- Home

- Technology

- Ricoh's Technology

- PLAiR – A New Material Made from Plants and Air

PLAiR – A New Material Made from Plants and Air

Background

As worldwide climate change due to global warming and environmental pollution caused by waste become societal issues, the need to promote alternatives to plastics derived from fossil resources is becoming urgent. To work toward building a decarbonized, recycling-oriented society under its environmental management policy, the Ricoh Group has been using biomass plastics made from polylactic acid (PLA) since the late 1990s. Made from plant-derived starch and sugar, these plastics are used in components for multifunction devices and other products. Using PLA, plant-based, compostable material as a primary component, we have worked to develop a new kind of foam sheet.

Solution

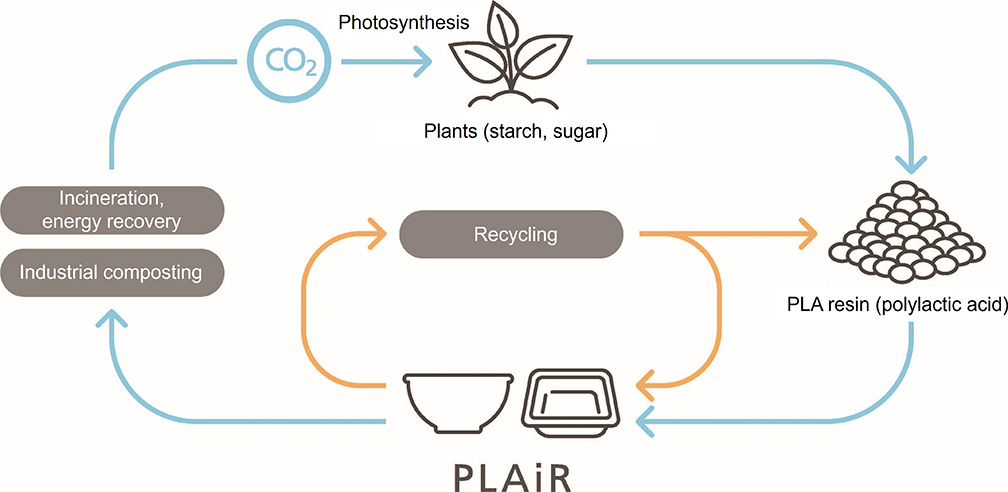

PLA is a plant-based plastic material made from plant sugars. When, for example, the material is incinerated, CO2 will be emitted during the process. However, the material, which is made from plants, absorbs CO2 as they grow, thus creating a lifecycle with a low environmental impact. In addition, PLA is compostable, meaning it can be decomposed into water and CO2 under certain environmental conditions. Despite these characteristics, PLA is generally considered difficult to turn into foam, and its cost is higher than that of plastics derived from fossil resources, so it has only been introduced into the market in limited amounts.

Using proprietary “supercritical CO2 foaming control technology,” Ricoh has developed foamed PLA sheets that contain evenly distributed air. These foamed sheets are expected to reduce the weight of products, conserve resources, and provide thermal insulation, and they can be molded and processed into a wide variety of trays and containers.

Foamed PLA sheets allow brand owners to use biomass plastics in a variety of situations while at the same time gaining trust in the ESG investment market and contributing to society through their environmental business.

In addition, since the material can be molded into a variety of shapes, converters can expand their businesses by using it for a wide range of applications, including food containers, packaging, and trays for business use.

- *

- Tested at 58°C and in the presence of aerobic microorganisms, in accordance with JIS K6953-2

The cycle we aim to realize with PLAiR

Technical highlights

Ricoh has succeeded in foaming plant-derived PLA with supercritical CO2 foaming control technology, PLAiR Foaming Technology. This has led to the creation of foamed PLA sheets, PLAiR.

PLAiR—light but durable foamed PLA sheets

PLAiR—light but durable foamed PLA sheets

By foaming the material, users can expect to reduce the weight of products, save resources, and provide thermal insulation. However, foamed PLA has not been widely used due to the difficulty of the foaming process.

Ricoh has developed a supercritical CO2 foaming control technology, which we call PLAiR Foaming Technology, to facilitate PLA foaming.

