Initiatives for realizing Zero-Carbon Society

Decarbonization in our business activities

Initiatives for Scope 1 and 2 emissions reduction

【Harness renewable energy】

Signing of VPPA and strengthening of adoption of renewable energy, with focus on supplementary potential

- Ricoh signed its first virtual power purchase agreement (VPPA) with KAMISATO KENSETSU, Inc. to promote the adoption of renewable energy. A VPPA provides a means for a user to virtually procure only the environmental value of renewable electricity generated from exclusive power plants built off-premise from the user. In Japan, it is a new form of renewable energy adoption that began in 2022.

- Since joining RE100 initiative, the Ricoh Group has worked to expand the use of renewable energy with supplementary potential through means such as on-site physical PPAs. Through the new VPPA, we aim to strengthen this supplementary potential to accelerate the adoption of renewable energy. The amount of renewable energy covered by the VPPA is about 2.15 GWh per year, and CO2 reduction effect is approx. 926 tons/year.

Ricoh's contracted power plant by Kamisato Construction, Iizuka City, Fukuoka Prefecture

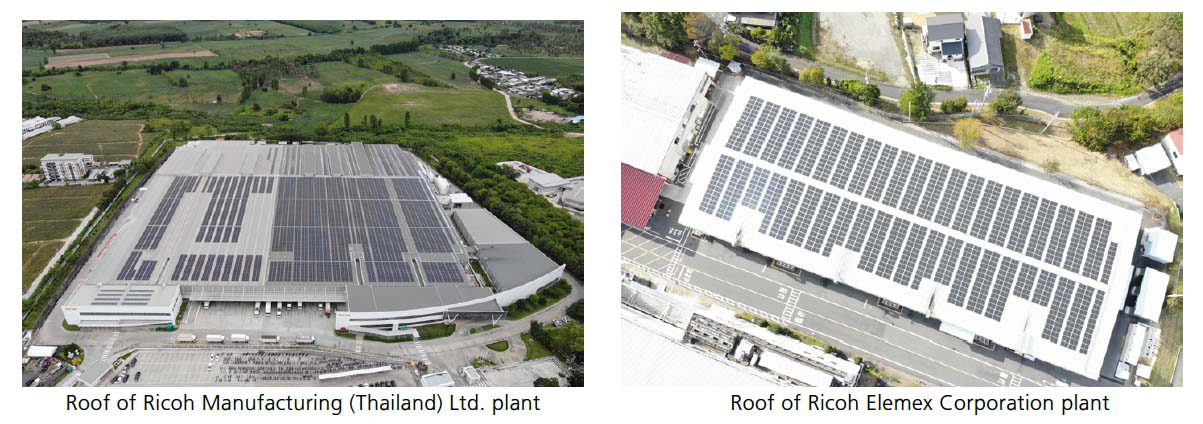

Promote implementation of on-site PPA* model at production sites

- In fiscal 2021, on-site PPA was introduced at Ricoh Manufacturing (Thailand) Ltd., Ricoh Elemex Corporation, and Ricoh Industries, Ltd.

- The total amount of electricity generated by five sites in total, including those already installed, was 8.54 GWh/year (CO2 reduction effect: approx. 4,417 tons/year)

- The cost reduction effect of Ricoh Manufacturing (Thailand) Ltd. was approximately 180 million yen over 12 years.

- RICOH ELEMEX, which started its operation in October 2021, is the first on-site PPA facility in Japan for the Ricoh Group.

* Abbreviation for Power Purchase Agreement: The on-site PPA model is a form of contract in which a power generation company installs power generation units on the site or roof of their customers, and the customer purchases the renewable electricity without purchasing the units.

Implementation of 100% renewable energy at A3 MFP (multifunction printer) production sites worldwide

- Since 2019, all power used for the assembly and production of A3 MFPs at all our global production sites (equivalent to 45 GWh) has been 100% renewable.

- Plants in China and Thailand are realized with the renewable energy certificate I-REC, and sites in Japan are recognized through Non-fossil certificate and renewable energy power menus.

