Initiatives for Effective Use of Water Resources

Use of gray water in collaboration with local companies

China/Shanghai Ricoh Digital Equipment Co., Ltd.

Shanghai Ricoh Digital Equipment Co., Ltd., an imaging products manufacturing subsidiary, uses gray water from a neighboring beverage company plant under a Shanghai Municipal People’s Government policy to conserve and protect water resources.

Shanghai Ricoh Digital Equipment uses this water in toilets, for watering and cleaning, refilling cooling towers, and for firefighting. This setup cuts water consumption and costs and complies with Shanghai’s water usage limits.

Promoting recycling of water by using rainwater

China/Ricoh Manufacturing (China) Ltd.

Ricoh Manufacturing (China) Ltd. (RMC), which manufactures office printing equipment, started production as an

environmentally friendly factory*1 in July 2020.

As one of these efforts, RMC installed an underground rainwater

collection tank with a capacity of 720m3 to store rainwater from July 2020 to conserve water resource.

By using the collected rainwater for flushing toilets and irrigating, RMC reduced the amount of water consumption.

RMC is also adopting solar power generation equipment, displacement ventilation and air conditioning systems, natural lighting and ventilation, etc., and is working to reduce CO2 as a factory that contributes to decarbonization.

*1 Acquired the design certification of the highest environmental certification in China [3-star green architecture]. Acquired LEED GOLD in the environmental performance evaluation system for buildings and urban environments developed by the non-profit organization U.S. Green Building Council (USGBC) and operated by Green Business Certification Inc. (GBCI)

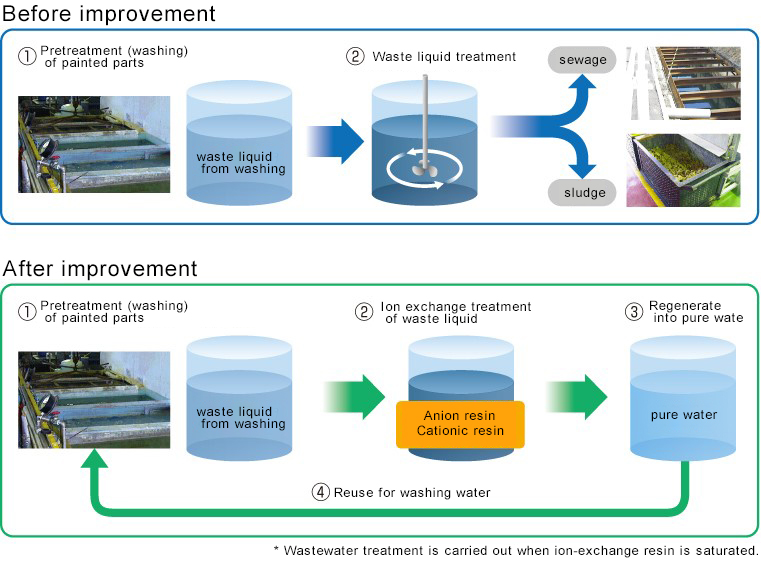

Closed system for surface treatment washing water

Japan/Hasama Ricoh

Ricoh designs and manufactures precision press parts and dies and recycles waste liquids from washing processes. We traditionally disposed all water from washing painted and precision press parts. In 1998, we adopted a closed system for all of these liquids, purifying wastewater through ion exchange treatment for reuse in washing. This setup has reduced our annual tap water consumption by around 60,000 cubic meters, cutting water bills and wastewater treatment costs.

Supplier engagement

Ricoh requires all suppliers to comply with the Ricoh Group Supplier Code of Conduct, which includes the article of water management. Based on this Code of Conduct, suppliers must document and monitor water sources, water usage and discharge, implement water conservation measures, and manage water pollution pathways. In fiscal 2021, 98% of our suppliers signed off on the Code of Conduct.

We also request our major suppliers to answer self-assessment questionnaires that evaluates the status of their efforts to address CSR issues, including water resource issues. We have been conducting this CSR self-assessment every year since fiscal 2018, and we are able to ascertain the status of our suppliers' initiatives through confirming whether they have targets for greenhouse gas emission reduction and water resource reduction. If they have no reduction targets, Ricoh explains the importance of water management to the suppliers and encourages them to set targets. Besides, we conduct improvement activities for suppliers diagnosed as "high risk suppliers" as a result of the assessment. We continue to engage with our suppliers to effectively utilize water resources throughout the value chain.