- Home

- Technology

- Ricoh's Technology

- Fast Inkjet Printing Based on a Three-Printhead Staggered Array

Fast Inkjet Printing Based on a Three-Printhead Staggered Array

Background

With signage, wallpaper products, and the like, industrial printing requires delivering numerous high-quality items in small lots with a quick turnaround. Thus productivity is paramount for industrial inkjet printers.

Technical Highlights

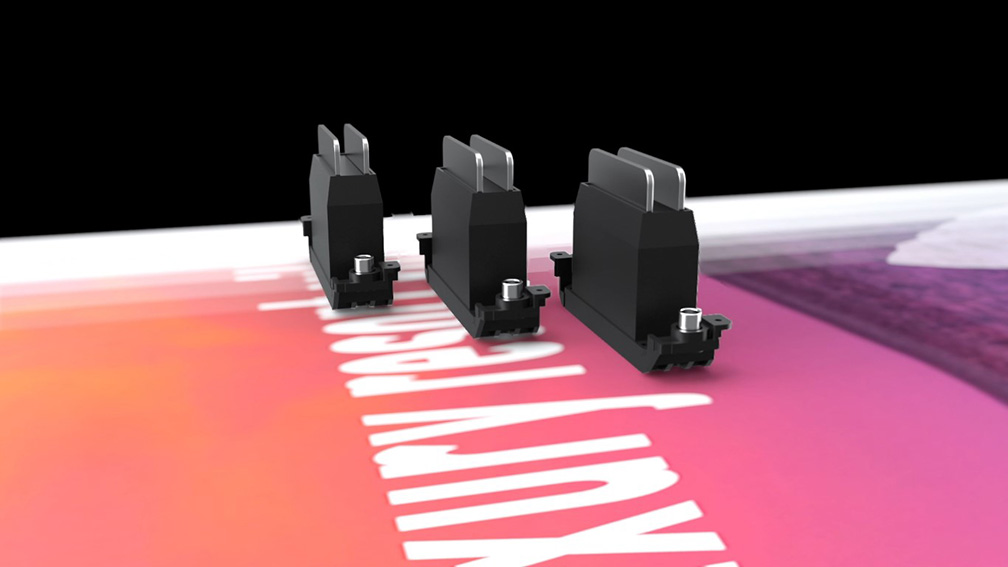

On the RICOH Pro L5130e/L5160e wide-format production printers, the carriage reciprocates on a rail. (The carriage is the printing parts mounting base that includes the inkjet printheads and sensors.)

Precision positioning of inkjet printheads

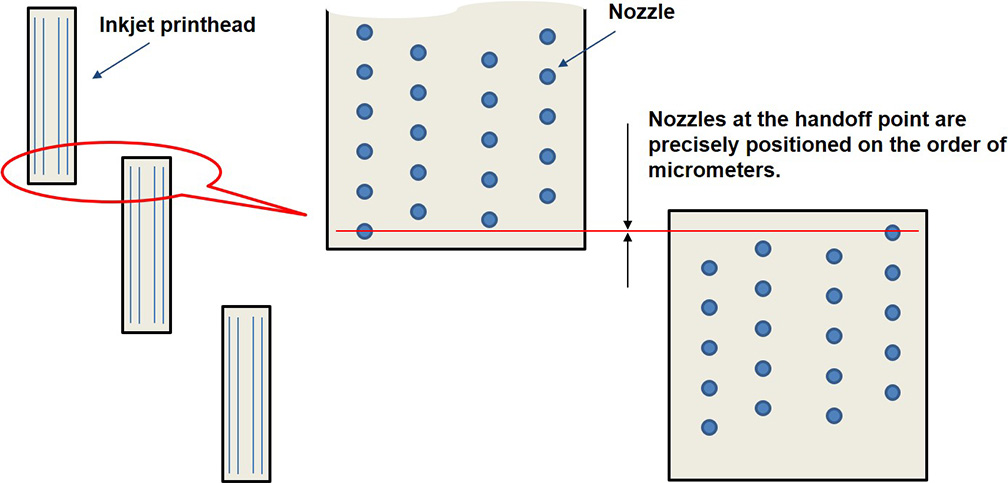

The three inkjet printheads are positioned with high precision: their handoff accuracy is on the order of micrometers. This precision enables a printing width of approximately 150 mm per scan, three times that of a conventional model.