Introduction of Comprehensive Evaluation System for Renewable Electricity

- In addition to its competitive price, we comprehensively evaluate the fact that it is an additional power source that promotes new development, that the environmental burden is lower, and that it is a power plant funded by the local community.

- At a site where it is decided to procure renewable electricity in Japan, we select an electricity supplier using this system. By utilizing this system, Ricoh has converted 100% of the electricity used at its Head Office (Ota-ku, Tokyo) to renewable electricity from fiscal 2021 (CO2 reduction effect: 2,000 tons/year; Renewable electricity: 4.3 GWh/year).

| Evaluation items | |

|---|---|

| Price | High score for cost effectiveness |

| Additionality | High score for newer power plants |

| Renewable energy type | High score for low environmental impact |

| Proximity | High score if power plant and purchasing office are close to each other |

| Power configuration | High score if the electricity itself is renewable energy |

| Evaluation of retail contractors | Points are awarded for the most recent CDP climate change score of A- or higher |

| Evaluation of power generators | Points are awarded for the most recent CDP climate change score of A- or higher |

| Local investment ratio | High score for high local investment ratio |

| Other local contributions | Qualitative evaluation of local donations, job creation, etc. |

Expansion of renewable energies usage at sites

- Ricoh Europe is promoting the use of offices where renewable energy is available. More than 90% of the electricity used in our offices, excluding factories, is powered by renewable energy.

- Ricoh Latin America HQ and thirteen sales companies have switched all of their electricity to renewable.

【Conserve energy and switch to alternative fuels 】

Reducing energy consumption based on the Act on Rationalizing Energy Use

In accordance with Act on Rationalizing Energy Use, business sites in Japan implement energy conservation measures with the goal of reducing the five-year average energy consumption intensity or the five-year average electricity demand optimization evaluation intensity by at least 1% per year.

- In 2024, Ricoh Japan Co., Ltd., Ricoh Industry Inc., and Ricoh Elemex Corporation achieved their targets and were certified as S Class (businesses with excellent energy conservation).

Installation of Waste Heat Recovery Heat Pumps at Production Sites

- In February 2022, waste heat recovery heat pumps were installed at the South Plant of the Numazu Plant.

- The waste heat being released into the atmosphere from the chiller/refrigerator cooling tower on the rooftop of Plant No. 8 in Numazu Plant will be used to generate hot water at 65°C, which is used in the dissolving process. By reducing the amount of steam consumption by approximately 60% (estimated value), both cost and CO2 emissions reduction (up to 540 tons/year) can be achieved. The ROI is approximately 5 years

- While promoting Scope 2 reductions by switching to renewable electricity, we are also tackling Scope 1 issues such as the use of steam, on which reductions are difficult to achieve

- In Japan, this initiative was recognized and won the

2023 Energy Conservation Grand Prize.

(Japan) News Release

Energy saving diagnosis

Ricoh Creative Services Co., Ltd., a subsidiary entrusted with the management of Ricoh business sites in Japan, systematically selects target business sites and conducts an Energy-saving diagnosis at each designated site in the order they are selected. In 2024, the diagnoses were conducted at two sites, creating sixteen energy saving measures (estimated reduction of 25 tCO2/year). At other sites, diagnoses on individual equipment were conducted, identifying 170 opportunities for improvements (estimated reduction of 278 tCO2/year).

- Energy saving diagnosis for production facilities proposes optimal operation of equipment according to the production environment, such as compressor setting pressure, and temperature and humidity control of processes.

- In addition to proposing the latest energy-saving equipment and technology, Ricoh Creative Services proposes improvements to the installation environment to fully utilize the capabilities of existing equipment, thereby reducing the amount of power consumed by the equipment.

Establishment of global standard for promoting sustainable real estate

In 2023, Ricoh Group Global Corporate Real Estate Policy set out the items that should be recommended for real

estate procurement with consideration for the environment, such as "use of renewable energy" and "buildings with

high environmental performance.“

We will continue to use the ISO 20400 framework as a guideline to study the visualization of the current situation

and promote the procurement of real estate with consideration for the environment.

