- Home

- Sustainability

- Society

- Supply Chain Management

Supply Chain Management

Policy and Basic Concept

Our business activities give us a large sphere of influence when it comes to social accountability, so it is crucial for the many companies and individuals along our supply chain to help the Ricoh Group avoid or minimize unintended negative effects. We are a member of the RBA*1 (Responsible Business Alliance), a global industry coalition dedicated to progressing social responsibility in global supply chains and we make sure not only our employees, but also the employees of our suppliers, always act ethically. We spotlight this concern in our international guidelines on human rights, labor, the environment and more, and are working continuously to raise our initiatives to the next level.

*1 RBA: Responsible Business Alliance, organizations promoting CSR in supply chain

Ricoh Group basic policy in procurement activities

The Ricoh Group’s businesses are supported by many suppliers. Recognizing these suppliers as our essential business partners, we build a relationship of trust with them, aiming at mutually beneficial development.

Today’s society faces various issues to address, such as those associated with the environment and human rights. To help solve these issues and achieve a sustainable society, the Ricoh Group promotes business activities so as to achieve SDGs, upholding the slogan of “Driving Sustainability for Our Future.” In order to effectively pursue this goal to meet social expectations, we need to cooperate with the entire supply chain, sharing our group policies and visions with individual suppliers. To this end, we have established the Ricoh Group purchasing regulation to appropriately deal with relevant CSR issues involving legal compliance, fairness and environmental and societal impacts. Using this as a tool, we are working to enhance our efforts on a global scale.

Ricoh Group Purchasing Regulation

To operate the purchase activities in impartial and fair manner which is open to all over the world, based on the economic rationality.

To operate, as a member of the global citizen, the purchase activities in such a manner as to contribute to the conservancy and the improvement of the global environment.

To operate the purchase activities bearing in mind CSR and based on the compliance with law and esteem of the social ethics.

To aim at coexistence and co-prosperity with excellent Suppliers on the basis of mutual responsibility.

Ricoh Group supply chain

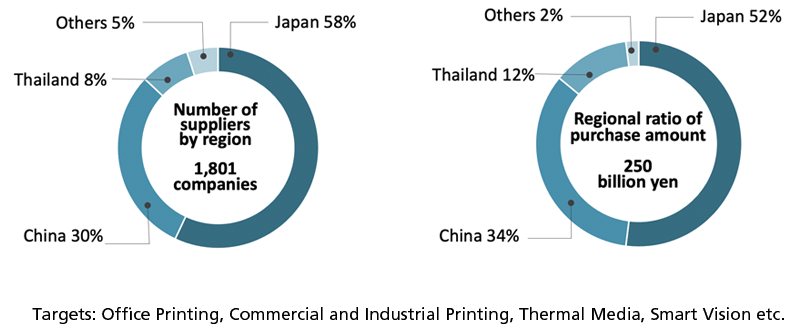

On a global basis, the Ricoh Group has 1,801 supplier companies, with a purchasing amount of 250 billion yen (as of March 2023). We work to achieve group-wide procurement optimization in cooperation with our global suppliers.

Critical suppliers selection process

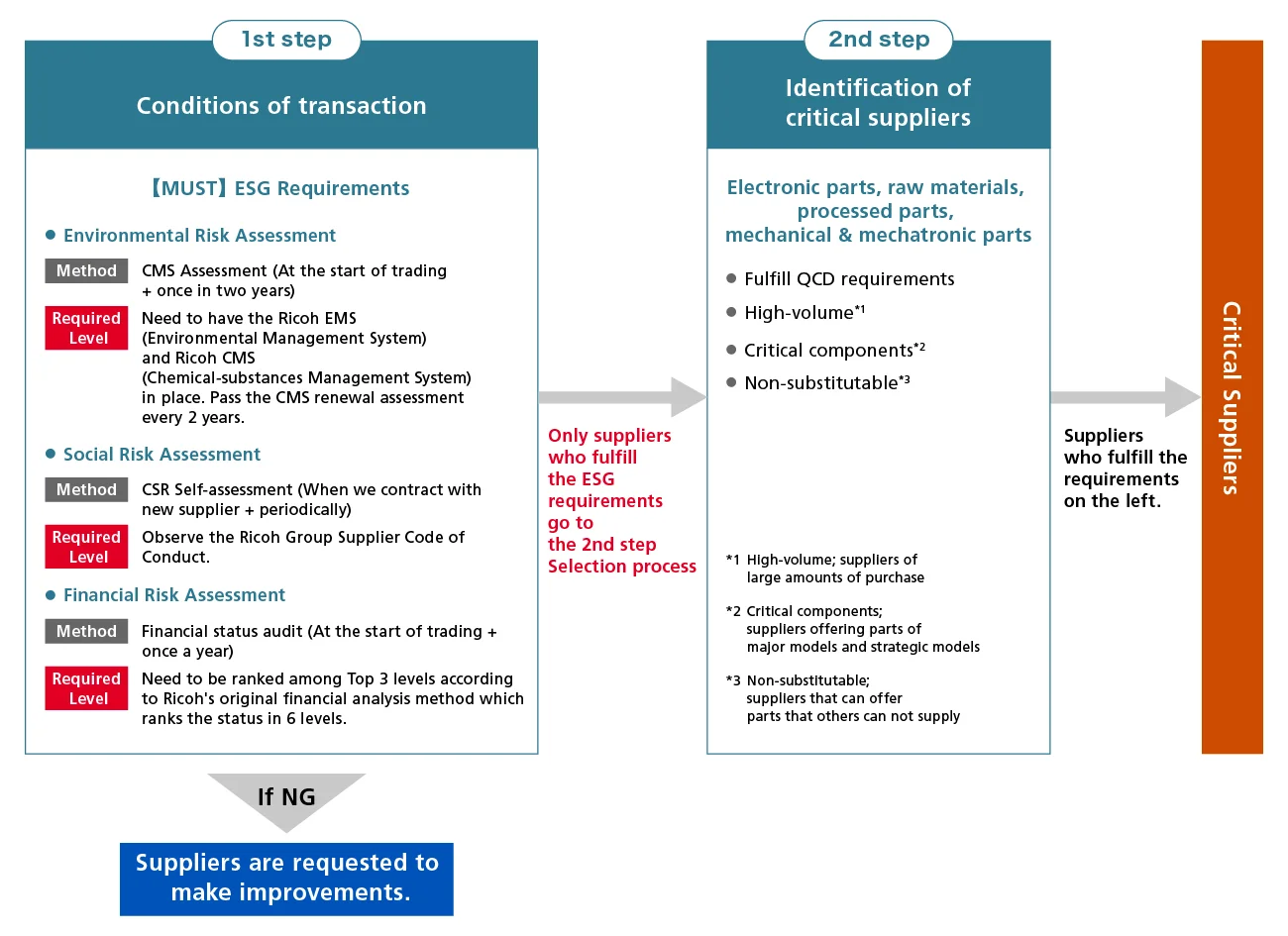

We identify critical suppliers according to certain criteria, taking into consideration the procurement amount and volume, the importance and substitutability of procured materials and parts, as well as the risk of not being able to procure parts because of politics, regulations, labor conditions, energy consumption, potential pollution, etc. in the country concerned.

