- Home

- Ricoh's Technology

- Color PxP-EQ Advanced Toner

Color PxP-EQ Advanced Toner

Achieving further energy saving through a toner with a lower fusion point

Most of the energy consumed by a multifunction printer constitutes the thermal energy used to fix the toner. The key to saving energy is to efficiently fix the toner at the lowest possible temperature. Ricoh has improved the energy-saving performance with its proprietary Color PxP (Polyester x Polymerization) Toner technology, which uses polyester resin that melts easily at low temperatures.

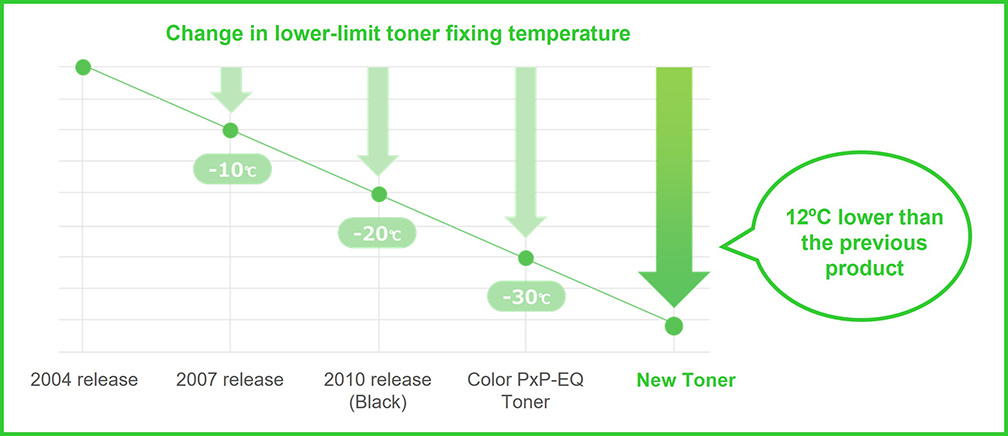

The Color PxP-EQ Advanced Toner used in the RICOH IM C2510/C3010/C3510/C4510/C5510/C6010 (released in February 2023) achieves a fusing temperature that is 12°C lower than that of the conventional color PxP-EQ toner, realizing the industry's lowest standard power consumption (TEC2018)*1 in A3 color multifunction printers*2 (Figure 1).

- *1:

- Figures are based on the measurement method defined by the International Energy Star Program.

- *2:

- The results of color QSU technology (DH fusing method) with improved thermal efficiency, as well as a smart position motor and a low-power-drive ASIC (integrated circuit). As confirmed by Ricoh in February 6, 2023.

Figure 1: Evolution of lowering the fusion point of the color PxP toner

Figure 1: Evolution of lowering the fusion point of the color PxP toner

Achieving both low fusion point and storage stability of toner

Generally, when toner is made with a lower fusion point, it melts more easily at lower temperatures, resulting in the deterioration of the toner's storage stability under high-temperature environments, such as during summer storage.

