- Home

- Technology

- Ricoh's Technology

- Vibration Visualization for Machine Tools

Vibration Visualization for Machine Tools

Background

Process visualization has become a focus of attention in the manufacturing as it will serve many purposes including productivity improvement.

To visualize processes, you need to have an accurate grasp of the machining progress.

Much information for grasping machining progress can be obtained from machine vibrations.

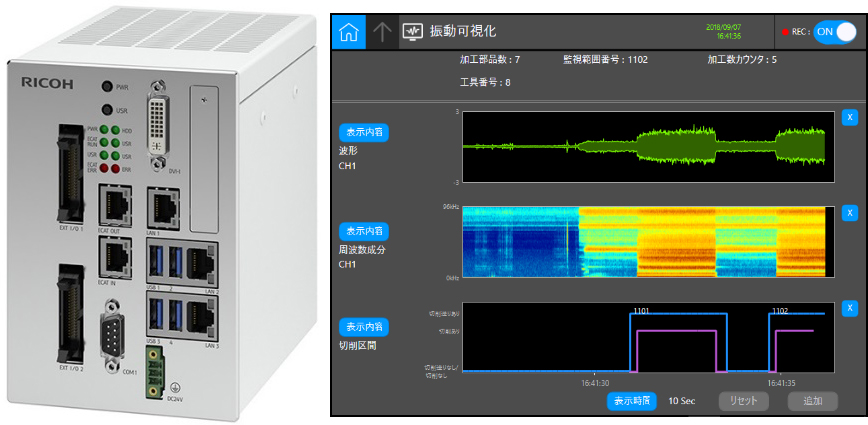

Ricoh's industrial PC, Sample system window

Ricoh's industrial PC, Sample system window

Solutions

Much information is contained in machine vibrations, accompanied by varied noise. To extract useful information only and grasp the progress accurately, three goals must be achieved:

- Accurate sensing of vibration under severe environments,

- Proper analysis of vibration that varies with the processing type and state, and

- Easy-to-see display of vibration features and judgment results.

Ricoh has achieved the three goals and successfully developed a real-time visualization system for machine tool vibrations. The system allows operators and supervisors to readily check the data to help improve productivity and quality.

Technical highlights

1. Highly durable devices

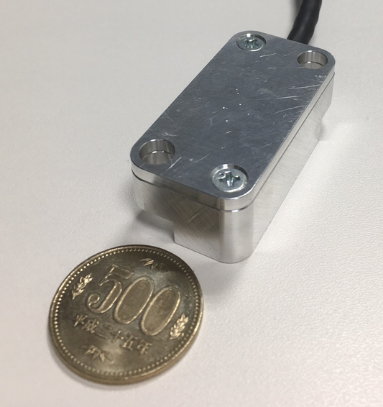

Many hazards exist in a machine tool: chips with sharp edges flying fast, coolants of various chemical properties, strong electromagnetic noise, and more. Ricoh has developed a special sensor that features resistance against shock, chemicals, and noise, and captures micro-vibrations in the audio and ultrasonic frequency ranges.

The special sensor features an acceleration pickup (a type of sensor that senses vibration and converts it into electrical signals) sealed in a sturdy aluminum casing. The pickup covers ultrasonic vibrations not audible to the human ear. The casing also contains an amplifier to reduce the influence of electromagnetic noise. The sensor cable has a moderate width, with a shock- and chemical-resistant jacket.

Special sensor

Special sensor

2. General-purpose analysis technology

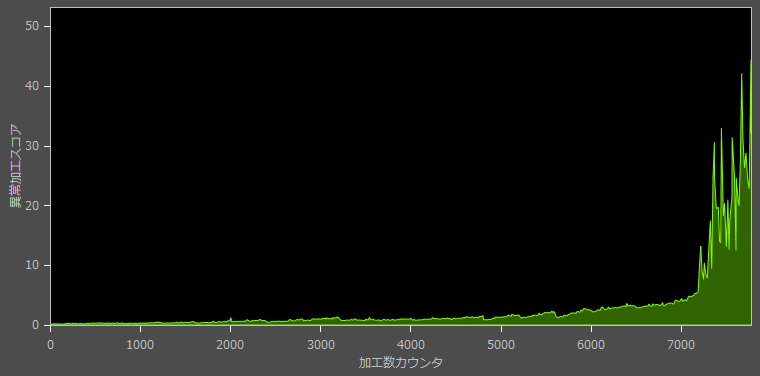

Vibrations of machine tools vary with the processing type, tool type, tool wear, material type, and more. Ricoh has developed an AI-based general-purpose algorithm that absorbs the influences of the variations and accurately digitizes machining quality and tool wear.