As of March 2023, a global total of 216 companies have been specified as critical suppliers.

【First Step】

When starting a new transaction, we select suppliers in accordance with the basic policy in purchasing activities, and include provisions related to ESG (Environment, Social and Governance) in the basic business agreement.

【Second Step】

From among the suppliers selected as satisfying the first step requirements, those involving large purchasing amounts, components for key products and strategic models, and non-substitutable parts plus the risk of not being able to procure parts are specified as “critical suppliers.”

Building relationships with suppliers based on trust

We work to forge relationships of strong trust and long-term cooperation with our suppliers, aiming at mutually beneficial development. We do this by providing:

- The Ricoh Group Supplier and Partner Code of Conduct

- Production trend briefings

- ESG briefing for suppliers

We provide education and training to our suppliers through the ESG briefing. We started by explaining basic matters such as Ricoh's initiatives and the Supplier and Partner Code of Conduct, and now we are explaining more advanced matters such as setting decarbonization targets, conducting CSR audits, and implementing improvement programs for suppliers that we have identified as high risk. Since 2020, for the purpose of preventing the spread of Covid-19, we have held online-briefings for the first time with our main global suppliers. - Supplier Satisfaction Survey

We conduct questionnaires for suppliers about Ricoh's procurement activities anonymously, and we improve Ricoh's own procurement activities based on the answers of questionnaires.

To join the Responsible Business Alliance (RBA)

In November 2019, Ricoh joined the Responsible Business Alliance (RBA), the world’s largest industry coalition dedicated to promoting corporate social responsibility in global supply chains. Ricoh shares the principals and goals of the RBA and has committed to adopting and implementing the measures initiated by the RBA, and also sharing them with our suppliers.

Furthermore, we are utilizing the RBA-Online platform, which is the platform of the RBA, to receive various data from our suppliers regarding their initiatives on environmental, social, and governance (ESG) practices. We use RBA's management indicators as benchmarks to collaborate with our suppliers in addressing and reducing ESG risks, with the aim of promoting sustainable business activities. Our suppliers actively participate by exchanging information on initiatives such as hosting ESG briefing, implementing power reduction programs to promote decarbonization, and various other efforts. Additionally, Ricoh provides support by actively advising and assisting in these initiatives.

In accordance with RBA's certification program, our global production sites have adopted take RBA's Self-Assessment Questionnaire (SAQ) and the Validated Assessment Program (VAP), a formal third-party audit. The VAP also evaluates the number of suppliers and the number of assessments conducted, the number and progress of high-risk supplier improvements, and the number and status of companies implementing improvement support programs.

In previous audits, there have been no instances of non-compliance evaluations regarding the quantitative data submitted to the auditing agency. Among the three certification ranks available (Platinum/Gold/Silver), all audited locations have obtained either Gold/Silver certification.

For a list of certified production facilities, please refer to the Human Rights page.

Ricoh Joins the Responsible Business Alliance, the World's Largest Industry Coalition Dedicated to CSR in Global Supply Chains

Responsible Business Alliance (RBA)

Validated Assessment Program (VAP)

Human Rights

Ricoh Group Supplier Code of Conduct

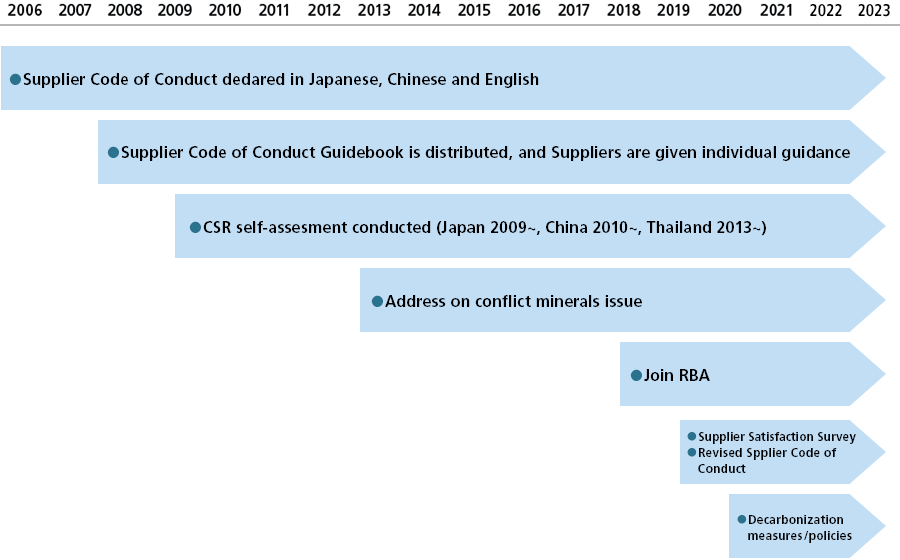

In January 2006, the Ricoh Group established the Ricoh Group Supplier Code of Conduct for our suppliers to help them understand and support the Ricoh Group’s basic CSR policy and promote efforts aimed at improving society and the global environment as well as the sustainable development of businesses. The code of conduct is distributed to all our suppliers, who are required to comply with it. In August 2020, the Ricoh Group revised the "Supplier Code of Conduct" complying with the RBA Code of Conduct, which is based on major international human rights standards, including the ILO Declaration on Fundamental Principles and Rights at Work and the Universal Declaration of Human Rights in line with the UN Guiding Principles on Business and Human Rights. In April 2023, we revised the code to the "Ricoh Group Supplier and Partner Code of Conduct" as a code of conduct to be applicable to business partners in addition to suppliers of the Ricoh Group.

For suppliers and business partners implementing the Supplier and Partner Code of Conduct, the working environment is safe, and the workers are treated with respect and dignity. We would also like our suppliers and partners to ethically work on this revised Code of Conduct for conducting business and, at the same time, to be environmentally responsible. We request our suppliers and partners to sign the agreement form for the Ricoh Group Supplier and Partner Code of Conduct and ensure that Ricoh and our suppliers work in tandem. In fiscal 2022, we have received consent from 98% critical suppliers.

