- Home

- Ricoh's Technology

- Ink for Offset Coated Paper

Ink for Offset Coated Paper

Ricoh has developed a new ink for the RICOH Pro VC Series high-speed full-color inkjet continuous form printing system. The ink can be used on offset coated paper without the need for any pre- or post-processing. As undercoat and protector coat liquids are no longer required, running costs and the costs of a liquid application system are reduced significantly. Further, the color gamut has been increased significantly; the image quality now compares favorably with offset printing.

Background

Offset coated paper absorbs little water-based ink. In the past, pre- and post-processes were required to prevent adjacent ink dots from being blended and causing blurs and roughness: an undercoat liquid would be applied before the printing to help the ink harden, and a protector coat liquid would be applied after the printing to protect the ink layer.

Printing on offset coated paper was costlier than printing on normal paper because of those liquids. Users wanted an ink that could be used on offset coated paper in the same way as on normal paper, thus eliminating the costly pre- and post-processes.

Solutions

With Ricoh's newly developed ink, it is no longer necessary to use the undercoat and protector coat liquids. The ink can be used directly on offset coated paper. By reducing the supplies required it greatly reduces running costs. Because no liquid application system is necessary either, the upfront investment is also reduced.

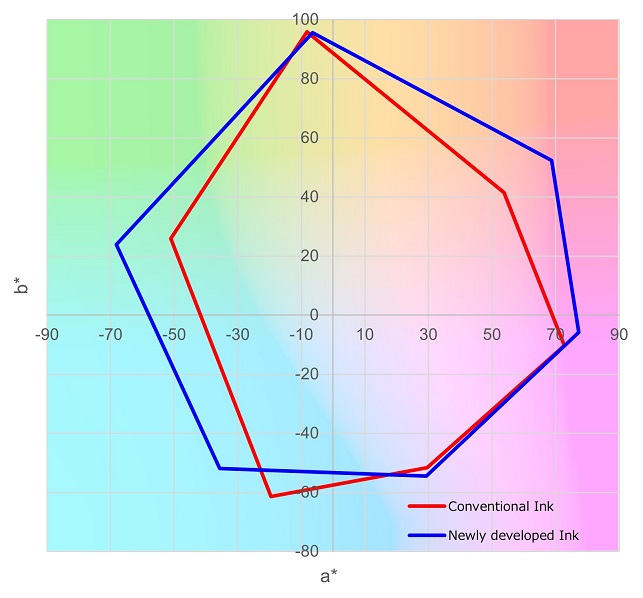

With the enhanced color gamut, this ink enables high quality images that are comparable to offset printing.

Newly developed ink

Newly developed ink

Conventional ink

Conventional ink

Printed images (without undercoat)

Technical highlights

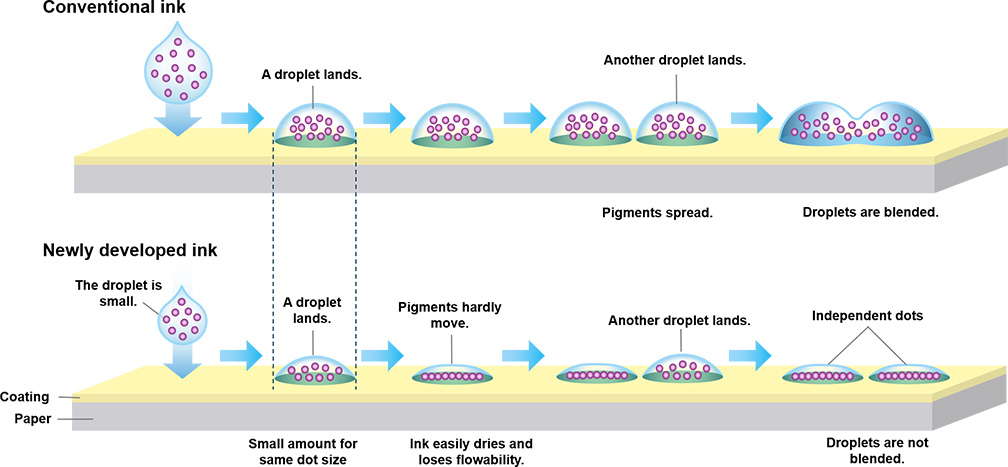

Offset coated paper is not very hydrophilic (not good at absorbing) and thus not compatible with water-based ink. Generally, when water-based ink is used on offset coated paper, ink droplets hardly spread over the surface, therefore a lot of ink is required in order to form a dot large enough to reproduce an image.

Ricoh has increased the wetness of the ink so that it spreads over the surface of the offset coated paper; small ink droplets now form large dots when they hit the surface. Thus, only a small amount of ink is required to reproduce an image.

In addition, Ricoh has improved the drying properties of the ink. With this ink that dries easily when used in small quantities, the printed image also quickly dries. The flowability of the ink is lowered very quickly.

Thanks to the low flowability, dots are less likely to blend than before, which means fewer blurs and less roughness. As a result, an undercoat liquid is no longer required.

Image forming processes of conventional and newly developed inks

Image forming processes of conventional and newly developed inks

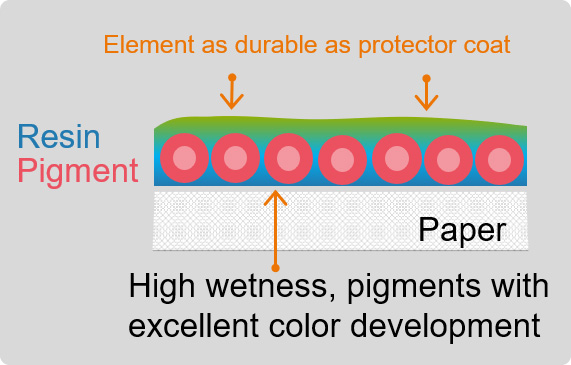

The ink even functions as a protector coat liquid, increasing durability of the ink film. Post-processing with a protector coat liquid is no longer required.

Cross section of an image printed with the new ink

Cross section of an image printed with the new ink

Ricoh's pigment distribution technology suppresses coagulation of pigments during the drying process. It has improved color development, expanded the color gamut and enhanced color reproduction.

Color development of different methods

Color development of different methods

Ricoh's vision

Inks for the RICOH Pro VC series meets the requirements of an inkjet printer in the commercial printing market: quality image, high productivity, and low cost. Ricoh is committed to delivering its inkjet technologies to a wide variety of high quality printing applications, including catalogs and magazines, where offset printing has been dominant. Ricoh's inkjet technology meets the requirements of the printing industry even in area where high-quality printing is demanded.