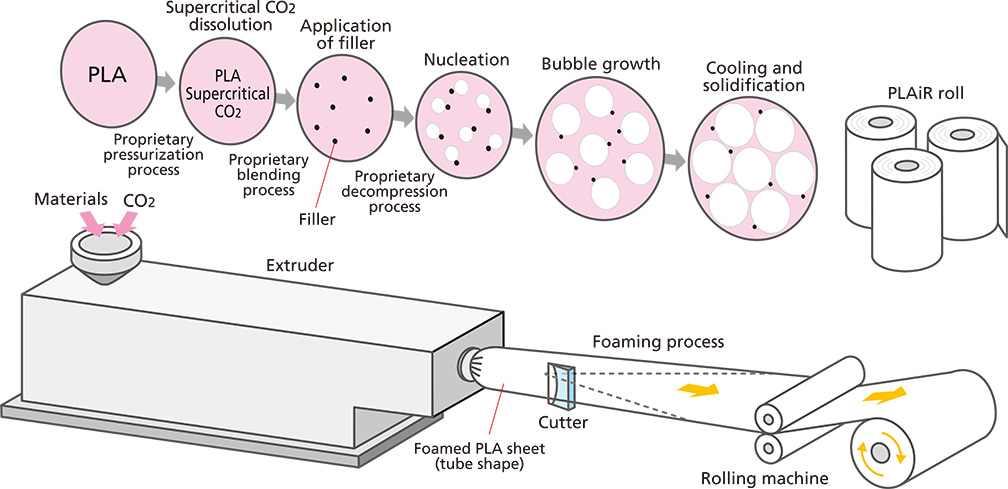

Supercritical CO2 is a fluid that has the diffusivity of a gas and the solubility of a liquid. The fluid is formed by applying a certain level of heat and pressure to CO2. Supercritical CO2 is used as a foaming agent in the processing of materials. In addition, we have made it possible to produce foamed PLA sheets by controlling foaming through a combined approach that takes into account the material, foaming technology, and equipment. This approach includes the use of fillers (foaming nucleating agents), consideration of extrusion conditions, and optimization of the mold structure.

Features of PLAiR Foaming Technology

1. Viscoelasticity control of PLA in extrusion foaming equipment

In extrusion foaming, one of the methods used to manufacture foamed sheets, it is necessary to control the viscoelasticity of the resin to keep it within a suitable range. If the viscosity is too high, bubble generation and growth will be inhibited, and if it is too low, the foam will burst. PLA tends to have low viscosity when melted, making foaming generally difficult. However, by controlling both the conditions of the foaming process and the composition of raw materials, we have succeeded in controlling the viscoelasticity in a manner suitable for foaming.

Conceptual image of PLAiR Foaming Technology

Conceptual image of PLAiR Foaming Technology

2. Controlling the foaming phenomenon in extrusion foaming equipment

When foaming occurs inside the extrusion foaming equipment, appearance defects such as wrinkles and surface roughness can appear to occur on the sheets. To address this issue, we continuously improved the equipment and the conditions of the foaming process to prevent foaming from occurring inside the extrusion foaming equipment, thereby ensuring that the foaming phenomenon occurs at a stage when the sheet has been extruded from the extrusion foaming equipment. As a result of this process, we have succeeded in producing sheets with a homogeneous surface free from wrinkles and roughness.

Wrinkles

Wrinkles

Surface roughness

Surface roughness

Sheet with improved surface properties

Sheet with improved surface properties

3. Controlling the diameter of the bubbles

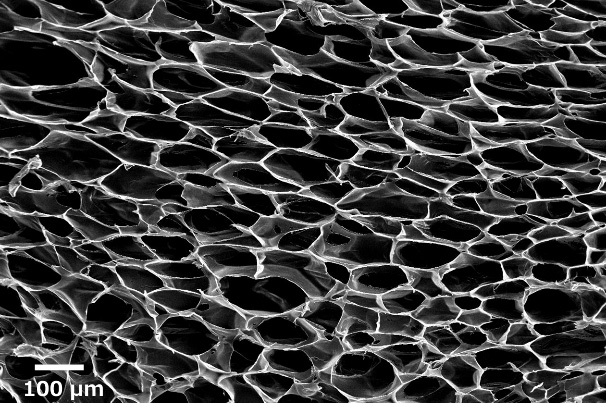

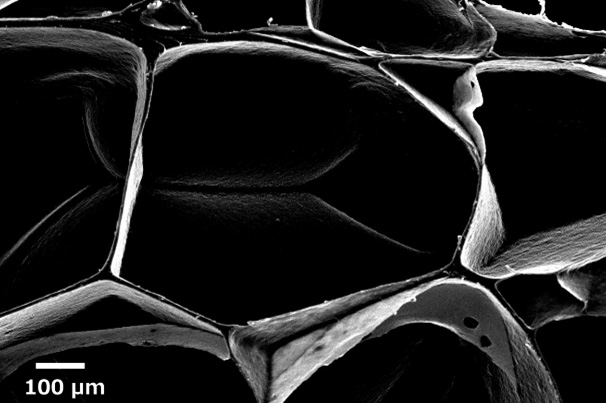

By controlling the diameter of the bubbles, the flexibility and strength of the sheets can be changed. This makes it possible to produce soft and flexible sheets as well as hard sheets suitable for molding applications.

Cross-sectional image of PLAiR sheets The diameter of the bubbles can be controlled to be between several tens of micrometers to several millimeters in length.

Ricoh's Vision

We named this new material PLAiR, which is a combination of the words “plant” and “air,” from which the material is made. Created with the mission of realizing a decarbonized and recycling-oriented society, PLAiR is a new environmental product designed for a future in which it can be used reliably as a commonplace material.

Food containers made with PLAiR

Food containers made with PLAiR

Relevant Contents

Sorted by : field “Resource Conservation” “Pollution Prevention” “Materials”