- Home

- Sustainability

- Environment

- Achievement of a Zero-Carbon Society

Achievement of a Zero-Carbon Society

Policy/Basic Concept

“Climate change” is one of the most important social challenges which the global community is facing. The adverse effects of climate change are becoming more noticeable in many parts of the world and have become a serious issue influencing not only natural disasters, but also food production and economic security. Companies are expected to step up their efforts to decarbonize their operations in response to climate change.

The Ricoh Group's concept of a sustainable society is expressed in the “Three Ps Balance,” which describes a society that maintains a balance among the three Ps: economy (Prosperity), society (People), and the global environment (Planet).

Based on the Ricoh Group Environmental Declaration, which states “We proactively reduce environmental impact and strive to improve the Earth’s self-recovery capabilities to achieve a zero-carbon society and a circular economy through business.” we have positioned the realization of a decarbonized society as one of our materiality issues in the global environment field. We are engaged in activities to reduce our GHG emissions to achieve the targets for reducing GHG emissions established through back casting, while respecting scientific findings such as those of the IPCC and international agreements like the Paris Agreement.

Specifically, we have set Scope 1, 2, and 3 targets for reducing GHG emissions in 2030,2040 and 2050. We are working together as a group to reduce Scope 1 and 2 GHG emissions through energy-saving activities at our own sites and the use of renewable electricity, and we are going all-out to realize Scope 3 GHG emissions reductions through visualization and reduction activities in the supply chain.

Decarbonization Policy

- Thorough development of energy-saving and fuel conversion.

- Active and effective use of renewable energy.

- Visualization and reduction of GHG emissions in the supply chain.

For details of Ricoh's climate change activities, please refer to the Ricoh Group TCFD Report;

Structures/Systems

To continuously discuss mid- to long-term issues of the Ricoh Group in the areas of environment, society, and governance at the management level, the ESG Committee, chaired by the CEO, was established in May 2018. The committee meets once every quarter with the participation of Senior Management to discuss the status of initiatives, issues, and investment decisions related to ESG themes, such as zero carbonization, as important themes for management. Its deliberations are regularly reported to the Board of Directors, which then supervises the execution of ESG activities at a high level.

In addition, we set a target for reducing GHG emissions as one of the companywide ESG targets established as part of our mid-term management strategy, and at the same time, we set a target for reducing GHG emissions for each business unit, for which we conduct forecast and performance management for each business year. We analyze environmental performance data compiled by our cloud system for our approximately 900 global sites and use this data for PDCA management.

