- Home

- Technology

- Ricoh's Technology

- Flexible Energy Harvesting Device

Flexible Energy Harvesting Device

The “Internet of Things (IoT),” known as the fourth industrial revolution, is upon us. Today, many things are constantly connected to a network, such as sensors and wearables. A range of information is continuously accumulated and stored, and big data is utilized for social and economic activities. The trend is accelerated by the launch of 5G, the fifth-generation mobile communications standard, which has enabled ultrahigh-speed networks where large volumes of video and audio data are delivered instantly. The next-generation IoT society is just around the corner, ready to be implemented on a full scale.

Background of the flexible energy harvesting device

Energy supply is crucial to building an IoT society. There is rising demand for stand-alone power supplies adaptable to any living space by being compact and lightweight, requiring no routing or maintenance.

Eyes are on solar cells as stand-alone power supplies because they generate energy wherever there is light. Amorphous silicon solar cells*1 are known for their power generation performance even under weak light conditions, such as indoor lighting. Its power generation capacity, however, is insufficient.

Ricoh launched the world's first solid-state dye-sensitized solar cells , the RICOH EH DSSC series, in February 2020 and is now offering it as an independent electricity source required by IoT society. This stand-alone power supply can efficiently generate electricity from weak light sources such as indoor lighting. It can be used in a wide range of temperatures from -30°C to 60°C, making it suitable for indoor equipment.

The RICOH EH DSSC Series are employed in many products, including RICOH EH Environment Sensor D101, SMART R MOUSE, and the LOOPLINE T1 desk with built-in batteries. Their power generation performance under weak light has been well-received.

Customers interested in the RICOH EH DSSC series have asked for a thinner, lighter, and wider illumination range, which prompted us to develop further.

