Initiatives for End of Life Products

Reuse and Recycling Program and Network

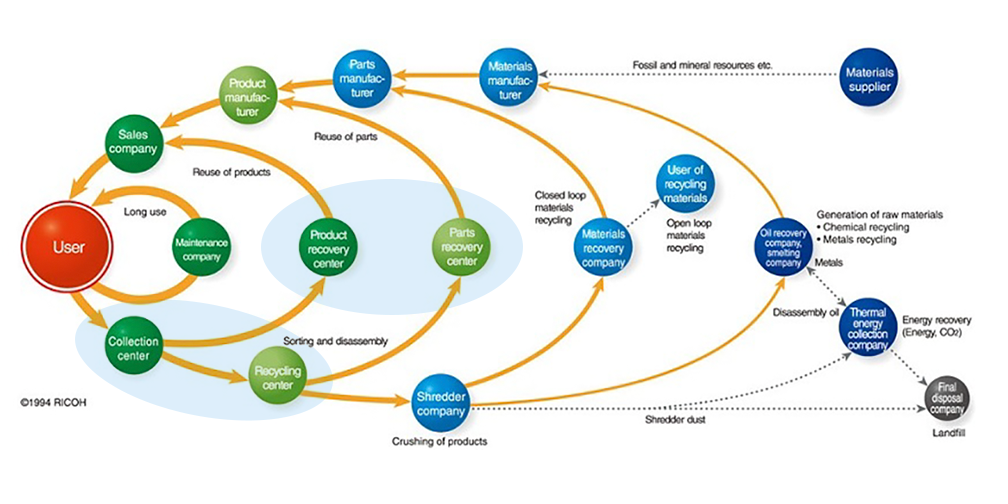

Main areas of activity of this initiative is highlighted on the Comet Circle.

Main partners.

‐Collection center

‐Recycling center

‐Product recovery center

‐Parts recovery center

1. Program

The Ricoh Group has practiced resource conservation and recycling as one of the pillars of its environmental conservation activities since the early 1990s and has been developing global reuse and recycling initiatives for MFPs, printers, supplies, and consumable parts collected from customers by region and by product. In treating end-of-life products, the Ricoh Group offers electrical and electronic waste programs in accordance with the waste-related laws and regulations of each country (such as the European WEEE Directive) and strives to recycle them within each country. Furthermore, in accordance with the Basel Ban Amendment to the Basel Convention, the Ricoh Group bans the export of electrical and electronic waste from OECD member countries to non-OECD member countries for disposal and recovery, and confirms that no such exports have taken place. We will continue to maintain compliance with the Basel Ban Amendment to the Basel Convention.

In Japan, we apply a lease-based business model for MFPs in which we maintain a framework to track each unit, with our collection system tapping into it. We leverage the accumulated expertise from this setup in countries with varying business models. The Ricoh Group collects more than 300,000 end-of-life in-house products annually from around the world. Of these, approximately 50,000 are sold as reused or remanufactured products. We reuse parts or recycle materials from products that cannot be reused or recycled. Since 2010, our product design and technology divisions have helped us reuse functional components in periodically replaced units for imaging products. We will continue to make progress with initiatives internally and with suppliers and other business partners to broaden the scope of reuse and recycling.

Regional program

Regional program

The Ricoh Group has a programme for e-waste that complies with the laws and regulations of each country.

North Americas

In the US, we have implemented a recycling system for products and consumables. In some of the states, by utilizing

In Canada, Ricoh Canada operates a recycling program for Ricoh products available for sale as well as US.

Asia Pacific

In Singapore, small printers are eligible for the Singapore Government's collection program

In China, parts and consumables can be brought in by customers* themselves, using the communication app WeChat to obtain contact information for collection points (*conditions apply for service use). Customers can also return them by post (free of charge).