Targets and Performance

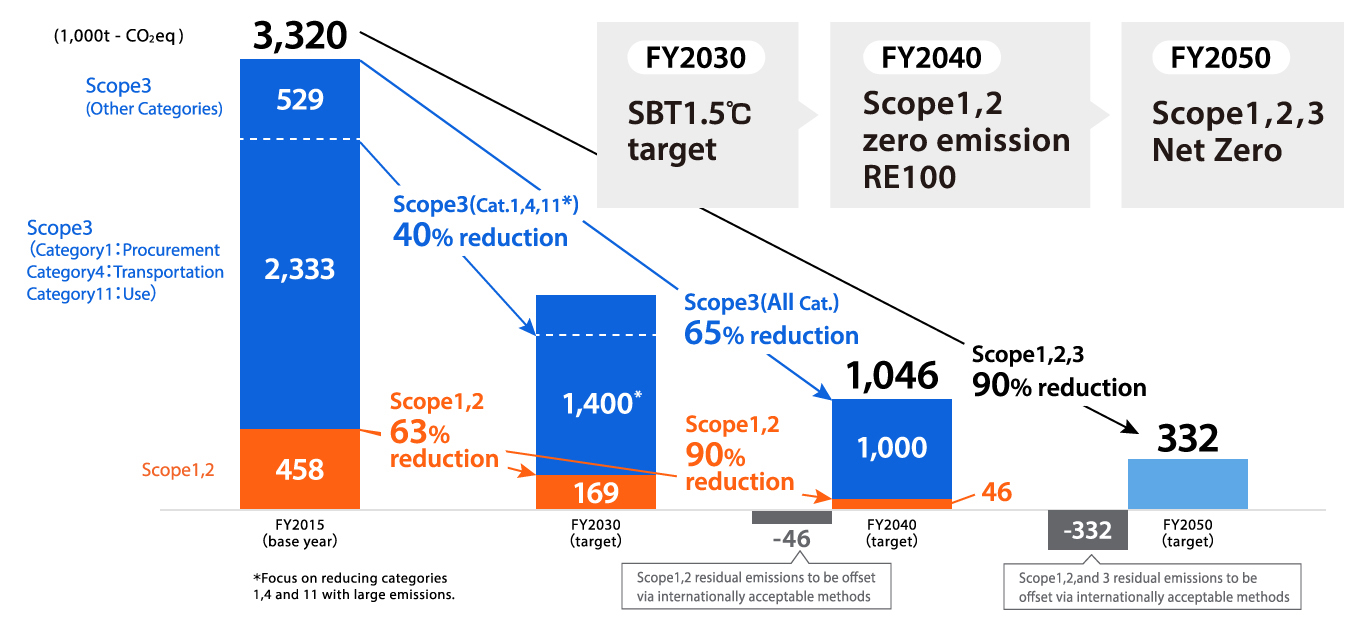

The Ricoh Group aims to achieve net zero GHG emissions by 2050. 2040 goals are net zero GHG emissions in Scope 1 and 2, and a 100% renewable energy ratio for the electricity used in our business activities. Moreover we have obtained SBT 1.5°C certification for our 2030 target, which is consistent with the level required to limit the rise in global temperature to less than 1.5°C in Scope 1, 2, and 3.

Ricoh Group environment goals (zero-carbon)

Goals for 2050

- GHG Scope 1*1, 2*2, 3*3 : Net zero GHG emissions

Goals for 2040

- GHG Scope1,2 : Zero emission (90% reduction compared to 2015 level, residual emissions are offset via internationally acceptable methods)

- GHG Scope3 : (65% reduction compared to 2015 level, all categories)

- Renewable energy usage ratio: 100%

Goals for 2030

- GHG Scope1 and 2: 63% reduction (compared to 2015 level)

- GHG Scope3 : 40% reduction (compared to 2015 level, procurement/ transportation/use categories)

- Renewable energy usage ratio: 50%

*1 GHG Scope 1: All direct GHG emissions from our manufacturing plants, offices, vehicles, etc.

*2 GHG Scope 2: Indirect GHG emissions from the consumption of electricity and heat that we purchase

*3 GHG Scope 3:Emissions in the supply chain from business activities (procurement, transportation and use categories)

GHG Scope 1 and 2 reduction

Active and effective use of renewable energy

- Purchase of renewable energy

- In-house renewable energy power generation

- Introduction of PPA contracts

- Strategic utilization of renewable energy certificates

Energy saving and fuel conversion

- Innovation of production and business processes

- Installation of highly efficient and energy saving equipment

- Electrification of production process and fuel conversion

- Promotion of Net Zero Energy Buildings

- Operational innovation of corporate fleet vehicles and electrification

GHG Scope 3 reduction

Decarbonization in the supply chain

- Zero-emission material procurement

- Development of energy-saving equipment, introduction of renewable energy by customers

- Use of non-fossil fuel-based transportation

- Use of non-fossil fuel-based services

| Performance |

GHG Scope 1,2

GHG Scope 3

Electric power

|

|---|

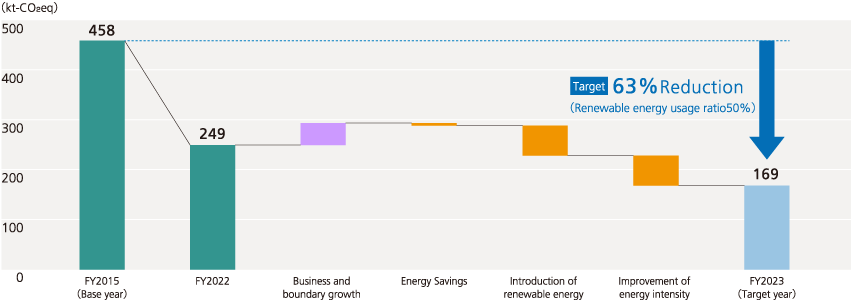

Road Map for Zero-Carbon Society to Achieve 2030 Targets

2030 Scope 1, 2: Initiatives and plans to achieve 63% reduction

Active use of renewable energy

We will promote purchasing renewable electricity certificates and introducing on-site PPAs, and aim to complete the transformation to RE100 by 2030 in overseas countries. In Japan, we will work with companies willing to lobby the government to reduce the cost of renewable electricity and expand procurement methods, and will strive to accelerate the introduction of renewable energy.

Promoting energy saving activities

We will promote improvement of manufacturing processes, introduce high-efficiency and energy-saving equipment, and electrify facilities at our production sites. At non-production sites, in Japan, we will expand the number of ZEB office buildings, and at overseas sites, we will promote the office relocation to energy-efficient offices. As for company vehicles, we will work to ensure that all company vehicles are driven in an environmentally friendly manner, and we will promote the conversion to Electric Vehicles (EVs), Fuel Cell Vehicles, and other energy-saving vehicles. We will also work in the area of Scope 1 issues where electrification is difficult, such as the use of steam from boilers, and will make effective use of waste heat loss from heat pumps, etc., and strive to introduce future technologies, such as hydrogen.