Ricoh Group Supplier and Partner Code of Conduct

Ricoh Group Supplier and Partner Code of Conduct (English) (285KB)

Ricoh Group Supplier and Partner Code of Conduct (Japanese) (416KB)

Ricoh Group Supplier and Partner Code of Conduct (Chinese) (577KB)

Ricoh Group Supplier and Partner Code of Conduct (Thai) (253KB)

Ricoh Group Supplier and Partner Code of Conduct Agreement form

Ricoh Group Supplier and Partner Code of Conduct Agreement form (English)(24KB)

Ricoh Group Supplier and Partner Code of Conduct Agreement form (Japanese)(98KB)

Ricoh Group Supplier and Partner Code of Conduct Agreement form (Chinese)(92KB)

Ricoh Group Supplier and Partner Code of Conduct Agreement form (Thai)(104KB)

The RBA Code of Conduct

The RBA Code of Conduct

Ricoh Group Supplier and Partner Code of Conduct (Index)

Ricoh Group Supplier and Partner Code of Conduct is based on the RBA Code of Conduct and consists of five sections: labor, health & safety, environment, ethics and management systems.

A. LABOR

- Freely Chosen Employment

- Young Workers

- Working Hours

- Wages and Benefits

- Humane Treatment

- Non-Discrimination/Non-Harassment

- Freedom of Association

C. ENVIRONMENT

- Environmental Permits and Reporting

- Pollution Prevention and Resource Reduction

- Hazardous Substances

- Solid Waste

- Air Emissions

- Materials Restrictions

- Water Management

- Energy Consumption and Greenhouse Gas Emissions

E. MANAGEMENT SYSTEMS

- Company Commitment

- Management Accountability and Responsibility

- Legal and Customer Requirements

- Risk Assessment and Risk Management

- Improvement Objectives

- Training

- Communication

- Worker Feedback, Participation and Grievance

- Audits and Assessments

- Corrective Action Process

- Documentation and Records

- Supplier Responsibility

B. HEALTH AND SAFETY

- Occupational Safety

- Emergency Preparedness

- Occupational Injury and Illness

- Industrial Hygiene

- Physically Demanding Work

- Machine Safeguarding

- Sanitation, Food, and Housing

- Health and Safety Communication

D. ETHICS

- Business Integrity

- No Improper Advantage

- Disclosure of Information

- Intellectual Property

- Fair Business, Advertising and Competition

- Protection of Identity and Non - Retaliation

- Responsible Sourcing of Minerals

- Privacy

CSR procurement briefing sessions

CSR seminar (Ricoh Headquarters Tokyo)

CSR seminar (Ricoh Headquarters Tokyo) ESG briefing sessions at affiliated company (Dongguan, China)

ESG briefing sessions at affiliated company (Dongguan, China)We host procurement briefing sessions for major suppliers to explain our procurement policy as well as to boost their understanding of the Ricoh Group’s CSR policy. The Ricoh Group's day-to-day stable production activities are the result of the cooperation of our suppliers, and we consider that the briefing sessions are opportunities to build further win-win relationships. In 2019, we held procurement briefing sessions in China (Shanghai and Shenzhen) and Thailand (Bangkok).

We also hold CSR seminars (renamed ESG briefing in fiscal 2021) for suppliers to engage in CSR activities in tune with the entire supply chain. Since fiscal 2020, we have been holding events in a hybrid format, combining online and in-person components, due to the impact of Covid-19. We share information with our suppliers on social topics such as global environmental issues, the significance of the SDGs, and policies and targets of the Ricoh Group. In addition, we implement CSR self-assessment based on the RBA Code of Conduct and confirm the situation of ethics, environment, human rights, labor, safety, and health, etc. In feedback, we show their compliance level of the codes, suggesting not only items for improvement, but also highlighting specific areas in which they excel, and we try to communicate interactively. We also work in tandem with high-risk suppliers to help them improve their management. Together with the supplier's management and employees, improvement measures are developed and implemented, and follow-up audits are even conducted to check the situation afterwards.

Supplier Satisfaction Survey

We aim for coexistence and co-prosperity and sustainable development through fair corporate business activities with suppliers. A pilot survey was launched in fiscal 2020 followed by a full-scale supplier satisfaction survey in fiscal 2021. We conduct a questionnaire for our suppliers covering the following points: listening to the frank opinions of anonymous respondents and improving Ricoh's procurement activities. The 2022 survey was conducted using the same questions as in the 2021 fiscal year to assess the improvement status. It consisted of eight questions divided into four categories, aiming to obtain numerical evaluations and specific feedback regarding Ricoh's purchasing activities.

In fiscal 2022, we conducted the survey in Japan, China, Thailand, and Vietnam, targeting important suppliers who have a large volume of business with the Ricoh Group, and received responses from approximately 60% of suppliers. According to the survey results, 68% of suppliers were satisfied with Ricoh's purchasing activities, indicating that there is still much room for improvement. Looking at the feedback we received from suppliers, we found that they were generally polite and gentlemanly, but we did receive one comment that "there are very rare cases where the person in charge uses bad language. We also received some comments on things that need to be improved, such as "sometimes we feel a lack of communication between locations" and "production plans fluctuate. We have provided feedback on the results of the survey to those who were asked to participate in the supplier satisfaction survey. This year, we plan to implement improvement measures for purchasing activities.

Addressing CSR procurement

While operating the business globally, the Ricoh Group considers the ESG in the supply chain and responds to the challenges of each field, aiming to solve social issues and to become a company in which employees can be even more proud of their work. We believe that working together with suppliers to address and solve the various problems of the global environment and society will be the driving force for the development of a healthy company and, ultimately will realize a sustainable society. For that we will promote this initiative from the perspective of long-term corporate value improvement.

In the supply chain, we have established and are implementing specific goals to expand the number of low-risk suppliers that meet a high degree of ESG requirements, leveraging our past performance and experience. We have made organizational changes to strengthen governance and promote the expansion of suppliers that meet ESG requirements.

In December 2021, we organized a company-wide control department for ESG-related purchasing and procurement, and work to expand the number of low-risk suppliers through initiatives to support the achievement of ESG risk management standards required by the Ricoh Group.

