- Home

- Ricoh's Technology

- Tunnel Monitoring System

Tunnel Monitoring System

As social infrastructure ages, its maintenance and management are becoming increasingly important. Consequently, they are expected to require more frequent inspections in the years to come.

Roads are an integral part of the social infrastructure. Keeping them safe as they age requires proper inspection of all essential elements—the road surfaces, tunnels, and roadside slopes. Ricoh has automated the inspection systems by combining its original optical systems with AI digital technologies, offering cost-effective, efficient inspection solutions.

Background

Japan has about 10,000 tunnels and safety management has become a critical social problem as the tunnels age. In 2014, the Ministry of Land, Infrastructure, and Transport issued new guidelines for periodic inspection of roads and tunnels. Accordingly, tunnels are being inspected throughout Japan for proper maintenance and management so that they can continue to serve as part of the nation’s infrastructure.

Conventional tunnel inspection methods require traffic flow to be stopped and special vehicles are required for high-lift work, with the individuals on board visually inspecting the surfaces. The task poses danger and is a significant workload. Some projects have started to use specially adapted vehicles, but this method is still costly.

Solutions

Ricoh has developed a photographing system mounted on a standard motor car. It measures the conditions of a tunnel while the vehicle is driving at normal traffic speeds. Other elements of the process such as work at the inspection site and the preparation of inspection reports are also automated. All result in making the tunnel inspection process efficient, safe, and secure.