Solution

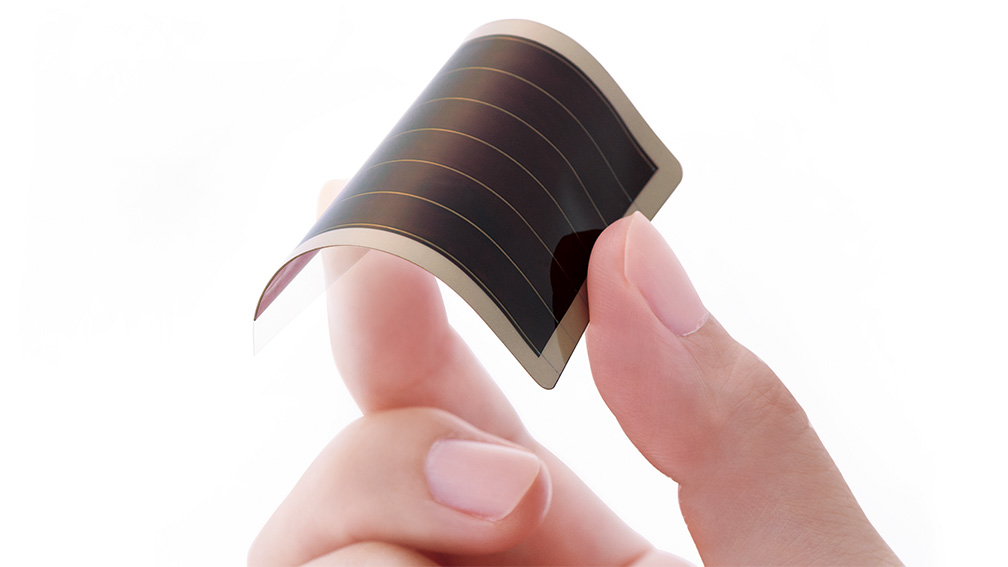

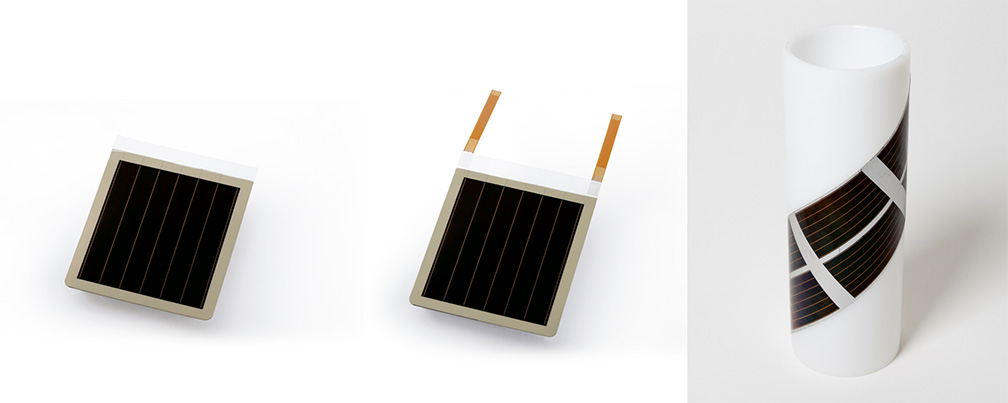

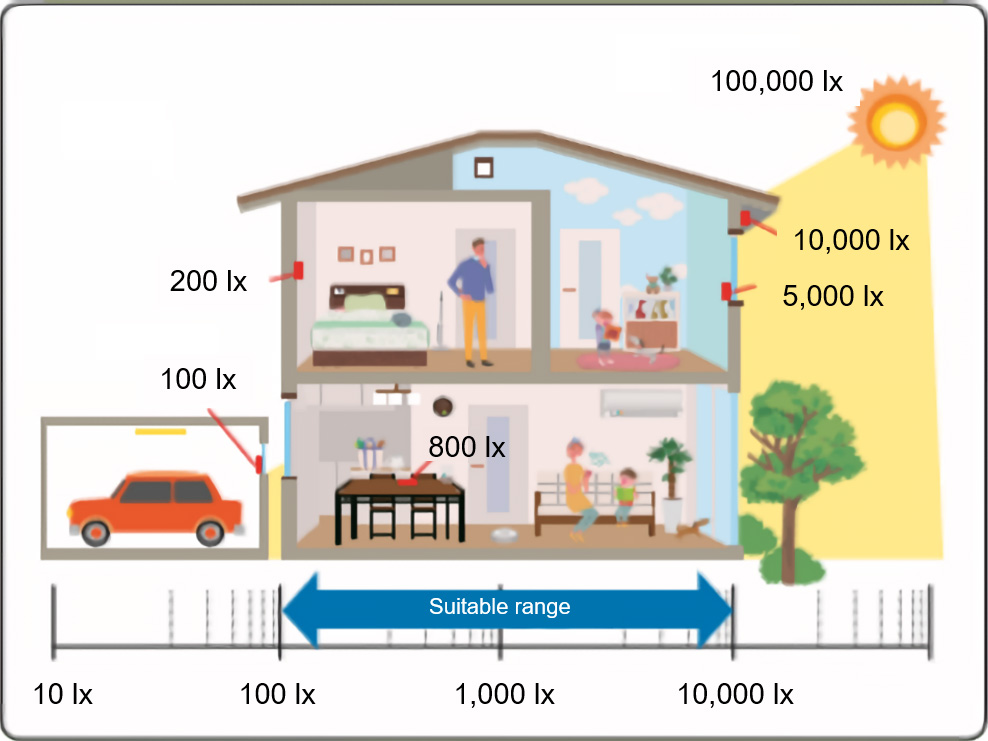

Ricoh has developed a next-generation solar cell that achieves high-power generation performance which comes as a flexible film that is hard to break thin, light and bendable. It efficiently generates electricity under weak light, ranging from indoor lightings to in bright areas near windows or outdoor shade.

Flexible energy harvesting device

Flexible energy harvesting device

The flexible energy harvesting device maintains high power output and high conversion efficiency under low light (200 lx) and medium (10,000 lx) illuminance conditions and has high durability. Its unique layered structure minimizes power drops due to partial shading. It is compatible with a broad range of operating environments.