Rollout of supply chain CSR

Education and training in the procurement division

To promote CSR procurement throughout the supply chain, it is essential for employees in procurement divisions to be aware of social and environmental issues in the supply chain. As well as offering CSR procurement training for employees new to purchasing operations, Ricoh's Procurement Division holds monthly meetings with the ESG Division to confirm and understand global sustainability trends and CSR procurement requirements from society and customers. In addition, in order to respond to various social and environmental issues, including the reduction of GHG emissions and the environmental impact throughout the supply chain, which have recently become issues that must be addressed, we have established a working group within the Procurement Division to collect data on ESG requirements and enhance our current CSR procurement activities. We are working to enrich the level of our CSR procurement activities by expanding our understanding of ESG requirements and expectations.

Green procurement

To reduce the environmental impact of its entire supply chain, the Ricoh Group works to enhance environmental protection efforts in cooperation with suppliers. As a measure to facilitate relevant efforts at suppliers to establish the Ricoh Group’s environmental management system (EMS), we have created the EMS Guidelines and Green Procurement Standard, to which we refer for purchasing raw materials and components from suppliers. Similarly, to help suppliers establish a chemical substance management system (CMS), we have developed the CMS Guidelines, and use it as a tool for providing training and operational support.

Supply chain chemical substance management system

Supplier CMS Training

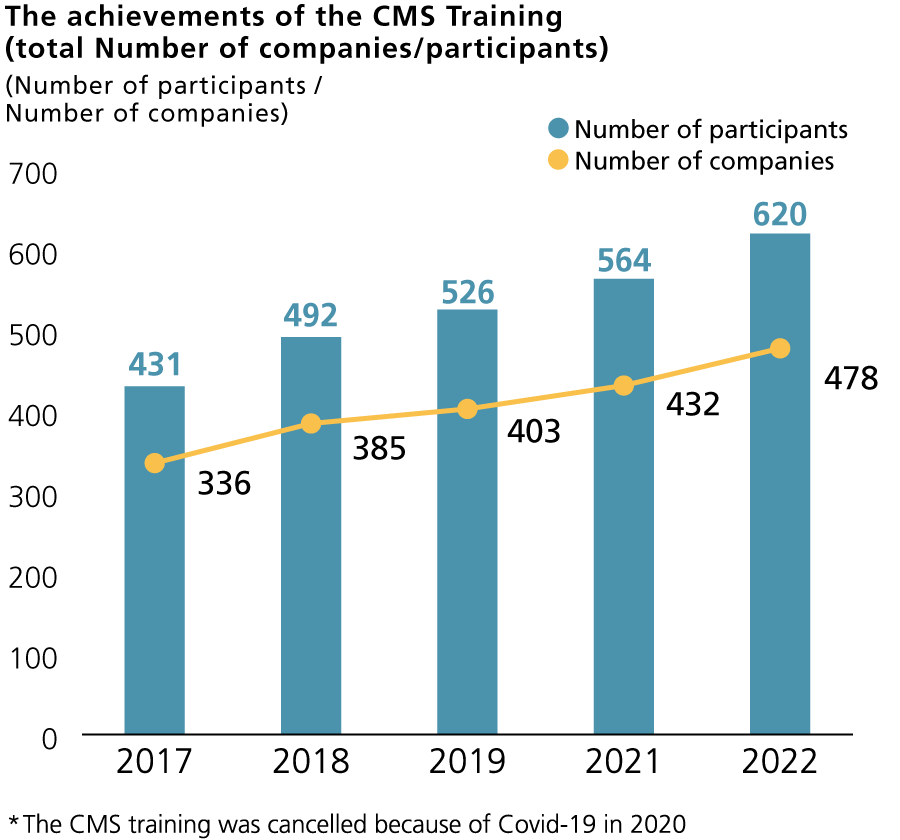

Supplier CMS TrainingTo help establish a chemical substance management system (CMS) across its entire supply chain, the Ricoh Group commenced a program in fiscal 2005 to train and certify suppliers’ employees as CMS examiners. In addition to internal audits facilitated by their own companies, certified examiners will conduct audits upstream suppliers that deal with important processes involving environmentally sensitive substances and will support them in establishing a CMS.

In Japan, we continuously conduct CMS auditor training sessions to provide technical support for chemical substance management. The first half of the training session consists of a classroom lecture focusing on CMS knowledge and past cases, and the second half is a role-playing session for CMS audits, training participants to use the knowledge and skills they have acquired in practical situations and to teach others. We will continue to improve the level of our judges in the future.

Targets and achievements of the CMS Training

| FY | Number of companies | Number of participants | Rate of passing test (target / achievement) |

|---|---|---|---|

| 2017 | 76 | 91 | 100%/100% |

| 2018 | 49 | 61 | 100%/100% |

| 2019 | 18 | 34 | 100%/100% |

| 2020 | — | — | Cancelled due to coronavirus effects |

| 2021 | 29 | 38 | 100%/100% |

| 2022 | 46 | 56 | 100%/100% |

The achievements of the CMS Training

Supporting suppliers’ decarbonization efforts

In pursuit of a zero-carbon society, the Ricoh Group is expanding its CO2 emissions reduction activities that allow suppliers to join in with the Group’s efforts. One such activity involves supporting suppliers in switching to clean electricity. We have shared the global warming countermeasures and information of trend on the environment that became a common global issue after the Paris Agreement with the management of suppliers in order to aim to raise awareness about CO2. In 2021, we held an ESG briefing session to explain the Ricoh Group's policy on decarbonisation and future initiatives to suppliers and asked for their cooperation. Besides, based on practical cases and know-how in the Ricoh Group, we have supported suppliers on CO2 emissions reduction activities. In the future, together with our suppliers, we will continue to practice environmental management that realizes environmental conservation activities and creation of profits.

Case report: Supporting suppliers in switching to “new power” to reduce CO2 emissions

Miyazawa Machinery Industrial Co., Ltd. (Head office/plant in Omori-honcho, Ota-ku; plant in Jonanjima, Ota-ku; Website: http://www.m-mic.co.jp/)

Interview with Taizo Miyazawa, Representative Director

How did your company begin working to reduce CO2?

We have been promoting energy conservation over several years in our major business sites at the head office and at plants. We installed LED lighting, energy saving air conditioners and other systems. In the summer of 2018, we received a request from Ricoh to switch to “new power,” which is provided by a power producer and supplier (PPS). Ricoh explained in earnest about the objective of promoting the initiative and its effect on society, which made us consider accepting their request. However, the switch was difficult to do immediately at the time, given the need to fulfill our ongoing contract for multi-year services. We decided to bring forward the issue for reconsideration when that contract expires.

What made your company adopt the CO2-free option?

