- Home

- Ricoh's Technology

- Application of Transfer Learning for Prediction of the Quality of the Chemical Toner Manufacturing Process

Application of Transfer Learning for Prediction of the Quality of the Chemical Toner Manufacturing Process

In recognition of its efforts using this technology, Japan's Ministry of Economy, Trade and Industry and the Tokyo Stock Exchange jointly selected Ricoh as one of the “Digital Transformation Stocks (DX Stocks) 2022.” The company also received the Technology Award at the Society of Instrument and Control Engineers (SICE) Awards 2022.

Background

In recent years, the manufacturing industry has actively engaged in digital transformation by developing data collection technology using the Internet of Things (IoT) and data analysis techniques using machine learning.

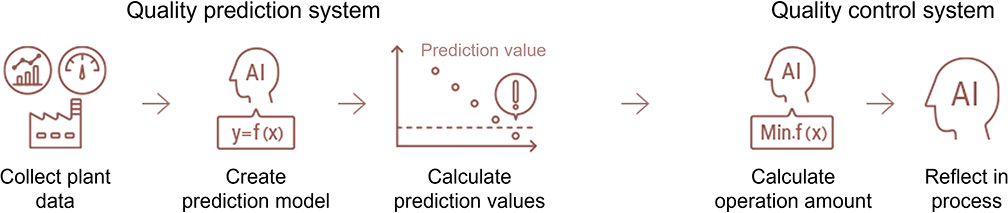

In Ricoh's chemical toner manufacturing process, skilled engineers perform quality control manually based on their know-how. This requires many person-hours for process monitoring and operation amount instructions and places a high mental burden on the employees because control errors could lead to significant losses. By introducing an automatic toner quality control system*1 that utilizes machine learning, we have created a process that does not rely on the know-how of skilled engineers, thereby improving productivity.

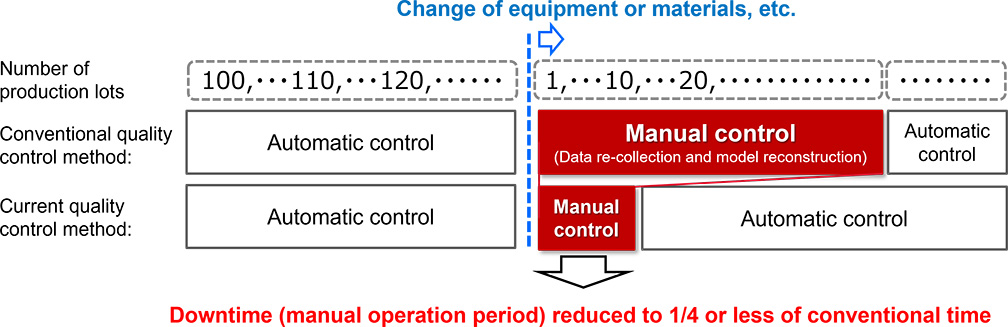

However, in the manufacturing process, improvements are often made to production equipment and raw materials to reduce the environmental impact and improve quality. Each time such improvements are made, a new machine learning model must be constructed, but this requires long-term data re-accumulation, and during this period, we have to rely on manual quality control. Therefore, technology for building high-performance machine learning models using short-term data was required.

- *1

- System that enables stable quality to be obtained by automatically optimizing key manufacturing conditions based on quality prediction results calculated by a machine learning model

Solutions

We have achieved high prediction accuracy with significantly less training data by developing our transfer learning technology and applying it to past similar data.

When we applied this technology to a mass-production plant for chemical toner, the downtime of the automatic quality control system during the model reconstruction period was reduced to less than a quarter of the conventional time.

Technical highlights

This advancement consists of the following two technologies.