Solar Cells Illuminance Range

Solar Cells Illuminance Range

| Illuminance | Maximum power (Pmax) min. | Maximum output voltage (VPmax) typ. | Maximum output current (IPmax) typ. |

|---|---|---|---|

| 200 lx | 84 µW | 3.3V | 25 µA |

| 10,000 lx | 4,200 µW | 3.6V | 1,200 µA |

- Maximum power (Pmax):

- Maximum power that can be taken out

- Maximum output voltage (VPmax):

- Voltage that maximizes power

- Maximum output current (IPmax):

- Current that maximizes power

Technical Highlights

Ricoh was quick to grasp the prospects of energy harvesting based on organic photoelectric conversion. In 2013, Ricoh formed a joint research team with Kyushu University to develop organic photovoltaic (OPV) thin-film solar cells. This industry-academia cooperation brought YASUDA Group, Kyushu University's advanced material technology and Ricoh's material and process technology nurtured through the development of organic photoconductor and solid-state dye-sensitized solar cells, the industry-academia cooperation has successfully demonstrated the world's highest photoelectric conversion efficiency (over 20%) under weak light like indoor illumination (LED, 2900K, 200 lx). (Arai & Yasuda et al., ACS Appl. Mater. Interfaces 2019, 11, 9259; J. Mater. Chem. A 2019, 7, 20187)

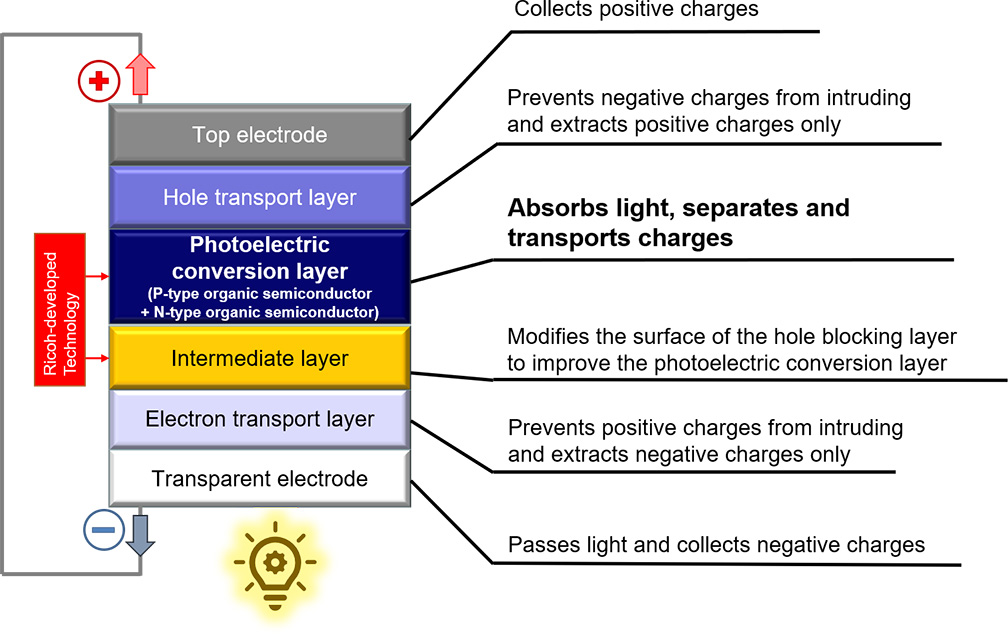

Structure of the flexible energy harvesting device

The flexible energy harvesting device is an organic photovoltaic thin-film solar cell. It has the stratified structure shown in the figure below.

Structure and functions of Ricoh's organic photovoltaic (OPV) thin-film solar cell

Structure and functions of Ricoh's organic photovoltaic (OPV) thin-film solar cell

Enhanced power generating efficiency and high durability

Ricoh has developed an organic photoelectric conversion system that produces high voltage and current under low to medium illuminance by precisely controlling the molecular structure and material composition of the photoelectric conversion layer (P-type organic semiconductor), through the joint development with Kyushu University.

The organic device has been designed and optimized to achieve high efficiency and durability; Ricoh's proven technology was used to produce the material of the intermediate layer (buffer layer) and control interfaces.

