- Home

- Technology

- Ricoh's Technology

- Biomass Toner Technology

Biomass Toner Technology

Biomass used as primary element of toner

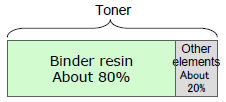

Every year, more than 200,000 tons of toner is produced worldwide. About 80% of that amount is resin. To lessen the environmental impacts of toner, Ricoh has been developing biomass toner(*1), for which we adopted plan-based resin.

Figure 1: Elements of toner

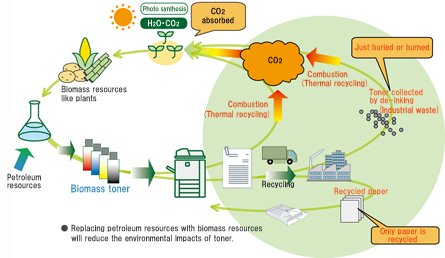

The biomass toner requires less petroleum than conventional toner, and contributes to the prevention of petroleum depletion. Being carbon-neutral, the biomass toner works to reduce the net amount of CO2 emitted from the combustion of used toner.

In November 2009, Ricoh released the world’s first digital multi-function copier featuring biomass toner, the “for E toner.” (This product is sold only in Japan.)

Click the image to view large one

Figure 2: Recycling biomass toner

(*1) Biomass resources are organic resources that are biologically reproducible, excluding fossil resources.

Low-temperature fixing and heat resistance?two contradictory features implemented

Toner must meet a variety of characteristic requirements. To reduce the power consumption of a copier, the power required for thermal fixing must be reduced. This, in turn, requires the toner to be molten at a low temperature. However, toner with a low melting point has its own problems?it tends to coagulate when stored under a high temperature, for instance. In this way, low-temperature fixing and heat resistance hinder each other. This dilemma can be solved depending on the characteristics of binder resin.

Plant-based resins have been widely used for molding, but their characteristics are far from those required for toner resins. Ricoh has thus developed a new plant-based resin for use as toner binders. It is already in use as part of the binder for our biomass-based “for E toner.”

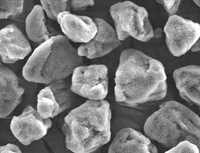

The biomass content of the “for E toner” is 25%(*2). While meeting the requirements of both low-temperature fixing and heat resistance, the “for E toner” has the same high performance as our petroleum-based toner. With the excellent chargeability and fluidity, the “for E toner” has even attained a higher image quality than conventional toner.

(*2) Ricoh uses the biomass content, in percentage, to indicate how much biomass is contained in parts.

Figure 3: The biomass “for E toner,” as used in a product

To steadily establish technologies and know-how

Ricoh has made an early start in using the biomass toner in actual products. Ricoh will continue accumulating technologies and know-how on the biomass toner in preparation for the full-scale operation in the future, intending to contribute to preserving the environment.

Sorted by : field “Electrophotographic” “Resource Conservation”