EMEA

In Europe, we have

Japan

In Japan, we have

Programs by product

(Japan) Recycling Program of used products and printer cartridges (Japanese)

(Japan) Recycling Program of used products and printer cartridges (Japanese)

(US) Product Stewardship and Recycling

(US) Product Stewardship and Recycling

(US) Take Back Program

(US) Take Back Program

(Europe) Resource Return Program

(Europe) Resource Return Program

2. Network(Global takeback programs, reuse, and recycling)

We deploy takeback programs, reuse, and recycling efforts through our own facilities in Europe, Japan, Americas, Asia, and China business regions. Each Group company maintains standards for selecting trustworthy industrial waste contractors.

These standards include such internationally recognized endorsements as ISO 14001, ISO 9001, R2, and e-Stewards.

Case Study in Japan (Japanese)

Case Study in China

Case Study in Europe

3. Network utilization

Takeback for supply and parts

(Japan)

To promote recycling, we have introduced a collection and recycling system for replaced parts that occur during maintenance services. This system does not dispatch vehicles for parts collection, but loads parts collected from service bases all over Japan on the return line after parts delivery operated by SBS Ricoh Logistics and transports them to the recycling base operated by Ricoh.

(Europe)

Since 2012, Ricoh (in Europe) has added and strengthened a new collection scheme to increase collection of used supplies. Ricoh (in Europe) purchases Ricoh's supplies collected by 3rd party companies. As of Dec 2023, we are now working with 15 collection companies in 8 Countries across Europe, and plan to expand this network further. Through this effort, we will increase the amounts of supplies collection and promote our reuse and recycling.

Takeback by MFP industry Network

(Japan)

Ricoh participates in the recovered equipment exchange system run by the Japan Business Machine and Information System Industries Association (JBMIA).

Through this initiative, equipment turned in by manufacturers of copiers, MFPs and digital printers, including Ricoh, are collected at shared collection centers and returned to manufacturers, thus promoting the reuse and recycling of products in the industry overall.

There are 35 collection sites and nine exchange centers for collected machines from Hokkaido to Okinawa, covering all of Japan.

JBMIA initiatives (Collection system) (Japanese)

JBMIA initiatives (Collection system) (Japanese)

JBMIA initiatives (Sharing recycling facilities) (Japanese)

JBMIA initiatives (Sharing recycling facilities) (Japanese)

(Europe)

In France, 17 office equipment manufacturers including Ricoh France jointly invested to establish CONIBI and contracted recovery operations to this joint company. CONIBI has created its own free collection system and promotes the recycling of toner cartridges and consumables.

Recyclage toner en entreprise

Recyclage toner en entreprise

Waste Management Programs

1. Waste audits to identify opportunities for improving waste performance

As part of the Ricoh Group’s efforts to reduce environmental impact and realize a circular economy, the company conducts regular waste audits. These audits aim to identify and analyze the types and quantities of waste generated through business operations, thereby pinpointing areas with high waste generation. The findings are used to reduce waste volume, improve recycling rates, enhance the quality of recycling methods, and contribute to better energy performance.

The audits involve reviewing waste management records, conducting on-site inspections, and interviewing relevant departments. These activities support the promotion of resource recovery, proper waste treatment, and improved energy efficiency.

Ricoh will continue to conduct regular audits and pursue continuous improvement to minimize environmental impact and promote the efficient use of resources.

2. Action plans to reduce waste generation

The Ricoh Group identifies business units with high levels of waste generation and prioritizes initiatives aimed at reducing waste in those areas.

The selection of these priority units is based on the results of regularly conducted waste performance assessments and audits.

In addition, the designated priority units and the ESG Promotion Division hold regular progress review meetings and work collaboratively to suppress waste generation and promote resource recovery.

3. Quantified targets to minimize waste

The Ricoh Group establishes specific and measurable quantitative targets for waste management with the aim of continuously improving performance.

For fiscal year 2025, the company has set a target to keep total waste emissions below the previous year's actual performance, with the target volume set at 53,835 tons.

4. Investment in innovation or R&D to minimize waste

Ricoh Group actively allocates investments and human resources to research and development (R&D) and innovation activities to minimize waste generated through its business operations.

