with improved light resistance. (Figure 1).

Figure 1: Ricoh rewritable laser system and an example of contactless rewritable recording medium pasted on tote containers that ride on a belt conveyor.

Device Configuration and Rewritable Laser Printing / Erasing Machine Features

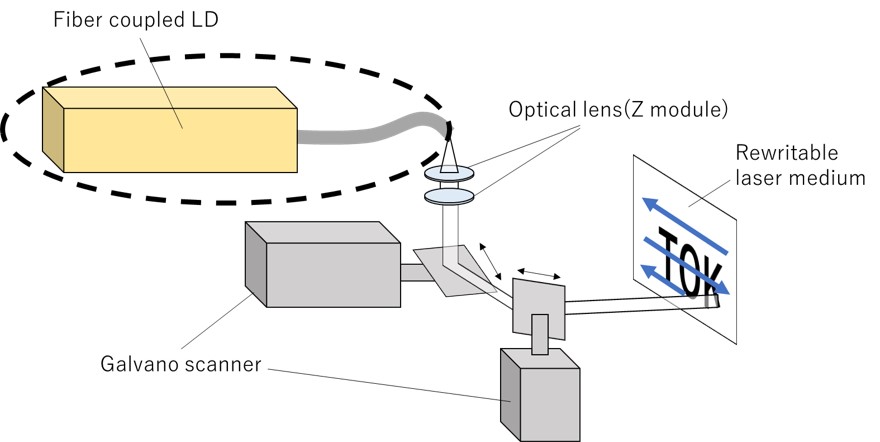

Figure 2 illustrates the optical system for a rewritable laser marker. The laser beam (maximum output power 125W) emitted from a laser diode (LD) through an optical fiber passes through an optical lens and create a circular beam through two galvano scanners positioned at 90 degrees angles. The laser is emitted to the rewritable laser media heating the media to over 180°C and drew a line width of about 0.25 mm on the media. The galvano scanner changes the laser beam angle, which prints characters using vector scanning, that traces the laserbeam as if drawn with a pen.

Figure 2: Basic configuration of rewritable laser printing/erasing machine

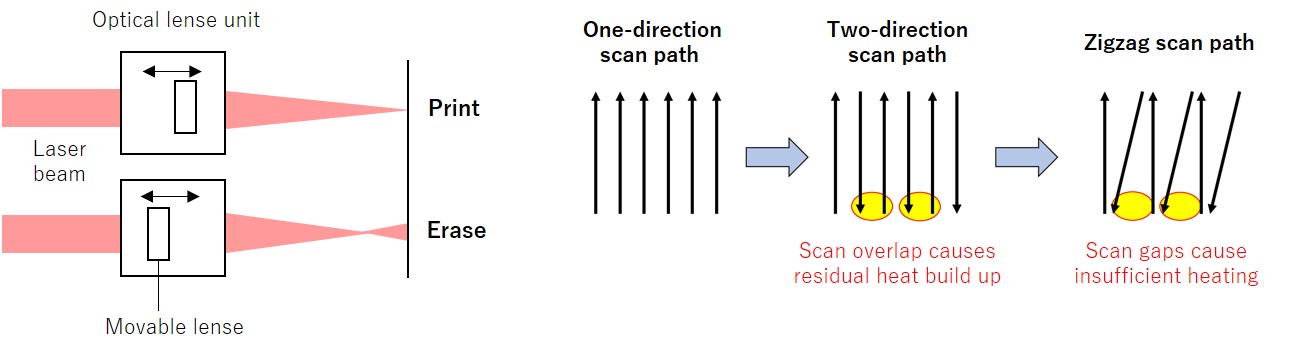

The images on a rewritable laser medium are erased by heating at 130℃ to 170℃, lower than the color-developing temperature. To heat the entire surface of the media uniformly and quickly within this temperature range, a heating method using a circular beam scanning two-dimensionally with a larger beam diameter is used during erasure. The beam diameter is controlled by defocusing with an optical lens (Z module). We use reciprocal scan, which minimizes jumps during scanning to shorten the erase time, and adopt reciprocal zigzag scan to avoid excessive overheating of the folded area, achieving both shorter erase time and improved repetition durability.