Figure: Accurate handoff between inkjet printheads

Figure: Accurate handoff between inkjet printheads

Low carriage vibration

The carriage reciprocates with the inkjet printheads mounted on it. If the carriage vibrates, it will result in uneven density because the ink dots from the first and the third printheads will not be aligned as targeted.

To resolve this problem, Ricoh has developed a high rigidity drive mechanism that suppresses carriage vibration. Further, Ricoh's original assembly technology ensures absolute carriage rail straightness. Thanks to accurate positioning, printed images are no longer affected by carriage vibration.

Figure: Rail straightness and carriage vibration

Accurate media advance

For printing with the staggered array of three printheads, the media must be advanced over longer distances. For quality printing, accuracy must be maintained over that distance; the ink dots deposited during a scan must seamlessly blend with those during the following scan 150 mm ahead. Ricoh has developed a precision media advance technology that can feed the media the same distance uniformly. The accurate ink dot positions ensure high-quality print levels without any unevenness in density.

High productivity

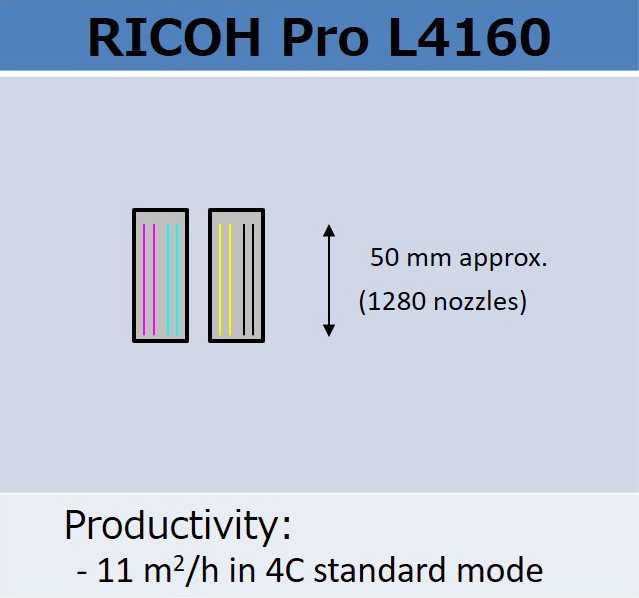

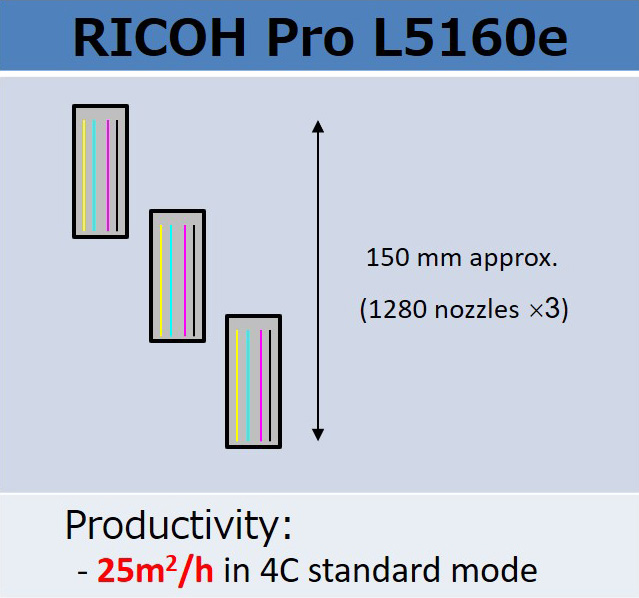

The RICOH Pro L4160 featured two parallel printheads, with a productivity yield of 11 m2/h in standard mode. The RICOH Pro L5130e and RICOH Pro L5160e more than double the productivity yield while maintaining the same or higher print quality.

Figure: RICOH Pro L4160 and RICOH Pro L5160e

Ricoh's Vision

Ricoh has achieved high productivity and high image quality with the 3-head staggered array by leveraging its inkjet technology cultivated over many years and its overall technology expertise from inkjet printhead, ink, body design, and production.

Ricoh is committed to contributing to the total productivity of its customers. In the future, Ricoh will contribute to improving customers' total productivity by enhancing usability and simplifying the printing preparation process.

Related information

Sorted by : field “Inkjet” | product type “Inkjet” “Inkjet printheads”