- Home

- Ricoh's Technology

- A Novel Inkjet Printhead - Circulation in Individual Ink Chambers Prevents Ink Drying and Precipitation

A Novel Inkjet Printhead - Circulation in Individual Ink Chambers Prevents Ink Drying and Precipitation

Background

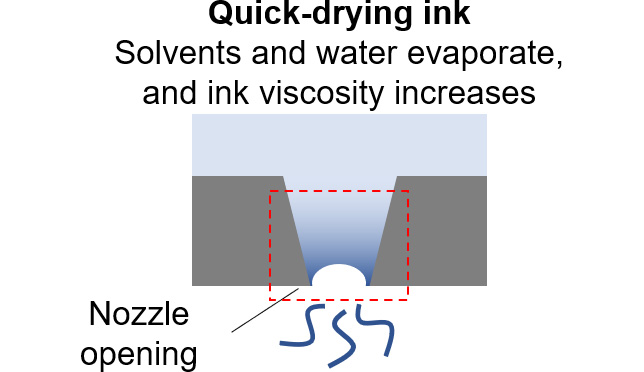

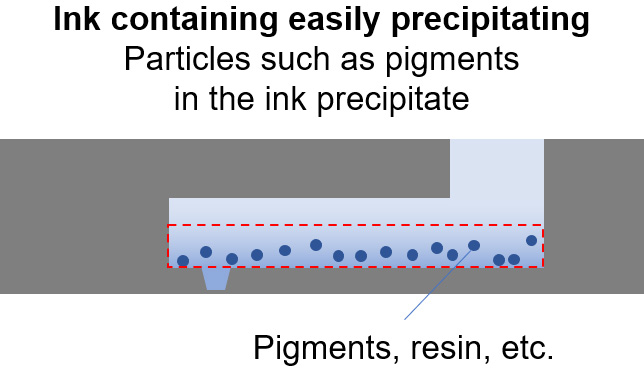

Inks deteriorate with time as their properties change. Once ink has deteriorated, an inkjet printhead cannot reliably discharge ink droplets. Typical deteriorations occur around the printhead nozzles due to drying and precipitation, which is problematic as inkjet printheads must periodically dispose of a certain amount of ink through the nozzles.

Yet demand is high for inks with special features, such as quick-drying inks and inks containing materials that easily precipitate. Accordingly, inkjet printheads must handle such specialty inks while delivering reliability. They are also required to waste less ink. Ink should be disposed as infrequently as possible to minimize waste and extend maintenance intervals.

Issues with inkjet printheads without circulation structure

Solutions

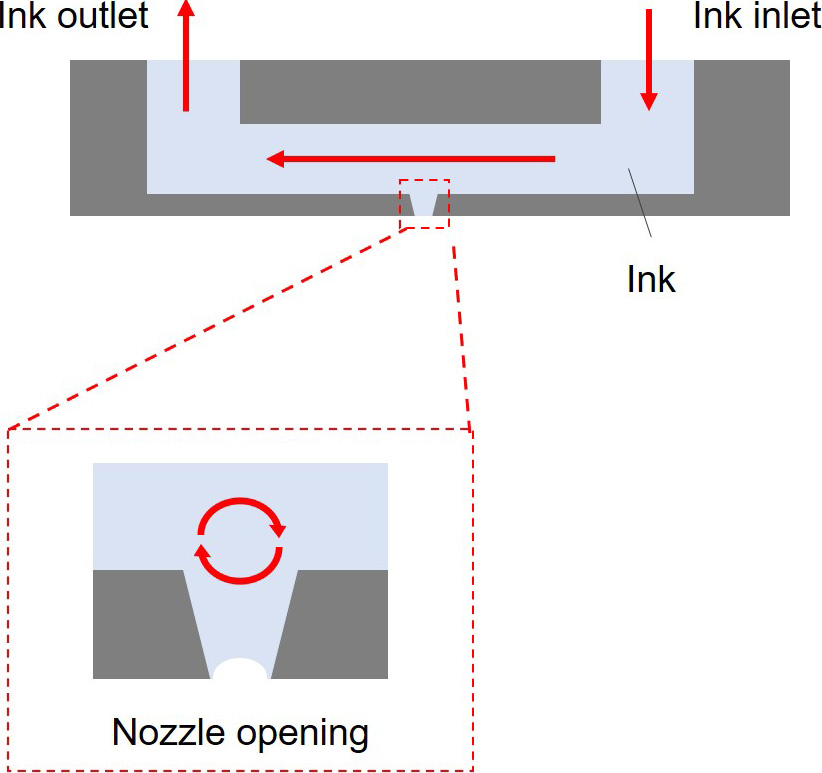

Ricoh's proprietary ink circulation structure enables constant ink circulation throughout the nozzles. This structure ensures high discharge reliability and makes ink disposal less frequent. Less ink wastage means a lighter environmental burden, while a lower maintenance frequency means a higher machine operating rate.

Inkjet printhead with circulation structure

Inkjet printhead with circulation structure

- High reliability in discharging specialty inks

Since the ink constantly flows around the nozzle, it does not easily dry around the nozzle opening. The constant ink flow inside the inkjet printhead suppresses the precipitation of high specific gravity particles. This structure ensures high stability in discharging quick-drying inks or inks that contain inorganic pigments, typically white and metallic pigments that easily precipitate.

- Low burden on the environment thanks to less ink wastage

Even with extended printer operation, the probability of drying and precipitation is so low that the printhead does not need to dispose of much ink. When the head is replenished with ink, the structure allows air to be ejected from the circulation path. Less ink will be disposed of through the nozzles during the replenishment process than before. The structure thus contributes to reducing environmental burdens.

- High machine operating rate

The structure helps lower the frequency of regular ink disposal and thus of maintenance work associated with it. Machines will have a longer operational period per unit time and operate more efficiently.

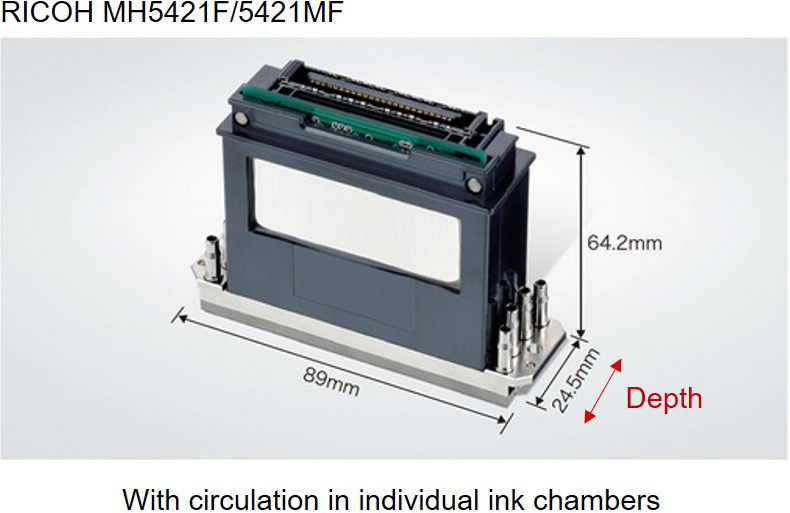

Technical highlights

The Ricoh circulation printheads are characterized by the 3D layout of the internal ink path, which keeps the printhead depth small. The RICOH MH5421F/5421MF printheads feature this design and are as small as the conventional RICOH MH5421 printhead, which does not have a circulation structure. This means that the RICOH MH5421F/5421MF printheads can be installed on a mounting surface designed for the RICOH MH5421 printhead.

Related information

Sorted by : field “Inkjet” | product type “Inkjet printheads”