The algorithm consists of two steps: extraction of actual cutting periods and calculation of abnormal scores. The former is a preprocessing step; the periods where actual cutting by tool is taking place are extracted on the basis of the difference between the vibrations during and not during cutting. The latter digitizes the degree of abnormality on the basis of changes in the signals in the extracted actual cutting periods.

Abnormal scores

Abnormal scores

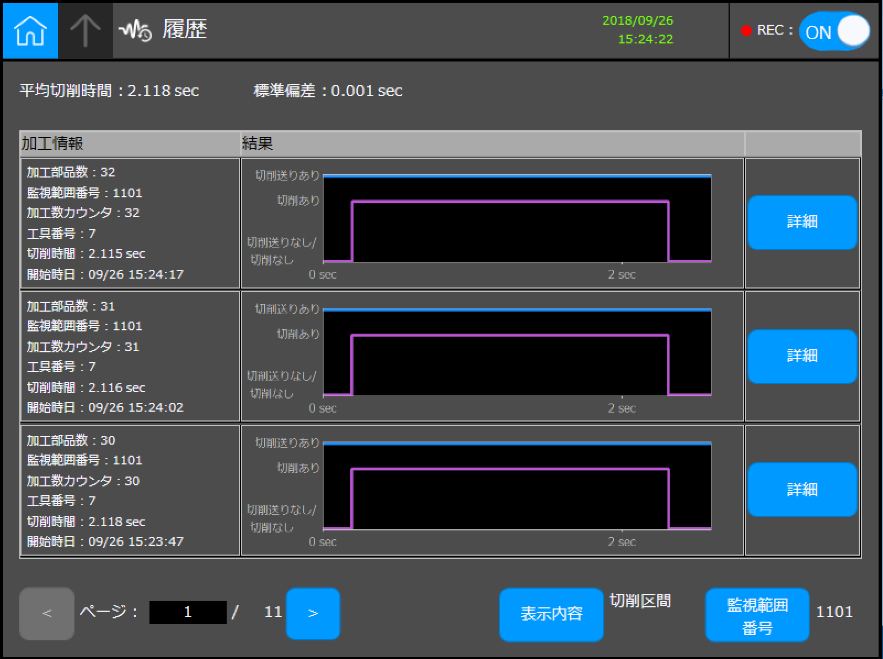

Results of the extraction of actual cutting periods are useful as they themselves suggest machining abnormalities*.

History of extracting actual cutting periods (pink lines)

History of extracting actual cutting periods (pink lines)

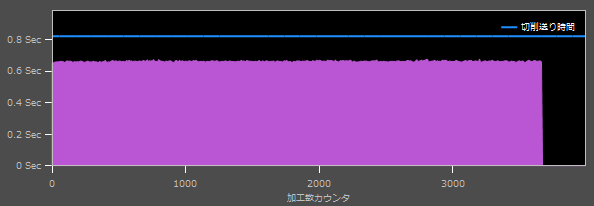

Lengths of extracted actual cutting periods (pink region)

Lengths of extracted actual cutting periods (pink region)

- *

- If lengths significantly fluctuate in the same processes repeated during mass production, it may indicate anomalies such as inappropriate tool attachment, tool damage, material supply error, and material shape error.

3. Highly operable, easy-to-see visualization interface

With this technology installed, the system is operable from an iHMI-spec CNC touch panel manufactured by FANUC. The operator-friendly interface allows easy operation on site. Button and indicator layouts have been carefully designed to maximize use of the limited screen space so that the operator can clearly see useful information, including amplitude and frequency elements of the vibration waveforms, scores obtained through analysis, and past records.

Ricoh's vision

The first product incorporating this technology has been developed in cooperation with FANUC as a module for FANUC ROBODRILL, a small machining robot. Ricoh will continue to develop technologies in pursuit of precision and ease of use, so that the value of this technology will be delivered to many more users, including those users of existing machine tools on the market.

Sorted by : field “AI (Artificial Intelligence)” “Sensing” | product type “Solutions”