Ricoh offered to provide their accumulated know-how and operational support for switching to new power. We began to consider the possibility of the switch as an approach to cutting costs and CO2 emissions at once. The company invited us to CSR briefing sessions and SDGs seminars, where we were impressed by their eagerness for environmental initiatives. As a parts supplier, we thought we should support Ricoh in pursuing the initiatives and decided to introduce new power. Our decision was driven particularly by a plan that could allow us to select a CO2-free option and lower costs compared with the service by the previous power company. We became the first supplier to respond to Ricoh’s request, which also boosted our motivation.

What are your future plans?

Following the power company change, we plan to reduce power usage in order to further facilitate CO2 emissions reduction. The Ricoh Group will also help us for this purpose, such as by sending specialists to provide know-how for power usage data analysis. Working with Ricoh, we will make continued efforts to reduce CO2 emissions and contribute to achieving SDGs to create a sustainable society.

Suppliers implementing CO2 reduction activities

Suppliers implementing CO2 reduction activities: (originally) 44 companies

Reduction amount of CO2 emissions 986 tons

| company | website |

|---|---|

| IKEDA-KOKI inc. | http://www.ikeda-koki.co.jp/company/company.html |

| KISHIRO HIKARI KAGAKU CO.,LTD. | http://www.kishiro.co.jp/ |

| KOUKIKASEI Co.,Ltd. | https://kouki-kasei.jimdo.com/ |

| SHIZUKOH SANGYOH CO.,LTD. | http://www.shizukoh.com/ |

| SEKI-SEISAKUJYO Co.,Ltd. | https://www.seki-seisakujyo.com/ |

| DAIICHI KOHKI CO.,LTD. | http://www.d1k.co.jp/ |

| TOKYO PLASTICS INC. | http://www.tokyo-plastics.co.jp/ |

| NISSHIN Co.,Ltd. | http://www.nisshin-corp.com/index.php# |

| HANEDA UNITEC CO., Ltd. | http://www.haneda-unitec.jp/ |

| MIYAZAWA MACHINARY INDUSTRIAL co., ltd | http://www.m-mic.co.jp/ |

Support to suppliers’ process improvement

We promote cost reduction programs jointly with suppliers to build long-term relationships of trust based on mutually beneficial cooperation. The programs aim to improve profits (financial statements) at our partners, and involve a range of processes, starting from consensus formation at the top management level among relevant companies, followed by sharing and analyzing information, checking facts and inspecting factories to select issues, executing improvement plans and verifying results.

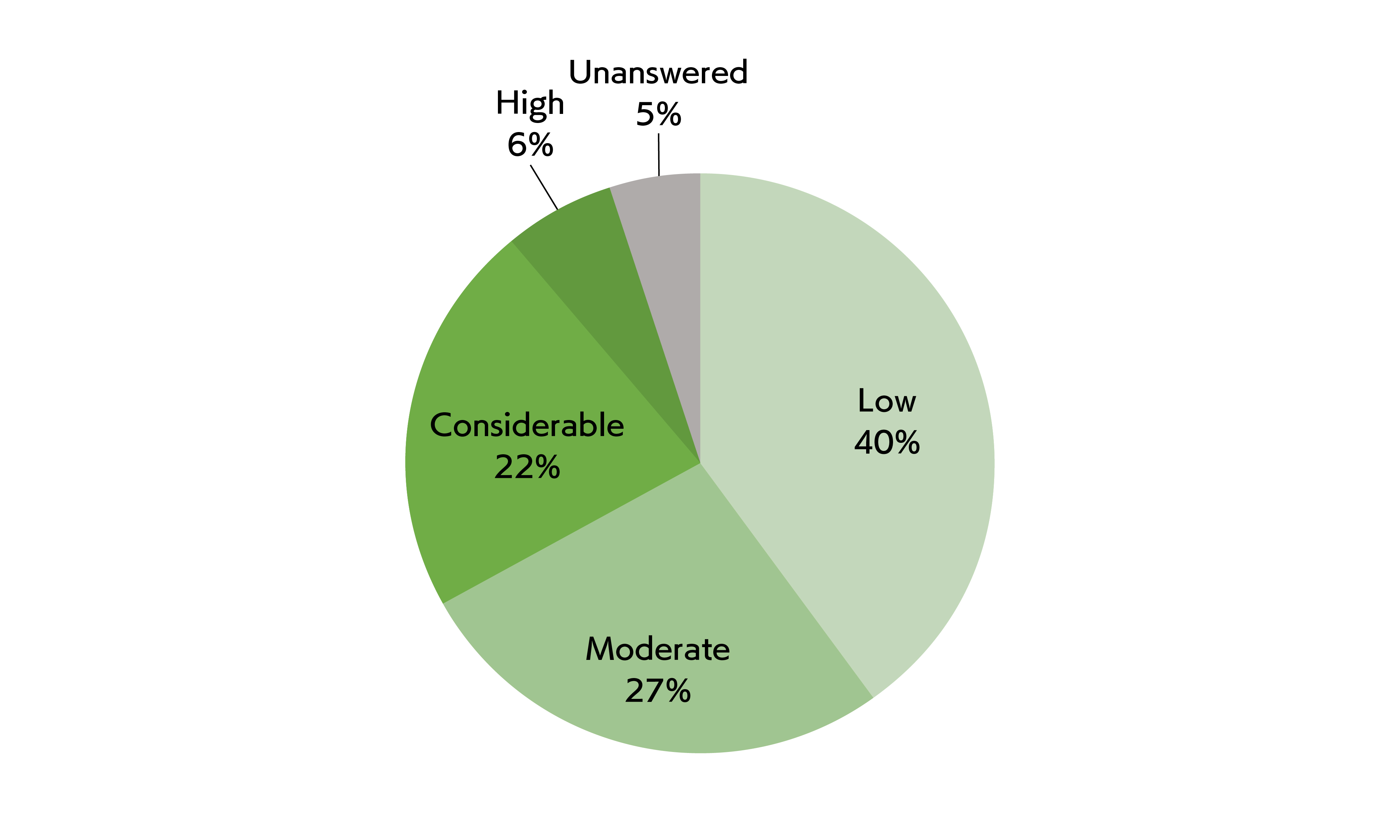

Identifying risks associated with suppliers

We assess risks associated with each supplier in consideration of its location of operation and the possibility of involving environmentally hazardous substances. Based on the assessment, we identify high-risk suppliers and carry out measures to reduce the risk through periodically monitoring the financial situation, introducing the CSR Self-Assessment programs and providing for third-party audits. We also conduct annual compliance risk screening for all suppliers in accordance with our anti-corruption and anti-bribery policy.

In fiscal 2018, we conducted two unannounced audits of suppliers with coating processes suspected of containing or contaminated by prohibited substances. Thorough the inspection of their production sites, we confirmed that all products were lead-free electroless nickel-coated and determined that there was no possibility of the inclusion of prohibited substances.