Technical highlights

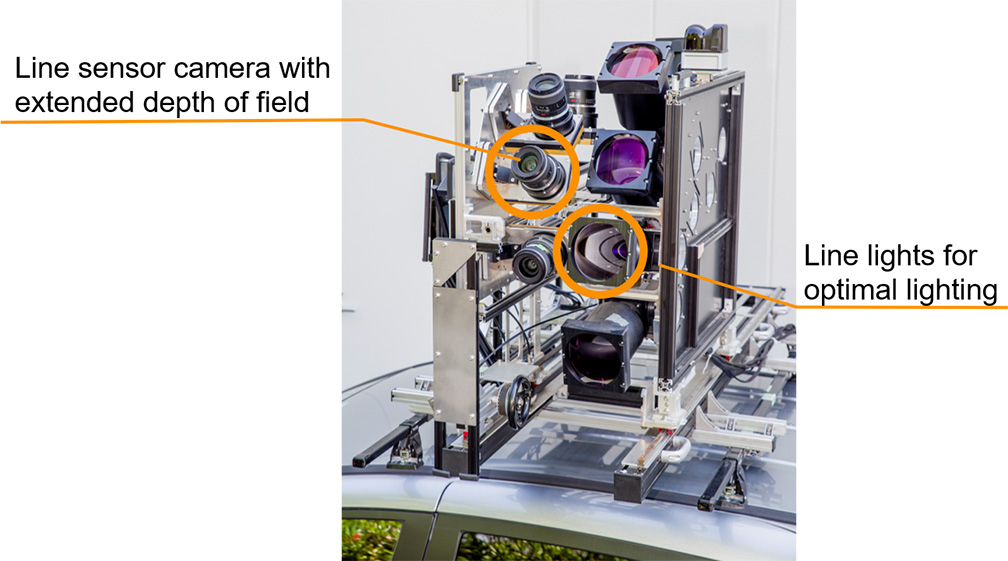

1. Line Sensor Cameras with Extended Depth of Field, Supported by Line Lights

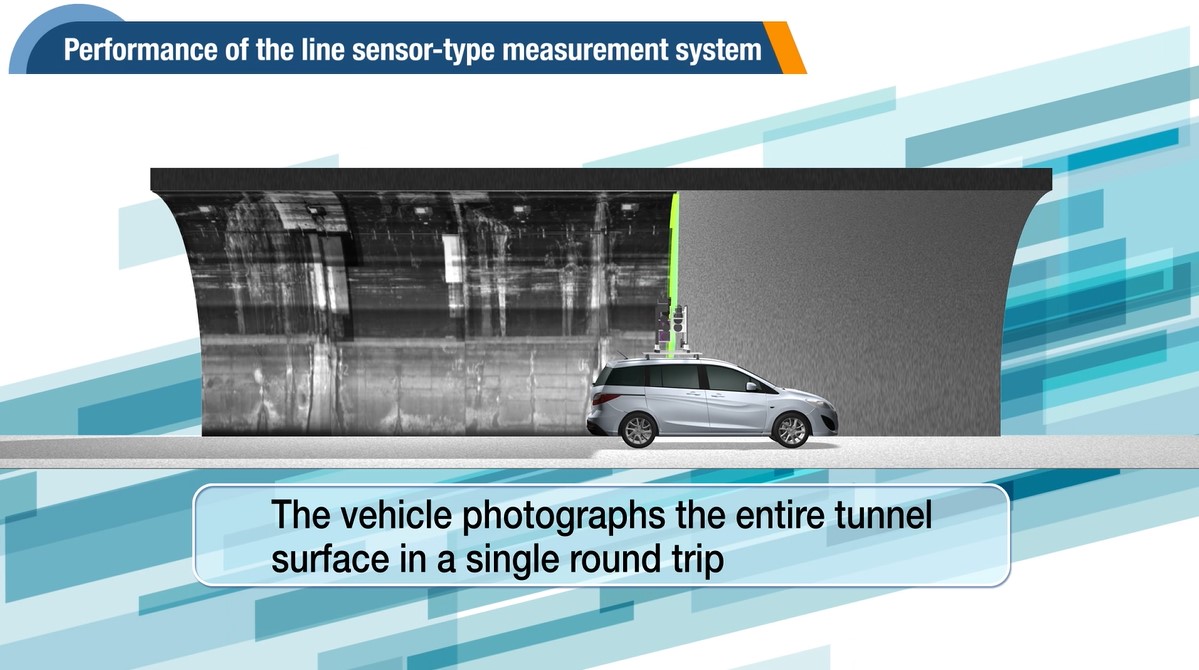

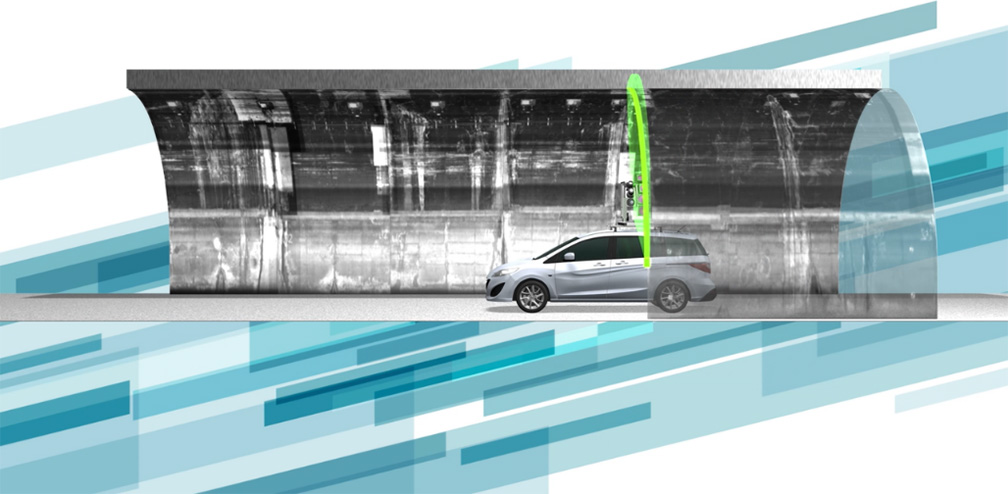

The photographing system features multiple line sensor cameras and line lights, designed to photograph the lined surfaces (walls) of a tunnel with an extended depth of field. The vehicle photographs the entire lined surfaces in a single round trip. This line sensor-type measurement system boasts high resolution and quality.

Performance of the line sensor-type measurement system

Performance of the line sensor-type measurement system

This line sensor measurement system is compact enough to be installed on a standard motor car and can easily be detached, making it easy to transport to other locations.

Line sensor-type measurement system

Line sensor-type measurement system

Originally developed by Ricoh, the multiple line sensor cameras feature an extended depth of field. The depth of field is the range of distances at which the photographed image stays in focus. These cameras have four- or five-times greater depth of field than a conventional camera and can capture clear images of lined surfaces in a dimly lit tunnel without sacrificing resolution or brightness.

The line lights are basically projector lights, but Ricoh had to shape the projector beam into a line by using its optical technology. The beam concentrated in a line optimally illuminates the tunnel wall.

These technologies allow tunnels to be inspected without stopping traffic. Field workers no longer have to be outside the vehicle to sketch, photograph or visually inspect the cracks and other anomalies. The technologies have both increased safety and reduced workload.