The Company is engaged in the development of technologies such as those contributing to yield improvement in production processes, those enabling reuse of by-products, and those for the closed-loop recycling of solvents. These efforts contribute to reducing waste and enhancing recycling technologies.

Through these initiatives, Ricoh aims to mitigate environmental impact, promote the circular use of resources, and contribute to the realization of a more sustainable society.

Example: Reuse of resources through closed solvent reusing in the PxP toner (polymerized toner) production process

Ricoh’s Numazu Plant and the Tohoku Plant of Ricoh industry conduct closed recycling of solvents used in the production of PxP toner. Solvents used in part of the production process have been material recycled by subcontractors, but with the aim of recycling and reusing this solvent in our own processes, we have been working on improving material design of toner and production technology. It was difficult to reproduce conventional mixed solvents containing multiple chemicals, but as a result of research, we succeeded in developing production technology using a single solvent instead of mixed solvents. Through this, except for the cleaning solvent generated when switching products, it is possible to reuse the solvent used in production. This not only makes it possible to reduce waste solvents, but we were also able to slash new solvent inputs by about 90%, and we were also able to achieve significant costs reductions. Furthermore, by establishing a process for resolvating waste solvents that had been outsourced, we are now able to cover most of the solvents used in normal production with reused solvents.

Facilities that conduct reusing of solvents (distillation facilities)

5. Integration of recycling programs to reduce the waste sent to landfill/Waste diversion from landfill is certified by an independent accredited body

The Ricoh Group regularly evaluates the recycling performance of waste generated at each business site with the aim of reducing landfill disposal and promoting resource recovery.

Recycling rate targets are set for each site based on internal standards, taking into account the nature of their operations.

The achievement status of these targets is reviewed periodically, and in cases where targets are not met, corrective measures are implemented. These include efforts to reduce the generation of non-recyclable waste and reconsideration of waste contractors to avoid landfill or simple incineration.

Through these efforts, Ricoh integrates effective recycling programs across the Company and maximizes material reuse.

The Ricoh Group regards reducing environmental impact as a critical responsibility and is committed to achieving “zero landfill” of waste generated through its business activities.

The Ricoh Group’s waste management policy extends beyond simple recycling to encompass waste diversion strategies, including reduction, reuse, composting, and utilization as renewable energy. The company’s guiding principle is to prioritize low-impact reuse and recycling practices while minimizing energy recovery through incineration.

Furthermore, Ricoh proactively addresses waste reduction at the source through design-stage prevention and operational process improvements.

To ensure data transparency and reliability, Ricoh obtains independent third-party verification of its waste data.

Third-Party Verification Results

Third-Party Verification Results

For fiscal year 2024, the diversion rate was 99.7%.

Diversion Rate (%) = (Amount Diverted ÷ (Amount Diverted + Landfilled Amount)) × 100

