- Home

- Sustainability

- Reports on Ricoh's ESG

- Supply Chain Management - Production

Supply Chain Management

Production

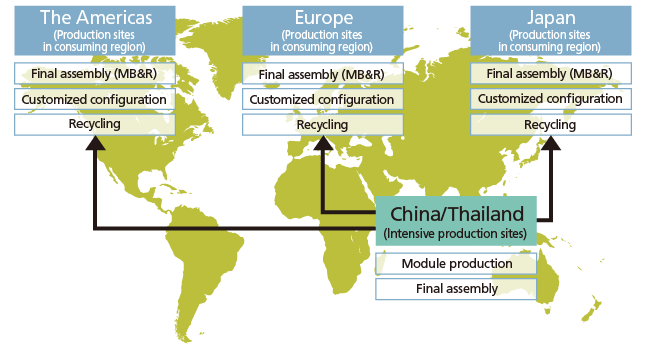

The Ricoh Group aims to have all its products locally produced and locally consumed, as this not only improves production efficiency but also minimizes environmental impact. We are constantly innovating production processes and introducing high-efficiency equipment at all production sites to curb our global CO2 emissions.

Flexible production line

Starting in 1999, Ricoh gradually began eliminating fixed conveyor lines and replacing them with free form production channels that can be dynamically reconfigured to handle changes in production volume and models.

One example is the cart production line, in which multiple carts powered by air cylinders are lined up in a row. The carts move down the line carrying products being assembled. Since conveyors—which consume high amounts of energy - are unnecessary, our unique system significantly reduces environmental impact and energy costs while boosting productivity.

Efficient production closer to the customer

Local production for local consumption allows us to reduce inventories of finished goods and management expenses as well. The production sites are all situated to maximize the efficiency of our MB&R (Modular Build & Replenishment) system, which utilizes manufacturing hubs and configuration centers to optimize quality and productivity while minimizing costs. Being close to the customer, the configuration centers can promptly fulfill orders within their region.

The MB&R production method relies on final assembly at the last possible step of the production process. We make modules at lower cost at intensive manufacturing sites (China and Thailand) and assemble finished products at configuration centers in consuming regions (Japan, the Americas, Europe). This allows us to market model types best suited to regional needs or to respond quickly to changing demands.

MB&R system introduced to filling toner

We use the same on-demand charge system to fill toner for PPCs. In the past, each region needed to keep toner cartridges in stock locally. Though the content of toner is same, there are various volume and PPC types of cartridges. To decrease the stock, we miniaturized the toner filling equipment. It makes compact and low cost filling possible. We have adopted the weekly received and SCM orders placed and postponement concept. Bulks of toner are sent to overseas consumption locations from Japan and the toner is filled locally. According to this system, we control the stock inventories.