CSR Self-Assessment System

We have introduced a CSR Self-Assessment System based on the RBA Code of Conduct that helps suppliers monitor their compliance with the Ricoh Group Supplier and Partner Code of Conduct. The system has been rolled out in Japan, China and Thailand. Company activities are assessed in labor, safety and health, environment, ethics, management systems, and living wages to identify issues to address. The results are fed back to the suppliers, who receive requests for improvement if applicable, together with corrective action plan, advice and support on ways to meet society's needs and expectations. If a supplier's improvement activities are not sufficient, we would discuss the future business relationship with the supplier.

With the CSR Self-Assessment System, the Ricoh Group provides our suppliers with support in implementing a "plan, do, check, act" (PDCA) cycle by themselves to meet society’s needs and expectations.

CSR Self-Assessment Targets and Achievements

Ricoh conducts CSR self-assessments for its suppliers, and then formulates and implements improvement measures together with the supplier's management and employees through follow-up audits to check the status afterwards. In fiscal 2018, we launched a new CSR Self-Assessment program based on the RBA Code of Conduct for suppliers in China and Thailand and in August 2020, we revised the Ricoh Group Supplier Code of Conduct. From the analyzed responses (rate: 100%), we identified a number of issues. To address them, Ricoh provides related companies with advice for improvement measures and periodically monitors implementation progress to support their continued efforts.

CSR self-assessment results for fiscal 2022 are as follows.

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 (target) | |

|---|---|---|---|---|---|

| Country | Japan, China & Thailand | Japan, China, Thailand, other Western countries & Asian region | Japan, China, Thailand, other Western countries & Asian region | Japan, China, Thailand, other Western countries & Asian region | Japan, China, Thailand, other Western countries & Asian region |

| Scope | Important suppliers | Important suppliers | Important suppliers | Important suppliers | Important suppliers |

| Number of suppliers | 18 ・Continually implement a new CSR Self-Assessment based on RBA Code of Conduct ・Continually implement site audits (including third-party audits) in Thailand and China |

226 ・A CSR assessment based on RBA Code of Conduct |

161 ・A CSR assessment based on RBA Code of Conduct ・Implements site audits and improvement activities based on results of CSR assessments |

216 ・To conduct CSR self-assessments in accordance with RBA (Responsible Business Alliance) on a global scale. ・To perform CSR audits on suppliers identified as high-risk based on the results of the CSR self-assessments. |

212 (Planned) ・To develop supplier improvement plans for the period up to fiscal year 2025 as part of the 21st Medium-Term Management Plan. ・To aim to expand low-risk suppliers to 90% by fiscal year 2025. |

| Response rates from suppliers (target/achievement) |

100% (achievement) | 86% (achievement) | 93% (achievement) | 95% (achievement) | 100% (target) |

Major targets and achievements regarding social responsibility

*Indicator 5 in Governance category: Response rate for CSR self-assessments by suppliers (%)

Implementation of CSR Audits

For many years, Ricoh has been conducting CSR audits for final product assembly, components, and raw materials. In fiscal 2018, we conducted internal audits of suppliers in Thailand and third-party audits of suppliers in China, both based on the RBA Code of Conduct, and identified issues to be addressed. We provided feedback on the audit results for each supplier and requested corrective actions for areas needing improvements.

In fiscal 2019, we continuously conducted audits based on the RBA Code of Conduct both in Thailand and China. For Thai suppliers, we implemented third-party audits by RBA (VAP audits*2) and urged them to proceed with improvement activities based on the results. In addition, we conducted follow-up audits for Thai suppliers by revisiting their sites to confirm that they were addressing violations of laws, regulations, and the Ricoh Group Supplier Code of Conduct that were pointed out in fiscal 2018 audit.

Since 2020, CSR assessments are carried out on global suppliers―mainly in China, Thailand and Japan,- in accordance with RBA standards to determine supplier risks, after which improvement plans are formulated. Improvement activities are carried out by those suppliers where improvement issues are identified.

In fiscal 2022, a total of 476*3 suppliers, including 216 critical suppliers, were assessed through desktop evaluations and on-site confirmations. Among the critical suppliers, 95% were evaluated and 9 critical suppliers were identified as high-risk. For a total of 9 suppliers, corrective action plans were developed and implemented based on mutual agreement.

In fiscal 2022, a total of 46 suppliers participated in the capacity development support program, accounting for 21% of the critical suppliers.

Moving forward, Ricoh will continue to prioritize the enhancement of organizational capabilities among suppliers and remain committed to the effective implementation of the supplier evaluation program and continuous improvement activities.

In fiscal 2023, an RBA VAP audit conducted in April 2023 at a production site in Thailand identified a case of violation in which an employee of an onsite service provider as our indirect supplier was not properly granted annual leave in accordance with local laws and regulations. After the audit, the production site in question revised its annual leave system and informed its suppliers of the regulations, requesting them to comply with them and prevent recurrence. As a result, when the VAP audit was reassessed in October of the same year, the external auditor found that the specific issues had been corrected. We will continue to request suppliers to comply with the Code of Conduct, and if any violations of the Code of Conduct are found, we will request suppliers to correct them

*2 VAP audits: Validated Assessment Program. Third-party audits of supplier's compliance with the five elements of the RBA Code of Conduct to identify risks and opportunities for improvement.

*3 The total number of companies evaluated for environmental risk, social risk, and economic risk, which are selection criteria for suppliers.

Supplier Awards

Every year, we select suppliers that have demonstrated excellent performance related to product quality, delivery time, environmental protection, environmental practices etc. and made significant contributions to the Ricoh Group’s business development. We set Ricoh Group’s criteria and select suppliers with the result of the latest one year. Manager of Global Procurement Division awards the selected suppliers directly and has built up strong relationships with the suppliers and aimed to goal for achievement of SDGs.

Efforts in Biodiversity Conservation

The Ricoh Group recognizes that biodiversity conservation contributes to the establishment of a rich and sustainable society. In 2009, we established the "Biodiversity Policy" to reflect this commitment. Furthermore, in 2010, we developed the "Ricoh Group Regulations on Wood Materials for Ricoh Group Products" (an expansion of the 2003 "Environmental Regulations for Paper Procurement") to prevent deforestation and ensure socially responsible sourcing of raw materials, including labor considerations.