Figure 3: Comparison of defocus control (left) and optical lens (Z module) scanning method (right)

In addition, we provided the distance adjustment and the laser beam scanning speed adjustment mechanisms on the marker and eraser. The purpose was to improve the practicality in logistics applications and to respond to deformation and various sized tote containers. Further, we have developed and introduced our unique laser energy control mechanism by detecting medium temperature into both the marker and the eraser.

General laser markers are devices that can print on various materials without contact, such as plastic and metal, and are widely used in production plants for print numbers and dates on products. However, the Laser Marker’s beam has a sharp peak distribution (Gaussian distribution). When printed on rewritable media, excessive heat is applied to the center of the printed line, and repeated printing and erasing degrades the media, resulting in residual images.

Ricoh’s laser markers have achieved a uniform optical distribution (Top Hat) with even light intensity in the center and periphery by devising its optical system. As a result, the line to be printed is heated uniformly, and excessive energy is not applied to the center of the printed line, enabling high-speed printing without degrading the media.

High visibility printing on medium

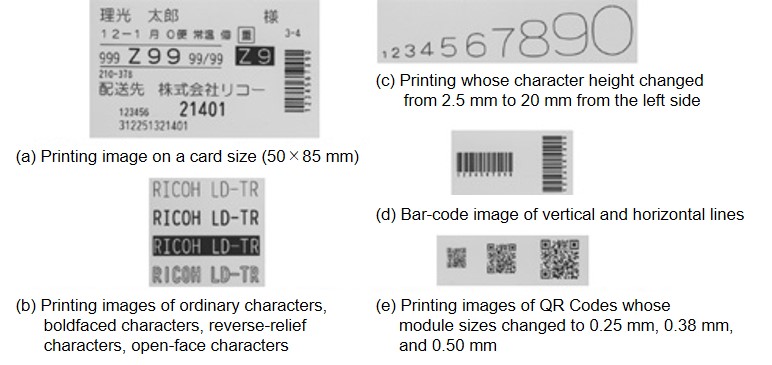

The vector scan printing method, in which the laser beam is traced by the laser marker as if a pen drew it, can create smoother character images compared to the raster scan method, in which the heating is turned on and off in pixel units using a thermal head, enabling highly legible printing. As shown in Figure 4, the rewritable laser marker can produce various printed images to meet market requirements. Figure 4(a) is an example of an image used in logistics, in which barcodes, letters, numbers, and other images necessary for logistics management functions can be cleanly printed. In contrast to thermal head printing, which results in lower barcode quality for horizontal lines, the vector scanning method used in this system ensures the same high print quality for both vertical and horizontal lines, as shown in Figure 4(d).

Figure 4: Various printing images printable with rewritable laser system

Light stability improvement technology of medium

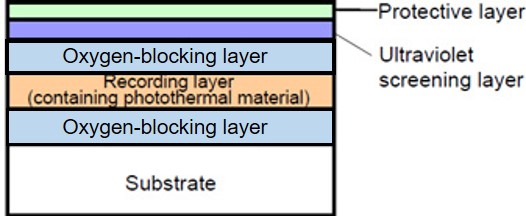

For outdoor logistics applications where the media is exposed to changes in weather and temperature, high light resistance is required to withstand direct sunlight. Conventional rewritable media for thermal printheads (TPH) suffers from reduced image density and discoloration of the substrate when exposed to direct sunlight and fading after image erasure. The cause of this performance degradation is the decomposition of the leuco-dyes in the recording layer by ultraviolet light and oxygen. In the laser diode recording method developed by Ricoh, a thick layer that can transmit near-infrared laser light is formed above the recording layer. As shown in Fig. 5, a UV blocking layer is formed on the recording layer by synthesizing a new UV absorber that blocks UV light below 400 nm and allows visible light to pass through. Furthermore, by forming oxygen-blocking layers that shield the recording layer from oxygen, rewritable laser medium with high light resistance has been created.