Reuse and Recycling Businesses

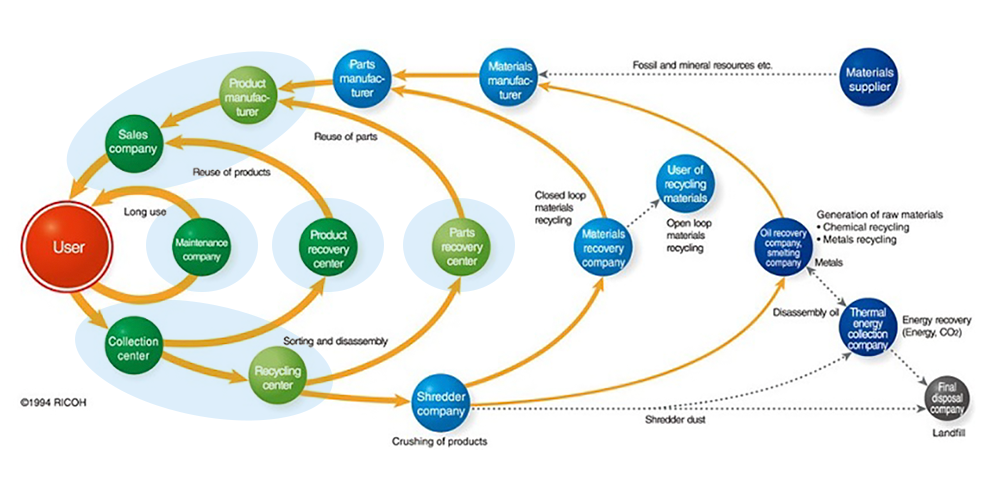

Main areas of activity of this initiative is highlighted on the Comet Circle.

Main partners.

‐Product manufacturer

‐Maintenance company

‐Product recovery center

‐Parts recovery center

‐Collection center

‐Recycling center

We have done much since the 1990s to cultivate our product refurbishment and reuse and recycling businesses, necessitating a range of efforts to make them viable. We have acquired many technologies and expertise over the years to commercialize product and parts remanufacturing. Sales of that business reached around 30 billion yen in fiscal 2022

Key Commercialization Initiatives

1.Manufacturing Based on Design Policy for End of Life

The most important thing for product remanufacturing is to incorporate the perspectives of reuse, recycling, and long-term use into the product design concept in advance. We established what we now call the Design Policy for End of Life in 1993. The policy encompasses design standards for common parts and materials to streamline the reuse and recycling of recovered products and parts and to reduce degradability. For more than 20 years, we have made prospective reuse and recycling central to product design.

2. Optimized Takeback, Remanufacturing and Recycling Sites

We reuse and recycle products, supplies, and parts that in our facilities in Europe, Japan, the Americas, Asia, and China regions collect from customers. The first step in remanufacturing products is to efficiently and reliably collect used products from markets. We set up 22 collection sites across Japan to streamline collections. We centralized remanufacturing at the Ricoh Eco Business Development Center in Gotemba to enhance efficiency. We have endeavored over the years to optimally locate sites and establish our current structure. One strength of our remanufacturing business is that this center engages in both remanufacturing and recycling. Necessary parts that we remove from used products that are impossible to remanufacture can become service or replacement parts for remanufactured products. We maintain a system to sell non-reusable parts as valuable recycling materials, minimizing costs by eliminating expenses and labor by shipping them to recyclers.

3. Reuse and Recycling Technologies to Optimize Quality, Cost, and Delivery

We established evaluation, diagnostics, disassembly, cleaning, washing, restoration, erasure, and recycling technologies to optimize quality, cost, and delivery in our remanufacturing business. Evaluation and diagnostics technologies are pivotal for generating earnings. Evaluation technology determines the reusability of used products based on assessments of their residual usability and other factors. It enables us to cut transportation costs by shipping only products that can be remanufactured from collection sites across Japan to the Ricoh Eco Business Development Center. Diagnostic technology assesses the conditions of prospectively reusable products. We categorize products in different conditions, putting them on reclamation lines by level to streamline production.

4. Collected Machine Management System Ensures Reliable Production and Sales Planning (Japan)

Product commercialization is an outcome of production and sales planning. Early in the product remanufacturing business, we found production planning challenging because we knew nothing of the timing and number of used products to be collected. We resolved that issue in 2005 by deploying a technique to forecast takeback volumes and establishing a recovered machine management system. We can now predict when and how many units of specific models that we will collect around Japan, enhancing production and sales planning precision.

5. Ensuring Quality and Data Security

Remanufactured products undergo the same quality assurance steps as new models and also need data security and other processes. With remanufactured products, for example, we need to fully erase hard disk drives through traceability management. The British Standards Institution, a global business standards body, has certified remanufacturing processes at Ricoh Industrie France and Ricoh UK Products since 2012.

6. Building a Global Structure

We have rolled out our Japanese domestic expertise and technologies at recycling sites overseas. In recent years, we have shared reuse and recycling technologies among recycling sites, including sales offices. We meet growing demand for used products by supplying recovered and remanufactured products from developed nations, where such volumes are high, to emerging markets in Asia and China* to balance global supply and demand.