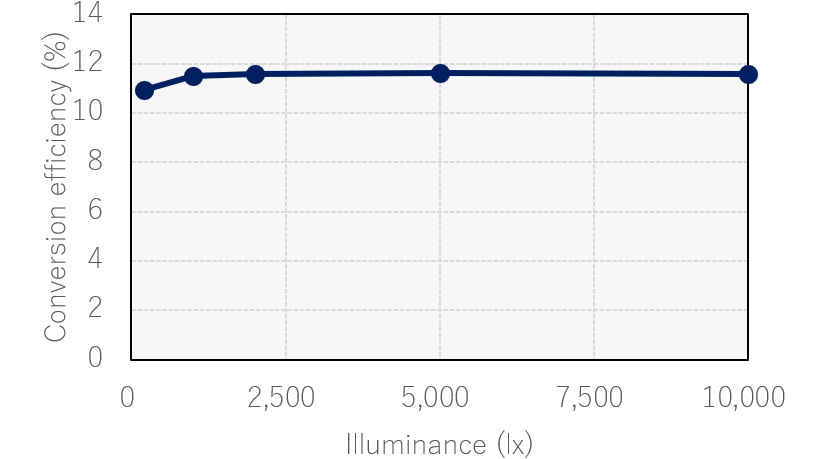

High conversion efficiency in a broad illuminance range

The device demonstrates a high photoelectric conversion efficiency under low (Approx. 200 lx) and medium (Approx. 10,000 lx) illuminance.

Illuminance dependency of conversion efficiency under LED 5000K

Illuminance dependency of conversion efficiency under LED 5000K

* Typical characteristics of conversion efficiency based on in-house evaluation.

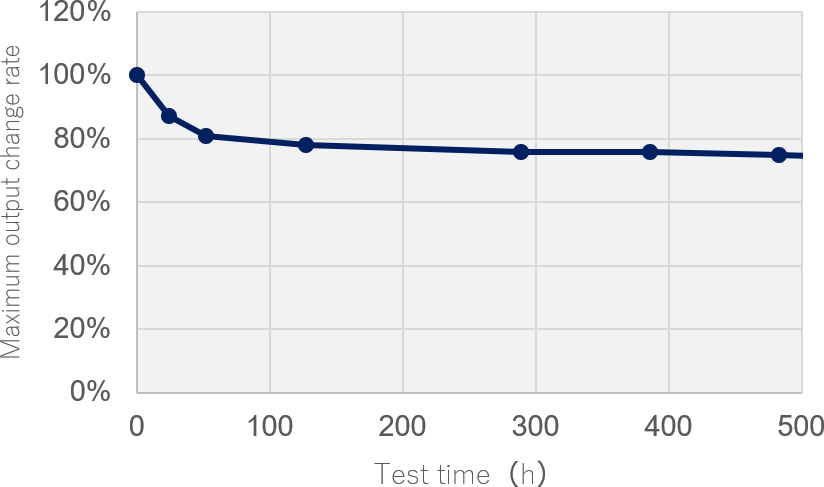

High durability under high illuminance

The device sustains a high output in a prolonged exposure test under high illuminance.

Simulated sunlight irradiation test (100,000 lx)

Simulated sunlight irradiation test (100,000 lx)

* Reference value of the device under development.

Ricoh's Vision

Ricoh strives to expand applications of the flexible energy harvesting device to sensors, terminals, and beacons. Its flexibility and lightweight are suitable for wearables and portable beacons. Its adaptability to a wide range of illuminance could be leveraged for sensors that monitor infrastructures such as roads and bridges and also for traceability sensors used in logistics and traffic analysis.

The technology has been adopted by a part of the A-STEP (Adaptable and Seamless Technology Transfer Program through Target-driven R&D) of Japan Science and Technology Agency since 2020. Ricoh will proceed with further development in the pursuit of further increasing efficiency and making the flexible energy harvesting device available to many applications in society.

- *1

- Amorphous silicon solar cell: A solar cell with a thin silicon amorphous layer of chemical vapor phase epitaxy of silane gas on the substrate. An amorphous silicon solar cell has about a 1.8 eV energy gap and absorbs and generates short-wavelength light of 700 nm or less. Amorphous silicon is mainly used for solar cells under natural indoor lighting because of its high output under weak light compared to crystalline silicon solar cells.

Contact information

- Energy Harvesting Strategy Department, RICOH Futures BU, Ricoh Company, Ltd.

- Inquiry Form

- zjp_dssc@jp.ricoh.com

Related Information

Sorted by : field “Energy Creation” “Materials”