Figure 5: Basic configuration of rewritable laser medium (different from product layer configuration)

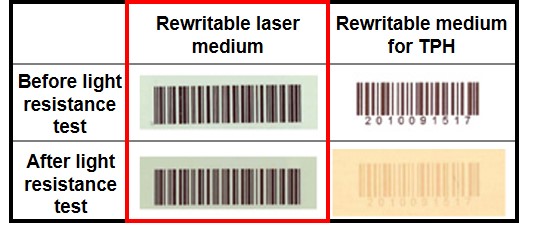

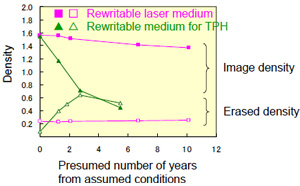

Figure 6 (a) shows samples of the light resistance test results with the rewritable laser media and rewritable media for TPH. Figure 6 (b) shows the change in image density and erased density. The light resistance test is conducted by an accelerated test using xenon light irradiation. 256 hours of xenon light irradiation is equivalent to 5 years of outdoor logistics use. For rewritable media for TPH, after the light resistance test, the image fades, the substrate turns yellow, and the contrast is reduced drastically. In contrast, there is little change in the image of rewritable laser media before and after the test. This is evident from the graph of the density measurement results in Figure 6(b).

In addition, the barcode characteristics of the rewritable media for TPH were graded “F” (unreadable by barcode scanners) after the light resistance test, while the rewritable laser media was able to maintain a “C” grade required for logistics applications, indicating that it can be used for more than five years in outdoor logistics applications.

(a) Light resistance test result corresponding to five years

(b) Change of image density and erased density by light resistance test

Figure 6: Difference in light stability of medium between rewritable laser medium and rewritable medium for TPH

Repetition durability improvement technology for media

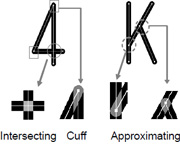

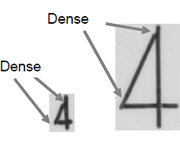

The vector scan printing method, in which a laser beam is traced by a laser marker as if a pen drew it, is widely used in factory automation applications, etc., because it has the advantage of being able to draw characters faster than the raster scan method, in which characters are expressed by many dots, and also because it can draw the outline of characters smoothly. However, if the character data of a standard laser marker is used as-is for drawing with a rewritable laser system, the intersection and folded portions are heated multiple times, as shown in Fig. 7. This causes excessive heat to be applied to the area, which eventually reaches the degradation temperature of the material, causing the media to deteriorate and leaving a visible residue, which is a recurring durability issue.

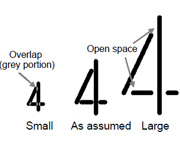

If overlapping can be eliminated, the excessive heat rise issue can be solved. Although steps can be taken in rending the font image beforehand to remove the overlap, as the character size and line width change with system setup, enormous time and effort is needed to render the font where the overlap part is removed in the right proportion. Moreover, when fonts were created with the line width and character size in mind to avoid overlaps, as shown in Fig. 8, overlaps remain or gaps were opened depending on the magnification rate of the characters, resulting in lower quality. To solve this problem, Ricoh has developed software that automatically removes overlapping parts of character data according to the size and line width of the character, thereby achieving a laser beam scanning control technology that can draw high-quality characters without excessive temperature increase. Using a rewritable laser marker equipped with this technology, even if characters are drawn in different sizes, as shown in Fig. 9, there are no gaps and overlaps are eliminated, resulting in improved legibility as well as improved repetition durability.

Figure 7: Example of multiple heatings of intersection or cuff part (turned edge)

Figure 8: Example of fonts created,

overlap removed and character size changed beforehand

Figure 9: Image with overlapping areas automatically removed based on the size of the text.

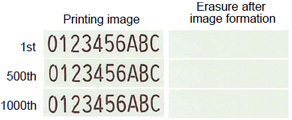

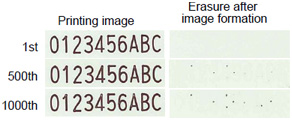

Fig. 10(a) shows the results of 1,000 printing and erasing cycles on rewritable laser media using a rewritable laser marker with embedded character drawing data generation software that automatically removes overlapping parts of character data. Erasure was done using the rewritable laser eraser. Figure 10(b) shows the result of printing and erasing without removing overlaps. When overlap is not removed, the intersection and cuff part remains as a black spot. However, when the overlap is removed, uniform erasure is achieved even after 1,000 times, demonstrating medium durability.