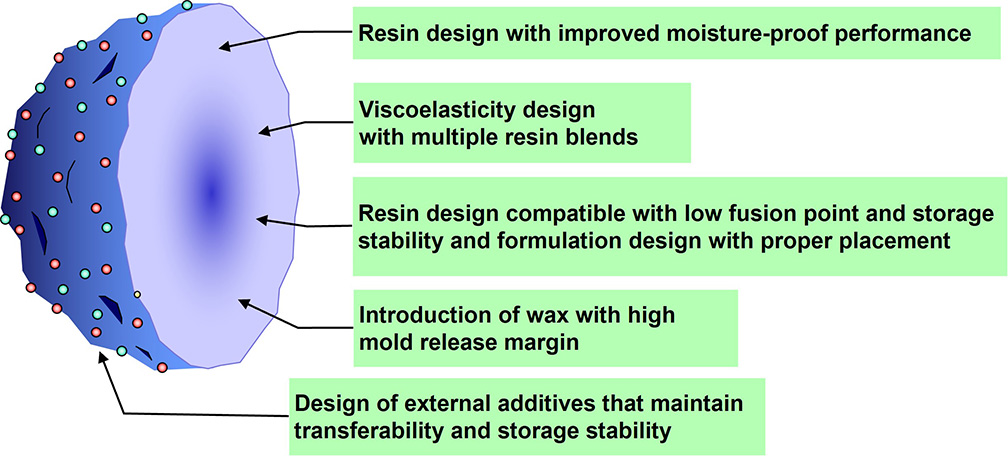

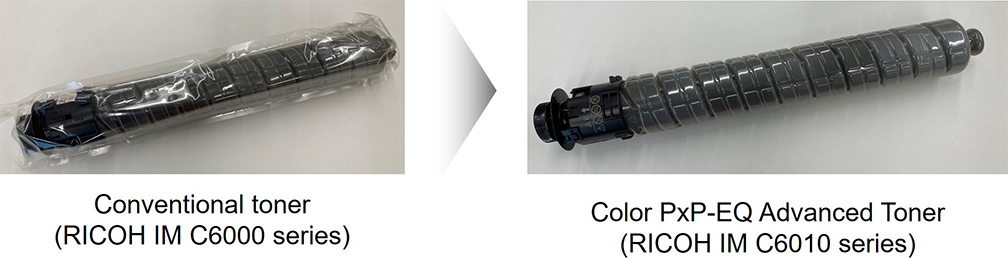

The Color PxP-EQ Advanced Toner is formulated with a resin that has a lower fusion point thus achieving a viscoelastic design which is superior to that of conventional toners in terms of fixability, while at the same time ensuring that the two resins—one with a low fusion point and the other with high storage stability—are properly arranged in the toner (Figure 2). As a result, it has both a low fusion point and high storage stability, achieving a fixing temperature that is 12°C lower than that of conventional toners. In addition, the resin design of the toner improves moisture resistance and reduces the amount of plastic used by eliminating the packaging bag (Figure 3).

Figure 2: Functions required of toner

Figure 2: Functions required of toner

Figure 3: Packaging of toner bottle

Figure 3: Packaging of toner bottle

Color PxP Toner Transition

Color PxP Toner since 2004

We developed the Color PxP Toner, a polymerized toner based on Ricoh's proprietary ester elongation polymerization method that uses polyester resin as the raw material, to address the need for a toner with excellent low-temperature fixing properties. Compared with the pulverized toner produced by the conventional method, the new toner features a smaller particle size and more uniform particle size distribution, achieving higher image quality and better low-temperature fixability.

Color PxP-EQ Toner since 2012

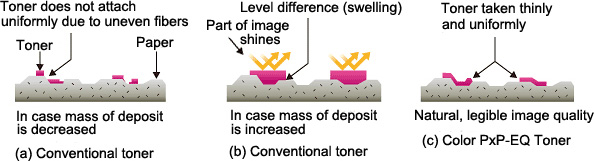

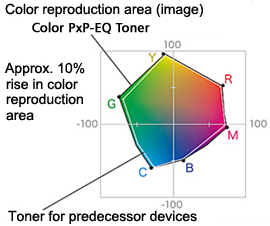

We developed the Color PxP-EQ Toner to feature the combination of Eco-friendliness (E) and Quality (Q) from the two aspects of energy saving (low-temperature fixing) and high image quality (color-gamut extension). Several new polyester resins were blended to achieve a low fusion point. At the same time, the toner's ductility (spreading ease) was improved and the color reproduction area was extended by 10% compared to conventional toners, enabling high-speed, high-quality printing on any type or thickness of paper (Figures 4 and 5). This technology is also used in the color PxP-EQ Advanced Toner.

Figure 4: Particle diameter and ductility of toner

Figure 4: Particle diameter and ductility of toner

Figure 5: Extension of color reproduction area

Figure 5: Extension of color reproduction area

Color PxP-EQR Toner since 2018

We developed the Color PxP-EQR Toner to maintain the color reproduction range of the Color PxP-EQ Toner while stabilizing image quality and improving reliability by improving the charging performance. The toner is used in production printers to enhance the stability of image quality during high-volume output.

Related information

- Environment

- Evolution of energy-saving technologies

Sorted by : field “Electrophotographic” “Energy Conservation” | product type “Ink / Toner”