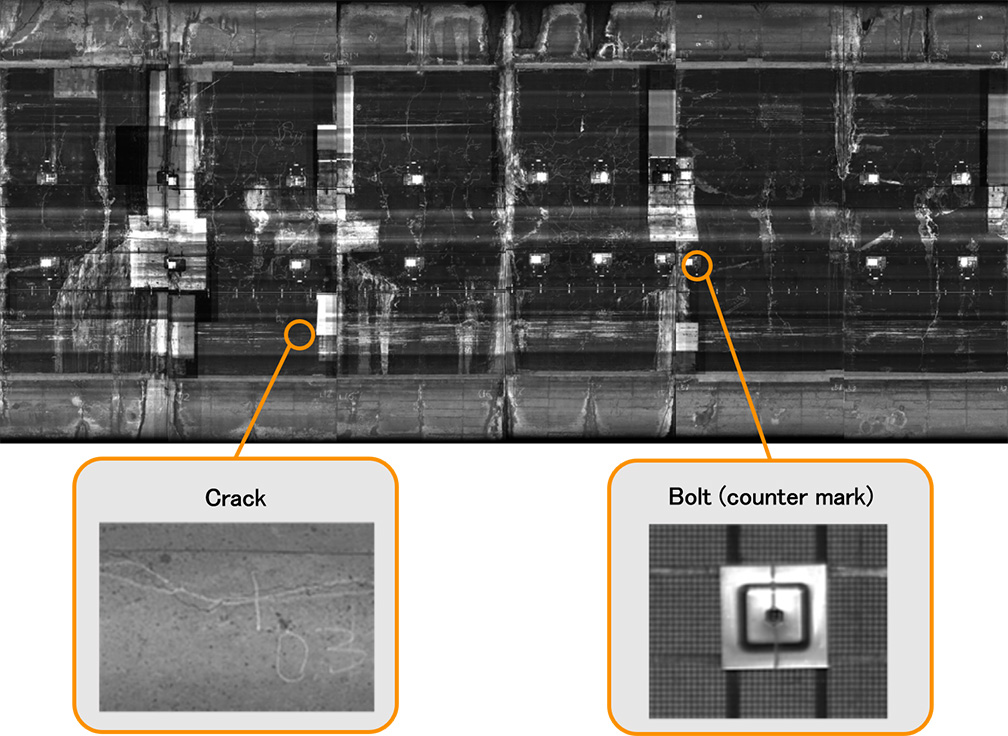

2. Expansion Images Automatically Generated

The photographed images are processed according to the shape of the lined surface. Precision expansion images are automatically generated. The expansion images make it possible to check the surfaces for cracks and loose bolts (counter marks). In addition, cracks can be automatically detected by the automatic crack detection function, which uses AI (Artificial Intelligence).

Expansion images reveal 0.3 mm cracks and bolt counter marks

Expansion images reveal 0.3 mm cracks and bolt counter marks

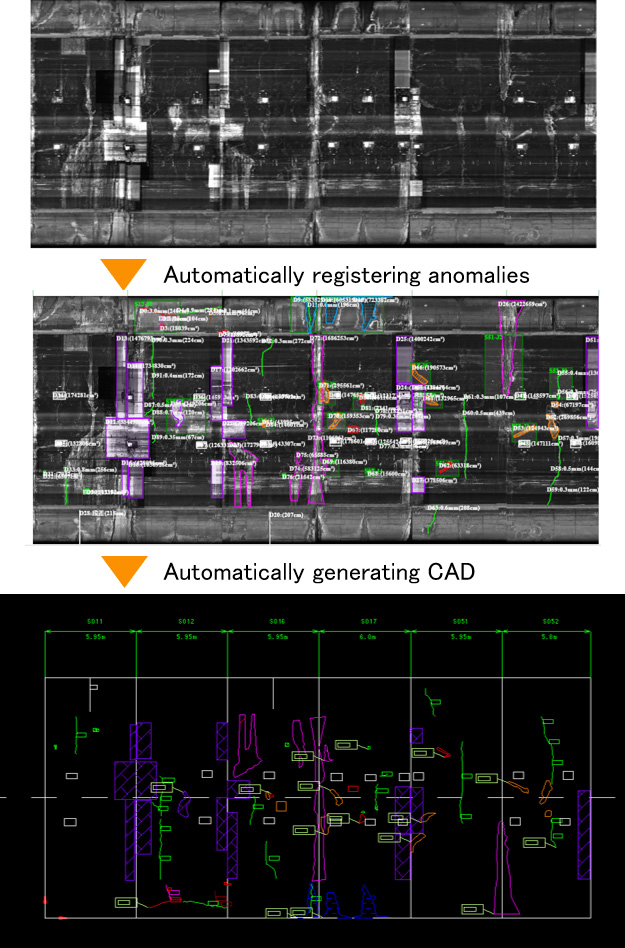

3. Visualizing the Results

Information on each anomaly can be registered on the expansion image. Inspection reports, including expansion anomaly drawings, photograph ledgers, and tunnel inspection summaries are automatically generated in the required format.

The workload of any subsequent inspections is also significantly reduced as the results can be compared with previous inspections.

Generating anomaly data from expansion images

Generating anomaly data from expansion images

Ricoh's vision

Ricoh develops technologies for the maintenance and management of infrastructure components, such as road pavements. The scope has expanded to tunnels. By developing infrastructure monitoring systems, Ricoh will continue to solve a range of social issues, including aging infrastructure and workforce shortage.