Addressing human rights issues

Risks associated with human rights are an emerging supply chain management issue. At the Ricoh Group, we request our suppliers to comply with the "Supplier Partner Code of Conduct," which includes the elimination of child labor and forced labor. We also ask responsible individuals to sign the "Ricoh Group Supplier Partner Code of Conduct Agreement Confirmation Form*", while monitoring their compliance through the periodical CSR Self-Assessment program and requesting improvement efforts as necessary.

In response to the UK’s Modern Slavery Act, which came into force in October 2015, we have posted a relevant statement on the website of Ricoh Europe Holdings PLC, our sales arm in Europe. We also address conflict minerals issues carrying out continued activities, including information disclosure.

Efforts to address child labor issues

Child labor is one of the priority issues of the Ricoh Group's TRM (total risk management) efforts, and relevant departments have been engaged in various projects to address child labor issues. The Ricoh Group has already surveyed the compliance with laws that prohibit child labor by manufacturing sites in Japan and abroad. In fiscal 2018, the survey results confirmed that there have been no violations. The self-assessment results from supplier companies also confirmed that there have been no reports of child labor violations. We will continue to monitor child labor.

Addressing the conflict minerals issues

With regard to the responsible supply chain management of minerals from conflict-affected areas and high-risk areas(CAHRAs) like the Democratic Republic of the Congo (DRC) and the adjoining countries, in order that companies respect human rights and avoid contributing to conflict through their mineral sourcing practices, it is expected to cultivate transparent mineral supply chains and companies’ sustainable growth by the righteous decision-making on the mineral resource procurement with a view to enabling countries to benefit from their natural mineral resources and preventing the extraction and trade of minerals from becoming a source of conflict, human rights abuses, and insecurity.

Ricoh Group’s Responsible Minerals Procurement Policy

The Ricoh Group established “Ricoh Group’s Responsible Minerals Procurement Policy” in 2022 to secure transparency in the supply chain with its business partners and ensure responsible mineral sourcing practices because mineral mining or trading in conflict-affected and high-risk areas finances armed groups and fosters conflicts. These activities are also closely related to human rights abuses, labor and important social issues, and other problems such as environmental destruction. We are determined to eliminate conflict minerals from among the raw materials we use, so we are expelling problematic smelters from our supply chain and identifying procured parts.

Ricoh Group’s Responsible Minerals Procurement Policy(149KB)

Conducting Conflict Minerals Survey

Ricoh Group is working to improve the transparency of its due diligence by addressing conflict minerals issues referring to the “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas". We ask our suppliers to use the CMRT (Conflict Minerals Reporting Template) and EMRT (Extended Minerals Reporting Template ) formats provided by RMI (Responsible Minerals Initiative) *3. Our goal is to achieve 100% collection rate for conflict minerals survey response from the suppliers and product-based response by fiscal 2025.

Step1: Establish strong company management systems

In 2012 the Ricoh Group started an in-house study system to approach conflict minerals issues, and we established a cross functional task force in charge of dealing with conflict minerals issues. The task force, which consists of representatives from relevant departments within Ricoh Group companies, began considering what actions to be taken for the issues. We are continuing these activities, led by the Procurement Division and the ESG Division. Each year we plan and carry out an annual Conflict Minerals Survey. From fiscal 2021, in line with the survey policy of “Achievement of conflict-free sourcing”, we have been started to centrally managing the Conflict Minerals Survey data to improve with the aim of improving the efficiency of collecting responses to this survey. In fiscal 2022, we established the “Ricoh Group’s Responsible Minerals Procurement Policy” and asked our suppliers to support and cooperate with the Ricoh Group Conflict Minerals Survey.

〔Education and training on conflict minerals issues〕

At the ESG briefing for suppliers, we address the issue of conflict minerals as one of the themes to ensure that suppliers are provided with information and educational opportunities.

In addition, in conjunction with the annual Conflict Minerals Survey, Ricoh Group provides education on the latest legal amendments and other trends related to responsible mineral procurement and Ricoh Group's Conflict Minerals Survey activities to purchasing and procurement personnel at all Ricoh Group global sites. We also produce videos introducing the significance of the Conflict Minerals Survey and Ricoh Group's initiatives on conflict minerals for all Ricoh Group companies and employees to raise awareness.

Step2: Identify and assess risks in the supply chain

From 2013, we have been conducting a yearly conflict minerals survey targeting suppliers of raw materials and components to be used for the Ricoh Group’s products. Until fiscal 2020, we surveyed suppliers of major products such as imaging products. From fiscal 2021, we expanded the scope of our survey to include all products that Ricoh is responsible for producing and selling and asked our suppliers to limit the scope of the survey to those parts and products that Ricoh Group delivers. In addition, considering the growing concerns about unsafe working environments and child labor in recent years in the mining of cobalt, we have been conducting surveys of the supply chain of cobalt since fiscal 2020. We ask suppliers to use the Conflict Minerals Reporting Template (CMRT) and the Cobalt Reporting Template (CRT), which provides conflict minerals reporting formats provided by RMI*3.

Step3: Design and implement a strategy to respond to identified risks

From fiscal 2020, we provide information on high-risk smelters to our tier 1 suppliers and request them to switch to RMAP(Responsible Minerals Assurance Process) Conformant smelters. We also ask tier 2 and subsequent suppliers to encourage upstream companies and smelters to switch to RMAP Conformant smelters and obtain certification through tier 1. As a result of the analysis of response information, we directly request the switchover of smelters to suppliers who procure from high-risk smelters.

Step4: Carry out independent third-party audit of smelter/refiner’s due diligence practices

Ricoh, as a member company of the "Responsible Minerals Trade Working Group", launched in May 2012 by JEITA*4, is participating in a Working Group for the entire global supply chain, and studying activities unified in the electronics industry. In 2019, the Ricoh Group participated in the RBA (Responsible Business Alliance) and member companies of RMI, to ask the conflict minerals smelters related organizations in Japan to make inquiries about smelters and promote to be the RMAP Conformant continuously.

Step5: Report annually on supply chain due diligence

Ricoh's activities related to conflict minerals are published annually on its website and in the Integrated Report. We have identified that our toner products are conflict-free.

