- Home

- Technology

- Ricoh's Technology

- Biomass Plastic Material Technology

Biomass Plastic Material Technology

Ricoh has been quick to focus on biomass plastics as a material that contributes to preventing global warming while reducing petroleum consumption, an exhaustible resource. As a result, we have been cultivating new technologies and applying them to produce materials.

Ricoh has been developing components of imaging devices that utilize biomass plastics as a part of its effort to develop alternative materials while considering the best manufacturing methods to support a low-carbon and recycle-oriented society.

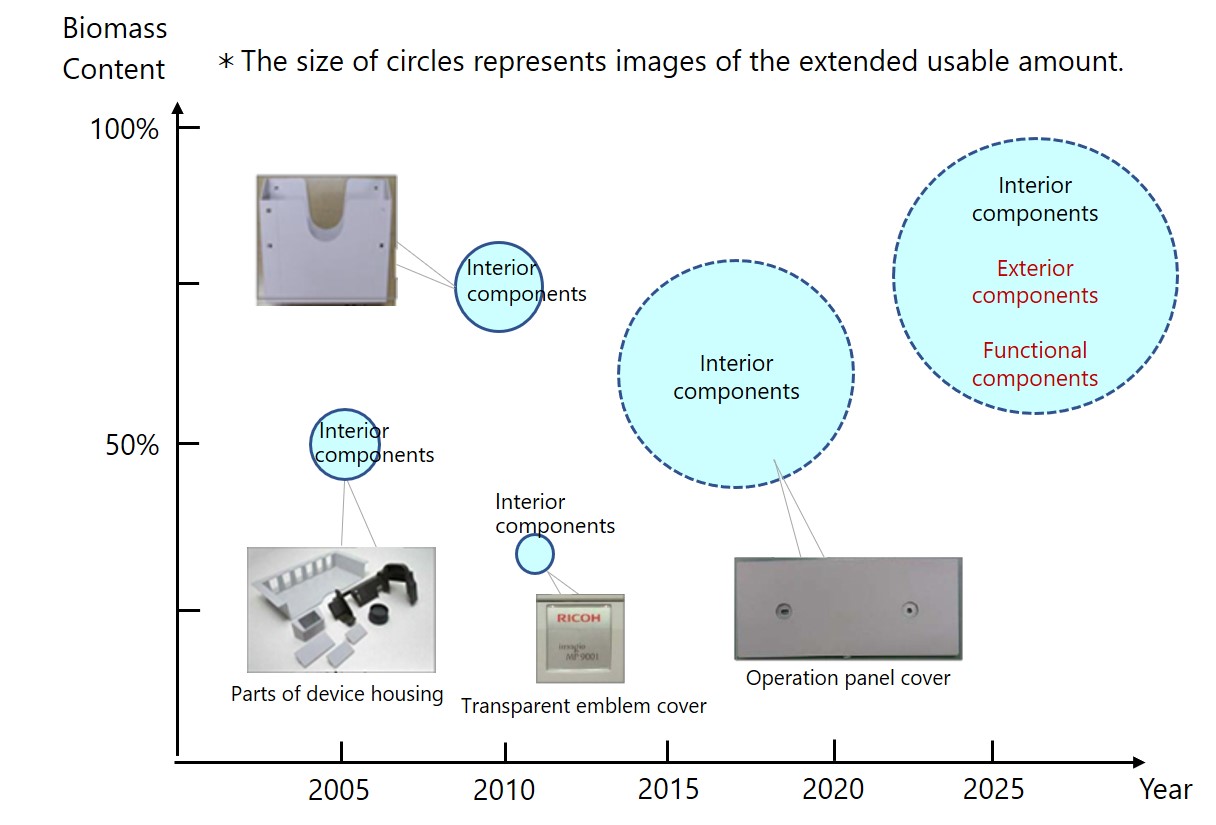

In 2002, we began developing biomass plastics with a 50% biomass content(*1) for multifunction copiers, which we applied to interior components for the first time in the industry in 2005. Ricoh made continuous efforts to increase the biomass content of materials, and in 2008, successfully introduced components that use materials consisting of nearly 70% biomass content.

Furthermore, Ricoh has been working towards the commercial application of highly-flame retardant biomass plastics that conform to the strict standards of strong fire redundancy and durability required for the exterior components of imaging devices to expand the use of such materials. In August 2013, we successfully introduced such biomass plastics to the exterior components of the production printer RICOH Pro 8100S/8110S/8120S.

