- Home

- Sustainability

- Reports on Ricoh's ESG

- Supply Chain Management - Logistics

Supply Chain Management

Logistics

The Ricoh Group is lowering both costs and environmental burden by reducing waste in five areas of the logistics process: packaging, shipping, space, transshipment and storage. Global initiatives include increasing loading efficiency, practicing modal shift and optimizing transportation routes. In addition, we are establishing structures at the product design and development stage to minimize overall costs incurred in logistics through to end-user delivery, parts and packaging materials.

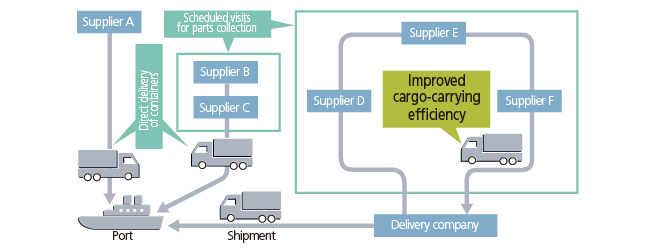

The milk run system

In the milk run system, a single truck collects parts from multiple suppliers after the type and number of parts to be provided by each supplier has been compiled. This raises efficiency by reducing the distance the truck has to travel.

Reducing environmental impact with resource-recirculating eco packaging

The Ricoh Group uses recyclable packaging materials for copiers to reduce the environmental impact.

We have been actively working to reduce the use of packaging materials since 1994, and introduced resin-based “resource-recirculating eco packaging” materials, which can be used repeatedly, for the first time in 2001. The new eco packaging that the Ricoh Group developed in 2017 simultaneously realized a 45% reduction in weight as well as enhanced durability for repeated use compared with conventional materials using structural analysis technology. The Ricoh Group also achieved a compact size by adding a folding structure for when the packaging materials are collected to enable more efficient transportation.

By expanding the use of those packaging materials, the Ricoh Group minimized the amount of materials used and reduced CO2 emissions in its production (estimated amount of reduction in the fiscal year ending March 31, 2018: 91.2 tons/year in the material used; 153.7 tons/year in CO2 emissions).

In recognition of its efforts to devise designs that reduce environmental impact, the Ricoh Group was awarded Large-sized Equipment Packaging Award in the Good Packaging category for the “Japan Packaging Contest 2017” organized by Japan Packaging Institute.

Promoting modal shift

The Ricoh Group is promoting a modal shift from truck to energy-saving modes, including railway and marine transportation. In fiscal 2014, Ricoh Logistics System Co., Ltd. was certified under the Eco-Ship Mark system of Japan's Ministry of Land, Infrastructure, Transport and Tourism, and was recognized by the ministry for being one of the best supporters of its eco-ship modal shift projects.