(a) Printing and erasure after overlap removal

(b) Printing and erasure, without overlap removal

Figure 10: Effect of improved repetitive durability of overlap removal

Effects of introduction of the rewritable laser system

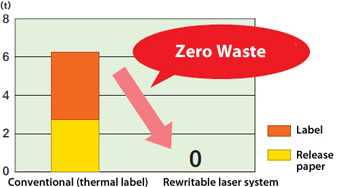

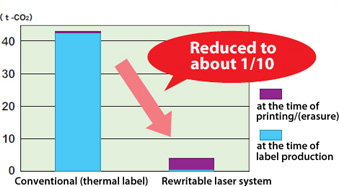

This technology enables rewritable recording, thereby helping protect the environment in wider fields and increase business efficiency. In logistics, the current method of labeling reusable containers is to use an automatic labeler to print and apply thermal labels, and when the container is returned, the labels are peeled off, and new labels are printed and applied, generating waste. A rewritable laser system equipped with this technology will be able to rewrite approximately 1,000 times. Since the system can be used without being replaced for almost the same period of time as the life of a reusable box (several years), label waste during the period of use is zero (Fig. 11), and CO2 emissions are about one-tenth (Fig. 12). This system will greatly contribute to reducing environmental impact. If this system can be expanded to all logistics applications where reusable containers are currently used in Japan, it is estimated that the volume of thermal paper labels can be reduced by approximately 4,800 tons per year.

Figure 11: Amount of disposed label waste for five years of

middle-scale physical distribution center

Figure 12: Amount of CO2 emissions for five years of

mid-size physical distribution center

In addition, conventional thermal labels usually require the labels to be manually removed, which adds to the labor cost. Moreover, problems such as forgetting to remove the barcode or leaving the previous barcode intact due to human intervention have occurred, leading to troubles in the sorting system of the logistics companies. Using the rewritable laser system, the labor costs for label removal can be reduced, and system problems caused by leftover label removal can be eliminated, resulting in a significant efficiency improvement in logistics operations.

References

1) Y. Hotta, A. Suzuki, T. Kitamura, T. Yamaoka: Laser Recording on Thermo rewritable Marking Media, Journal of Electrophotography, Vol.35, 168 (1996) [in Japanese].

2) T. Asai, F. Hasegawa, M. Tsuchiya, S. Kawahara, K. Yamamoto, T. Ishimi, T. Furukawa, Y. Hotta:Improvement of Light Durability and Repetition Durability of Thermal Rewritable Media by a Recording Process using Laser Diode, RICOH TECHNICAL REPORT, No.36 (2012) [in Japanese].

3) S. Kawahara, T. Ishimi, Y. Hotta: Laser Recording on Thermal Rewritable Media (1)-Improvement of repetition durability by controlling intensity distribution of the laser beam-, Proceeding of Imaging Conference JAPAN 2007, 51 (2007) [in Japanese].

4) T. Ishimi, S. Kawahara, T. Asai, Y. Hotta: Laser Recording on Thermal Rewritable Media (2) Simulation of Thermal Distribution and Control of Intensity distribution Using the Optical Lens, Proceeding of Pan-Pacific Imaging Conference 2008, 390 (2008).

5) T. Asai, S. Kawahara, T. Ishimi, Y. Hotta: Laser Recording on Thermal Rewritable Media (3) Improvement of Light Durability by a Recording Process using Laser Diode, Proceeding of Imaging Conference JAPAN 2010, 223 (2010) [in Japanese].

6) T. Furukawa, F. Hasegawa, M. Tsuchiya, K. Yamamoto, T. Asai, T. Ishimi, Y. Hotta: Laser Recording on Thermal Rewritable Media (4) Improvement of Repetition Durability by a Laser ray Scanning Control Process using Laser Diode, Proceeding of Imaging Conference JAPAN 2012, 255 (2012) [in Japanese].

7) M. Tsuchiya, F. Hasegawa, T. Furukawa, K. Yamamoto, T. Ishimi, T. Asai, Y. Hotta: Laser Recording on Thermal Rewritable Media (5) Imaging Technology of Barcode and 2D Code by a Scanning Control Process using Laser Diode, Proceeding of Imaging Conference JAPAN 2013, 283 (2013) [in Japanese].

Sorted by : field “Thermal Media” “Resource Conservation” | product type “Thermal Media” “Environment”