1. Technology that utilizes similar data from the past (transfer learning)

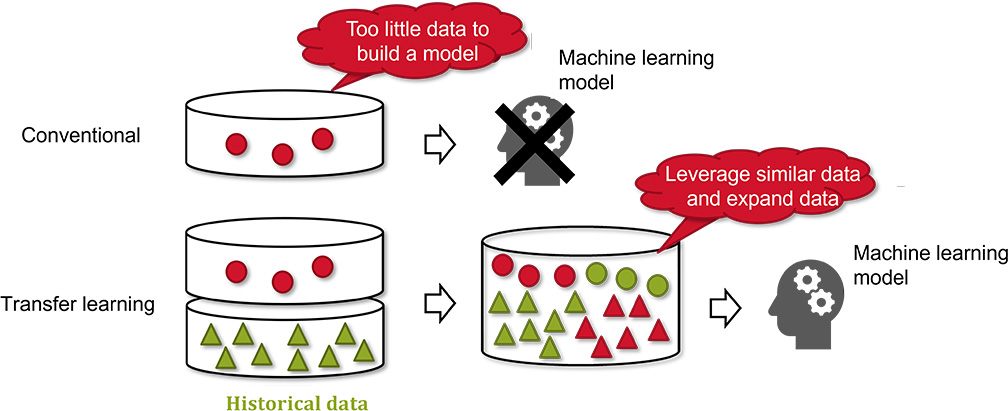

Transfer learning is defined as “a method of utilizing knowledge of a task as well as knowledge of another similar task to improve the accuracy of a task.” Most conventional transfer learning methods are challenging to use in manufacturing, because both tasks have the same data structure and require advanced knowledge of machine learning.

Ricoh's new transfer learning method—Frustratingly Easy Heterogeneous Domain Adaptation (FEHDA) —uses a method that transfers the data. This technology allows using important knowledge from past data through simple data expansion, even when the data structure differs between the two tasks before and after a change in production equipment or raw materials.

2. High-performance quality prediction technology

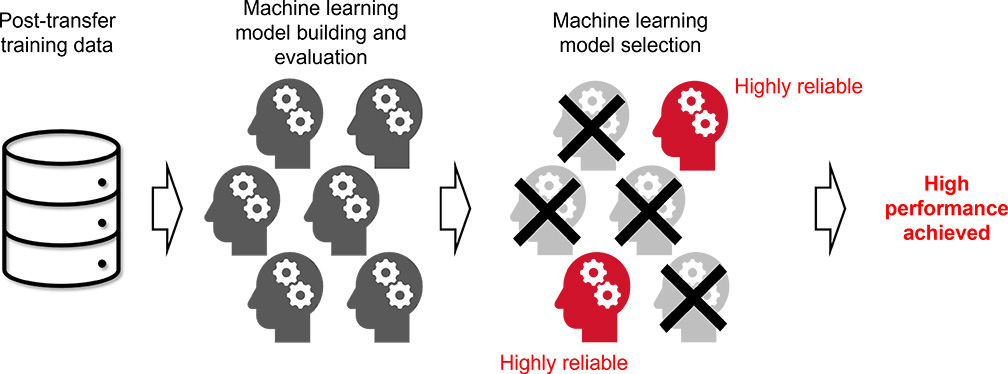

One way of combining machine learning models to make predictions is “bagging.” Through this method, multiple machine learning models are processed in parallel, and a conclusion is drawn from the average or majority vote of these learning results.

This technology selects models with particularly high prediction reliability from multiple machine learning models via bagging and combines them to realize the construction of high-performance machine learning models.

This technology was developed jointly by Professor Manabu Kano of the Department of Systems Science, Graduate School of Informatics, Kyoto University, and Mr. Toshiaki Sato of MEIWA e-TEC Co., Ltd., who provided technical guidance.

Ricoh's vision

At Ricoh, engineers with field expertise are learning data science to examine and realize DX-based production innovation throughout the supply chain and engineering chain.

We will continue to work on utilizing digital technologies that contribute to the transformation of productivity and work styles in the field and the office.

- *

- All other company and product names and logos in this document are the trade names, trademarks, or registered trademarks of their respective companies.

Related information

Automatic Quality Control for Chemical Toner Using Machine Learning Prediction (PDF: P8/1.66MB)

Application of Transfer Learning to Chemical Toner Quality PredictionSource: The 35th Annual Conference of the Japanese Society for Artificial Intelligence, 2021

Transfer Learning for Quality Prediction in a Chemical Toner Manufacturing ProcessSource: Computer Aided Chemical Engineering (Volume 49, 2022, Pages 1663-1668)

Sorted by : field “Electrophotographic” “AI (Artificial Intelligence)” “Production Systems” | product type “Ink / Toner”