*3 RMI: Responsible Minerals Initiative; former Conflict-Free Sourcing Initiative (CFSI)

*4 JEITA: Japan Electronics and Information Technology Industries Association

Survey conducted in fiscal 2022 and future efforts

In fiscal 2021, based on the results of a survey conducted for worldwide first-tier suppliers of the Ricoh Group , we identified as accurately as possible each of the parts and raw materials used in the products manufactured or consigned during the year, and conducted a common survey on the use of conflict minerals and received CMRT responses from 96% of suppliers. In the survey of 2022, the Ricoh Group identified 229 smelter companies that have acquired the certification of RMAP Conformant and are conflict-free. The rate of RMAP Conformant smelters to the total number of smelters and refineries identified in the Ricoh Group supply chain was 66% in fiscal 2022. In recent years, as the number of companies surveyed has increased, the number of newly specified smelters and refineries that have not obtained RMAP Conformant has been increasing, while the number of RMAP Conformant smelters has been excluded from RMI certified smelter list. As a result, the ratio of RMAP Conformant smelters has been temporarily decreasing. Therefore, we will continue to request tier 1 suppliers to switch to RMAP Conformant smelters. We also expect tier 2 and subsequent suppliers to encourage upstream companies and smelters to switch to RMAP Conformant smelters.

Starting with the fiscal 2021 survey, we requested suppliers to report the scope of their CMRT/EMRT responses not on a company basis (A: Company) but on a part-by-product basis (B: Product) delivered to Ricoh Group. As a result, about 80% of suppliers responded to the questionnaire on a part-by-product basis.

As a result, analyzing the response information from the first-tier suppliers, it was confirmed that there was a possibility that a certain number of products contain parts or materials which originated in the Democratic Republic of the Congo or an adjoining country. Accordingly, the Ricoh Group conducted due diligence on the relevant first-tier suppliers. We will discuss our future business with the suppliers who have not responded to this survey and are judged to require improvement based on the results of the ESG Self-Assessment.

In addition, in fiscal 2020, we began a survey of the cobalt supply chain by identifying major suppliers that had supplied the Ricoh Group with products and parts containing cobalt in the past. The response rate from surveyed suppliers was 92% of the 72 cobalt smelters and refineries and 30RMAP Conformant refineries identified. We also continue to cooperate with industry organizations, such as JEITA and RMI, and we continue to conduct due diligence.

| FY2020 | FY2021 | FY2022 | |||||

|---|---|---|---|---|---|---|---|

| Total | Gold | Tantal | Tin | Tungsten | |||

| Number of smelters & refiners | 300 | 332 | 345 | 175 | 37 | 85 | 48 |

| Number of RMAP conformant smelters & refiners (Conflict-Free) | 228 | 229 | 229 | 95 | 33 | 61 | 32 |

| Number of RMAP Active*5 smelters & refiners | 12 | 18 | 9 | 4 | 1 | 4 | 0 |

| Number of other RMI smelters & refiners*6 | 60 | 85 | 107 | 76 | 3 | 20 | 16 |

| Rate of of RMAP conformant smelters & refiners (Conflict-Free) | 76% | 69% | 66% | 54% | 89% | 72% | 67% |

| Response rate from suppliers | 94% | 95% | 96% | — | — | — | — |

| Cobalt | |||

|---|---|---|---|

| FY2020*7 | FY2021 | FY2022 | |

| Number of smelters & refiners | 35 | 63 | 72 |

| Number of RMAP conformant smelters & refiners (Conflict-Free) | 9 | 30 | 39 |

| Number of RMAP Active smelters & refiners | — | 10 | 5 |

| Number of other RMI smelters & refiners | — | 23 | 28 |

| Rate of of RMAP conformant smelters & refiners (Conflict-Free) | 26% | 48% | 54% |

| Response rate from suppliers | 85% | 95% | 92% |

*5 RMAP Active: Smelters & refineries under RMAP audit or are going to be audited.

*6 other RMI smelters & refiners: RMI certified smelters & refiners other than RMAP Conformant / Active.

*7 Cobalt Survey In fiscal 2020, we conduct a trial survey of a limited number of suppliers.

For information regarding the details of the smelters, seeList of the Smelters or Refinersidentified in Ricoh Group supply chain which were known by RMI

Participation in External Organizations

Ricoh Group is working with the following organizations in an industry-wide effort to resolve the conflict minerals issues.

Supply chain BCM (business continuity management)

The Ricoh Group’s extensive supply chain faces a broad range of external risk factors, such as natural disasters, changes in the international situation, and development of infection. Our customers are particularly aware of this in the wake of the Great East Japan Earthquake. They are demanding, as part of their business requirements, strong risk management capabilities to ensure that their business operations would not be affected even in the event of an emergency. The Ricoh Group's policy is to ensure that customers never have to suspend their work, and we have made our support of social infrastructure operations a high priority. We, therefore, require our suppliers to strengthen their BCM by maintaining redundant production bases and parts procurement channels, and to increase their stocks of materials and components in case of widespread disasters such as those caused by earthquakes, tsunami, floods, fire, accidents or infection including new strains of influenza and COVID-19.

Supplier Hotline

Ricoh has set “Supplier Hotline” which accepts violations to the applicable laws and regulations, Ricoh Group Code of Conduct, and violations of contract with suppliers caused by Ricoh and Ricoh Group’s officers and employees.

(1) The reports we accept on “Supplier Hotline”

The conduct of officers and employees of each Ricoh Group company is governed by laws and regulations, Ricoh Group Code of Conduct.

If you find that officers and employees of the Ricoh Group has (or may have) breached any of the above rules, laws or regulations, or any contract with you as a supplier, please contact Supplier Hotline with the details.

In addition, please refrain from reporting with improper purposes, such as reporting contents that are different from the facts, reporting contents for purposes of slander, intimidation or business.

In FY2022, we appropriately handled reports to the Supplier Hotline.

(2) How to report to Supplier Hotline

Reports to Supplier Hotline are accepted through the report form on this site.(See below)As a general rule, please report under your real name. Anonymous reports are also accepted, but in that case, there is a limit to the confirmation of the facts, etc., and there is a possibility that sufficient investigation may not be conducted.

In addition, please note that we cannot contact you about the results of the response, etc.

(3) Response to the reports

Reports to Supplier Hotline are received and the relevant facts are confirmed by the department not in charge of Ricoh’s normal procurement. We conduct corrective actions promptly when necessary. The whistleblower shall not receive disadvantageous treatment by Ricoh Group merely by submitting the report itself.

(4) Handling of personal information

The personal information collected in this form will not be disclosed to anyone other than to those that have the need to know, to confirm the facts and conduct the investigation, etc. We will only use the information in responding to your requests and for the necessary procedures.

The personal information sent by you will be managed under appropriate security measures and will be managed in strict confidence so that there will be no disadvantage caused to you through the investigations. We will not disclose or provide the information to third parties without your prior consent.

The personal information and requests collected in this form will be used to the extent necessary for confirming the facts and conducting investigation, and will be shared amongst the Ricoh Group related departments for the purpose of responding to your request, confirming facts and conducting investigation, and for improving the quality. Please refer to the “Handling of personal information” about how we handle your personal information.

I agree with the above