* In 2015, Ricoh became the first Japanese manufacturer to obtain approval from the General Administration of Quality Supervision, Inspection, and Quarantine of China to import used products into that country for locally manufacturing recycled MFPs.

7. Selling Remanufactured Products

We have sold remanufactured products since 1997, tailoring our operations to regional market needs.

We offer several types of remanufactured product types to cater to customer and market requirements.

- High-quality remanufactured products with as-new warranties

- Refurbished products that we have inspected and replaced with consumable parts

- Cleaned and Checked refurbished products

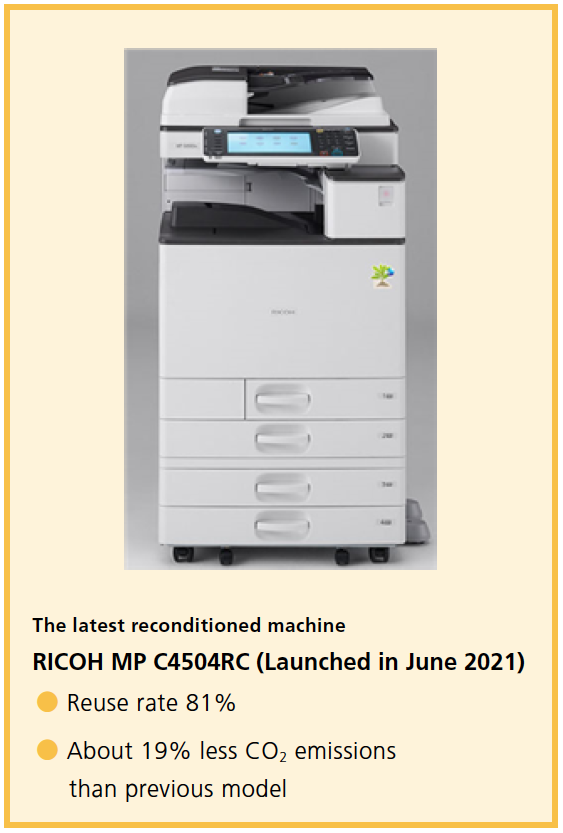

We guarantee high-quality remanufactured products to be as good as new. We market them as reconditioned machines in Japan and as the GreenLine series in Europe, the Americas, and elsewhere in Asia.

In February 2022, nine models of the GreenLine series models in the Americas became the world’s first remanufactured MFPs to achieve ENERGY STAR certification under specification version 3.1.

Reuse of full-color toner bottles without disassembly

Toner containers for RICOH IM C8000/C6500 and RICOH Pro C5310S/C5300S are remanufactured without disassembly. We have launched a global initiative to remanufacture color toner containers, in which we collect some of the used toner containers returned by customers, clean them, fill them with new toner, and deliver them to customers again. In order to realize toner container remanufacturing, we have developed a technology for diagnosing the life of specific parts and a technology for cleaning the inside of the toner container without disassembling it. The annual reduction of new resources by remanufacturing toner containers is about 36t/year, and CO2 reduction is about 210t of CO2/year.

RICOH IM C6500 Toner bottles (front door open)

Audit of Industrial waste disposal company

Using the system to check the vendor

From 2006, we implemented a system to audit waste contractor disposals and operations to fulfill our responsibilities as a waste producer. The annual audit encompasses waste management perspectives and everything from fire and disaster prevention to health and safety, workplace environments, recycling situations, in addition to perspectives related to waste management. We use laptop PCs in site visits, storing findings in real time on the cloud. Checks require wide-ranging expertise, so we set up a team of experienced auditors at Ricoh global headquarters. The system centrally manages audit findings and basic contractor information, which the team can access as needed. The system also manages expiration dates of contractor waste disposal permits. It emails relevant contractor officials before those dates to remind them to stay current.