(*1)The ratio of biomass plastics to the total used for components

Advantages and issues with the use of biomass plastics

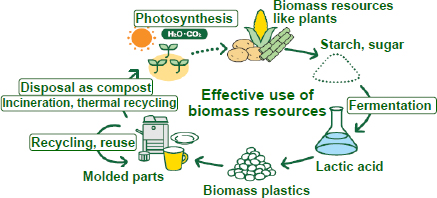

Biomass plastics utilize the biomass resources of regenerable biological origin. Currently, biomass plastics based on plant-derived materials are in practical use. The plastics are high-polymer materials made of raw materials consisting of starch, sugar, or cellulose contained in plants. One example is polylactic acid, the chemically-synthesized lactic acid that is fermented from starch. Even if polylactic acid is incinerated, the CO2 emitted is absorbed by the plants used as raw materials through photosynthesis during their growth. Therefore, it does not increase the CO2 in the atmosphere (carbon neutral). It is an environmentally-friendly material that does not contribute to global warming (Figure 1).

Furthermore, this material is as strong and rigid as polystyrene. However, there are issues with polylactic acid with durability, heat resistance, and impact resistance that need to be addressed; the materials used in parts for electric and electronic devices must be fire-retardant. In addition, there is the issue of mass-producibility when molding and processing into parts.

To solve these problems and achieve full-scale adoption in the future, Ricoh is also working on the development of material technology to apply polylactic acid to durable parts from inedible materials such as thinned wood and waste wood as molding technology with high mass productivity that is also economical.

|

| Figure 1: Circulation of biomass plastics |

Issues for expanding the use of biomass plastics and Ricoh’s approach

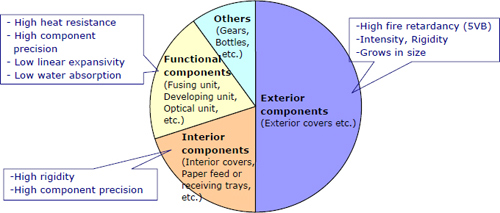

1. Issues for expanding the applications of biomass plastics to Multifunction Printers

|

| Figure 2: Proportion of plastics adopted for multifunction printers based on application and properties required |

2. Expanding biomass plastic applications

Ricoh has been using polylactic acid, a plant-derived crystalline polyester, as material in imaging devices. However, polylactic acid has issues with heat resistance, impact resistance, mass-production, and flame retardancy.

In the past, we handled this by blending petroleum-derived plastic with polylactic acid at specific ratios. Our imaging devices used such materials, including the RICOH MP 2555/3555/4055/5055/6055, RICOH SP 8400Ma1/8400a1/8400M/8400, RICOH IM 430F, and RICOH P 6000/6010/6020/6030.

Ricoh is currently developing new biomass plastics with higher biomass content, heat resistance, and impact resistance without mixing petroleum-based plastics.

3. Highly Flame Retardant Biomass Plastics

The required flame retardancy can be achieved by blending specific amounts of petroleum-derived plastics, but this is not an option for Ricoh. Instead, Ricoh has successfully enhanced biomass plastics’ flame retardancy and strength by developing technology jointly with a material supplier. The new biomass plastics feature improved formability, and the flame retardancy now meets the level V-1 standards. Durable, heat-resistant biomass plastics are now complete.

(*2)UL 94(the Standard of Underwriters Laboratories Inc.), the Standard of Safety for the Flammability of Plastic Materials of Parts in Devices and Appliances testing: the classifications are HB, V-2, V-1, V-0, 5VB, and 5VA (Underwriters Laboratories Inc., standard).

Ricoh’s philosophy of using biomass plastic in imaging devices

Going forward, to achieve Ricoh’s environmental target of a 60% or less virgin material usage rate (*3) in our products of FY2030, we will continue to improve rigidity and formability, which are requirements of materials used in larger components. In addition, heat resistance and water absorbency, while ensuring durable dimensional accuracy(*4), are essential properties of functional parts. Through such technological development, we aim to expand the use of biomass plastics (figure 6). In addition, we are working to enhance recycling activities to make a more significant environmental contribution to the biomass plastics lifecycle.

(*3) Virgin material usage rate is the usage rate of new resource inputs to total resource inputs of products. (*4) Durable dimensional accuracy: dimensional accuracy that needs to be ensured for multiple years without causing any dimensional changes due to heat/water absorption for the application to plastic components of imaging devices that will be used for more than five years.

|

Figure 6: Development image of biomass plastics |

Sorted by : field “Electrophotographic” “Resource Conservation” | product type “Environment”