- Home

- Technology

- Ricoh's Technology

- 40-Channel Vertical Cavity Surface Emitting Laser (VCSEL) Array

40-Channel Vertical Cavity Surface Emitting Laser (VCSEL) Array

Ricoh's academic paper on the VCSEL technology, “Low Thermal Resistance 780nm GaInPAs/GaInP 40ch VCSEL Array for Laser Printers,” won “An MOC Paper Award” at MOC2011 (17th MicroOptics Conference).

Offset print quality

Conventional commercial printing and mass printing are dominated by offset printers. Digitization, however, has been under way in this field in recent years, with increased demand for variable printing (personalization) and liaising with digital image processing. One result of Ricoh's proactive response to these needs is a newly developed 40-channel Vertical Cavity Surface Emitting Laser (VCSEL) Array (Figure 1).

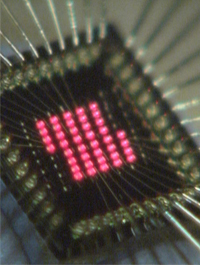

Figure 1: Ricoh's 40-channel VCSEL whose chip size is less than 1mm2

Figure 1: Ricoh's 40-channel VCSEL whose chip size is less than 1mm2

Ricoh's VCSEL achieved the industry's highest density (4800dpi), with the ability to emit 40 laser beams simultaneously as a light source for the optical recording device of a production printer or high-speed copier. This achieves high-speed and high-definition printing equal to that of offset printing, resulting in vivid images and crisp and clean characters/narrow lines.

What is VCSEL?

VCSEL is a surface emitting laser diode that features the fabrication of a two-dimensional arrangement of the beam; density of the laser beam can be significantly increased in a smaller space than with the conventional edge type laser diode. No commercialized VCSEL for digital printers and copier machine was before possible, however, because of difficulties in fabricating a high-power VCSEL that satisfied printer specifications.Ricoh has successfully overcome those difficulties by developing this original VCSEL designed with a high-quality vertical cavity.

Ricoh's VCSEL that made 4800dpi writing unit possible

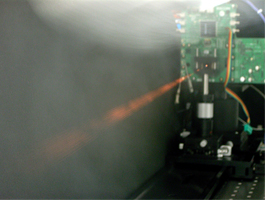

Figure 2 shows the tire track of all 40 beams emitting from Ricoh's VCSEL. Ricoh developed this 40-beam writing unit a world first. With this achievement, Ricoh's printing technology boasts the industry's highest pixel density (4800dpi).

* White mist makes the beam visible.

* White mist makes the beam visible.

Figure 2: Light-emitting experiment of 40-channel VCSEL

VCSEL technologies towards high image quality, high speed and reliability

The goals of VCSEL research and development were the industry's highest pixel definition, its highest printing speed, and its highest-reliability in obtaining stable image quality. To achieve these goals, Ricoh developed the following additional technologies derived from the 40-channel VCSEL.

(1) Technologies for high pixel density to improve image quality

One feature of Ricoh's VCSEL is its 40-channel bits arranged in a space of less than 1mm². An original VCSEL driver was developed to expand the 40 beams to the industry's highest density pixels on paper. This driver sharply improves response in optical output, and slanted narrow lines and isolated dots excel in image reproducibility. The driver chip is placed beside the VCSEL chip and controls the 40 beams individually by high-speed modulation.

(2) Device design of the high power VCSEL for high-speed printing

To gain high printing speed, a high power writing unit with high quality optical beams was required. In developing the VCSEL, to satisfy this requirement, Ricoh developed an original active layer and optical filter layer for the 40-channel VCSEL. An active layer with high efficiency and improved thermal conductivity was realized using a new material with low thermal resistance. And high optical quality was achieved using an original new filter, which suppresses higher modes. As a result, Ricoh's VCSEL leads the industry with the highest output power with high quality optical beams.

(3) VCSEL reliability with stable image quality during printing

To ensure high-quality printing of images, stability of the light source is an important characteristic of the writing unit. Ricoh's VCSEL achieves long-time beam stability, long-life, and good element robustness by employing newly developed process technologies and a highly thermal conductive structure.

With these solutions, Ricoh has made it possible to form images at higher speed and quality than ever.

Practical use of VCSEL

Ricoh's 40-channel VCSEL was adopted for Color Production Printers “RICOH Pro C5100S/C5110S”, “RICOH Pro C7100/C7110X Series”, “RICOH Pro C651EX/C751/C751EX”, “RICOH Pro C9100/C9110”, Black and White Production Printers “RICOH Pro 8100S/8110S/8120S”, Multifunction Color Printers “RICOH MP C6502SP/C8002SP”.

Applied development of VCSEL

Furthermore, Ricoh has developed a “High-Power VCSEL Module” by increasing the luminescence efficiency of the VCSEL elements. It has also achieved large-scale integration of the light-emitting channels and together they significantly boost the output power of the laser array. The High-Power VCSEL Module incorporates three technological advances, namely high output performance, compact size and wavelength stability in variable temperatures. Ricoh is also looking to expand into applications such as laser processing machines, surface treatment processing such as laser patterning, non-thermal processing and sensing, as well as the development of other applications.

Sorted by : field “Electrophotographic” “Devices” | product type “Printing” “Electrophotographic”

- Low Thermal Resistance 780nm GaInPAs/GaInP 40ch VCSEL Array for Laser Printers (PDF:1004KB) (Source: MOC2011(17th MicroOptics Conference)) * This paper won “An MOC Paper Award” at MOC11.

- High Speed Digital Full Color Printer RICOH Pro C900 (PDF:913KB)