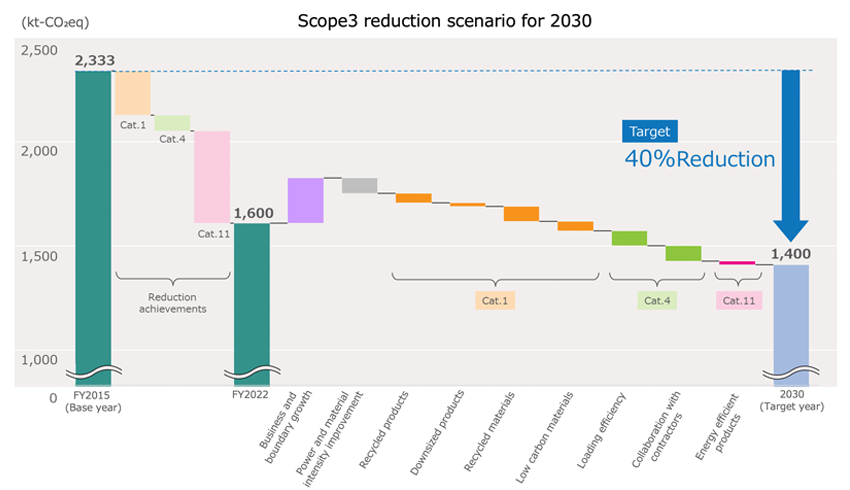

2030 Scope 3: Initiatives and Plans for 40% Reduction

We will work together with the entire value chain, including suppliers, customers, and transportation contractors, to achieve a Scope 3 reduction.

Avoided emissions

The Ricoh Group calculates the GHG emissions (Scope 1, 2 and 3) from its own business activities and sets environmental targets to reduce these emissions. On the other hand, GHG emissions increase with business growth and entry into new businesses. However, for example, society's GHG emissions can be reduced by improving the energy-saving performance of newly developed MFPs, reducing their power consumption and replacing older models, and the digital printing presses that Ricoh is aiming to expand sales of meet the market needs for high-mix, low-volume lots, and can save resources and energy by reducing inventory compared to conventional offset printing presses, resulting in a reduced environmental impact on society as a whole. Thus, the greenhouse gases reduced in society by Ricoh's products and solutions are referred to as "Avoided Emissions".

Target:1,400 kt (End of FY2025)

Performance:

|

|

|

FY2019 |

FY2020 |

FY2021 |

FY2022 |

|---|---|---|---|---|---|

|

Provision of energy saving products |

Amount (CO2 equivalent) reduced through the introduction of models to customers' sites with enhanced energy-saving functions for MFPs, printers and other equipment as well as lighting and air-conditioning control systems. |

212 | 244 | 197 | 226 |

|

Provision of digital services |

Amount (CO2 equivalent) reduced through the introduction of energy efficient solutions/services to customers' sites, including conversion from offset printing to digital printing and duplex and with suppliers. |

155 | 124 | 762 | 752 |

|

Resource saving of products |

Amount (CO2 equivalent) reduced associated with procurement of raw materials and parts by lowering the input of new resources as a result of promoting reuse of recovered equipment, use of recycled materials, production of more compact, lightweight models, and use of ecological |

67 | 64 | 74 | 67 |

|

Total (1,000t-CO2eq) |

434 | 431 | 1,033 | 1,045 | |

For other achievements related to realizing a Zero-Carbon Society, please see below.

ESG data.

Initiatives

Initiatives for Scope 1 and 2 emissions reduction

【Active and effective use of renewable energy】

- Signing of VPPA and strengthening of adoption of renewable energy, with focus on supplementary potential

- Promote implementation of on-site PPA model at production sites

- Implementation of 100% renewable energy at A3 Multifunction Printer production sites worldwide

- Introduction of Comprehensive Evaluation System for Renewable Electricity

- Expansion of renewable energies usage at sites

【Thorough development of energy saving and fuel conversion】

- Installation of Waste Heat Recovery Heat Pumps at Production Sites

- Establishment of global standard for promoting sustainable real estate

- Expansion of ZEB Office Buildings and Application to Business Proposals for Customers

- Expansion of Environment-friendly buildings

Initiatives for Scope 3 emissions reduction

- Strengthening of activities to promote the use of life cycle assessments (LCAs)

- Reduction measures in marine transport

- Products contributing to society’s decarbonization

- Energy saving and energy creation businesses (Japanese)

Contributing to achievement of a zero-carbon society

Contributing to achievement of a zero-carbon society