Expansion of ZEB Office Buildings and Application to Business Proposals for Customers

- As of October 2025, a total of 19*1 sites have

acquired ZEB Ready certification or higher.

*1:18 sites of Ricoh Japan Co., Ltd., 1 site of ETRIA Co., Ltd. (Gotemba Plant) - Ricoh Japan intends to have all new office

buildings*2 be at least “ZEB Ready”. Each building will be a showcase for customers, introducing

visitors to the company's decarbonization practices.

*2:Owned by the company/Rented a whole building

(Japan) ZEB office buildings at Ricoh Japan

(Japan) ZEB office buildings at Ricoh Japan

ZEB Office Buildings

Miyazaki Office

Nearly ZEB office Buildings

Tsukuba Office

Expansion of Environment-friendly buildings

- Ricoh Latin America will be reinforcing the preferable use of LEED certification or equivalent environmentally friendly buildings for the new offices and warehouses. As an example, Ricoh Colombia and Costa Rica has already used the LEED certification offices.

Office of Ricoh Colombia

Initiatives for Scope3 emissions reduction

Strengthening of activities to promote the use of life cycle assessments (LCAs)

The Ricoh Group began using LCA in the 1990s, primarily for imaging products. Since the start of the EcoLeaf (currently SuMPO EPD) Type III environmental labeling program in 2002, we have also undertaken quantitative information disclosure on our products. Amid this current, we have placed staff in charge of promoting the use of LCAs in every business unit to strengthen the disclosure and appeal of our quantitative information.

Product Life-cycle Environmental Impact Assessment Technology

Product Life-cycle Environmental Impact Assessment Technology

Reduction measures in marine transport

- Adoption of eco-shipping using

biofuels

In fiscal 2022, we began contracting with the ECO Delivery service of Maersk. From January 2023 to December 2023, biofuel was used in the marine transport of 396.5 forty-foot containers. This reduced CO2 emissions by 3.51 tons for the extraction, refining, and transport of fuel and 831.9 tons for onboard fuel combustion, for a total reduction of 835.41 tons. - Improvement of container loading

rate

As a measure to control soaring marine freight fares caused by lack of space amid global turmoil in logistics, in fiscal 2022 we undertook activities to improve container loading efficiency. By making changes to packaging design and to mixes of parts, supplies, and products, and by eliminating containers with a loading rate of under 70% (primarily in marine transport bound for Europe and the United States), we reduced the number of containers by over 100, reduced CO2 emissions by about 2,000 tons, and achieved further cost reductions of about ¥200 million.

Energy saving and energy creation businesses

We are working to promote R&D activities and provide energy-saving products not only to our own decarbonization production process, but also to the decarbonization of society.

Environmental Technology Development

Ricoh promotes research and development activities by putting into practice the ideas and mechanisms for generating innovation in society and continuously developing environmental technologies that lead to decarbonization.

Environmental Technology

Environmental Technology

Development of decarbonization-contributing products

In order to deliver environmentally responsible products to our customers, we are actively acquiring environment labels both in and outside of Japan.

Environmental Labels

Environmental Labels

We are also promoting environmentally responsible production by operating the Ricoh Sustainable Products Program, which evaluates products based on our own strict standards for energy and resource savings, contamination prevention, user comfort, and ease of use.

Ricoh Sustainable Products Program,

Ricoh Sustainable Products Program,

- We have developed our products in accordance with the Ricoh Sustainable Products Program and they have acquired environmental labels. Consequently, we provide copiers/multifunction machines with outstanding energy-saving performance.

RICOH IM C7010

RICOH IM C7010

Energy saving and energy creation businesses

As the trend toward decarbonization accelerates, we offer decarbonization solutions to our customers in Japan in terms of “reducing”, “choosing”, “generating”, and “supplying” energy. We are promoting energy-saving and energy-creation related businesses, such as O&M (operation & maintenance) of customers’ solar power generation facilities, maintenance of EV charging facilities, and the lighting and air conditioning control systems, utilizing the monitoring services we have nurtured in the field of IT/networking equipment.

(Japan)Decarbonization solutions by Ricoh Japan

(Japan)Decarbonization solutions by Ricoh Japan