- Home

- Technology

- Ricoh's Technology

- Stereo Camera

Stereo Camera

Ricoh has developed high-speed, high-precision stereo cameras that can respond to varied industry needs. To do so, Ricoh combined its own calibration technology with parallax computation technology.

Ricoh stereo camera features

A stereo camera detects depth information of a subject using the parallax of two cameras aligned left and right.

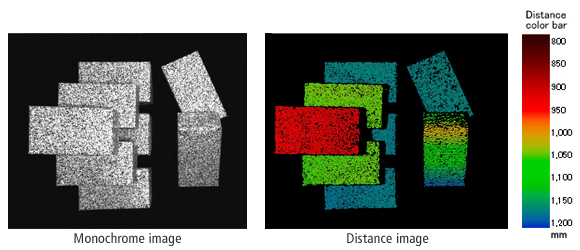

Varying distance to the subject is expressed as different colors

Figure 1: Example output image

To accomplish high accuracy of the depth information acquired by the stereo camera, optical distortion of the two cameras and misalignment of the two cameras caused by mechanical assembling or the like must be corrected; beyond that, the two cameras must be positioned in parallel. Ricoh has succeeded in producing stereo cameras that are highly precise. Precision was made possible by synergistically integrating several technologies accumulated at Ricoh: optical technology that precisely evaluates optical characteristics, image processing technology that corrects the optical characteristics accurately, and packaging technology that enables high-precision assembly; the result is a proprietary calibration system. Image processing and parallax computation processing are optimally installed on a chip inside the stereo camera. This makes it possible to output accurate three-dimensional information fast and in real time.

Industrial stereo camera

As the demand for safety and automation in industrial fields such as logistics, construction, and civil engineering accelerates, it is increasingly necessary to detect the surrounding environment with cameras and other sensors. Ricoh stereo cameras contribute to solving customers’ problems, providing a versatile three-dimensional vision that ensures accuracy and speed and can be assembled as a system.

Figure 2: Industrial stereo camera

Applications

Usage scenario 1: Stereo camera for forklift

At worksites where forklifts are used with people and objects nearby, stereo cameras three-dimensionally capture and distinguish people and objects from the surrounding obstacles with high accuracy. This prevents accidents involving collisions between the forklift and the people or objects.

Wide-angle technology enables detection over a 130° field of view horizontally. Recognition technology based on 3D imaging allows the detection of unspecified persons without the need to carry tags, unlike conventional methods that require workers to carry tags for detection. Mounting the image processing and power supply functions inside the camera enables a single compact package that is easy to install and operate, allowing the package to be installed on existing forklifts operating at a site.

Figure 3: Image of stereo camera package installed on a forklift

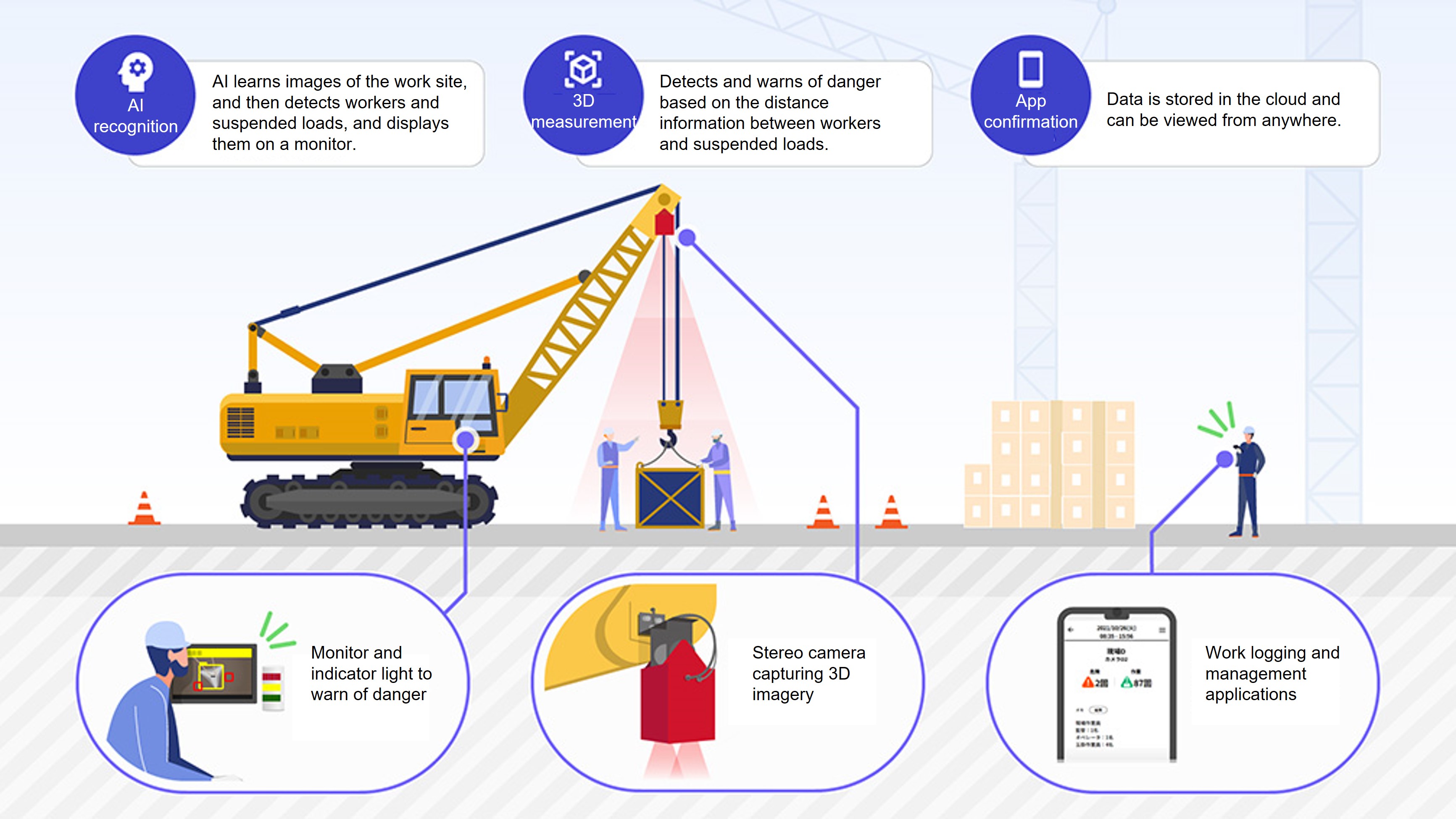

Usage scenario 2: Crane operation safety support system

Digital technology supports safety checks at sites where cranes are operated. Until now, guidance staff have mainly handled such checks visually. By utilizing AI recognition technology in addition to this stereo camera technology, suspended loads and workers can be automatically detected, and their positions measured in three dimensions. This system detects the risk of collision based on the measurement results and notifies the crane operator to prevent collision accidents. This system is expected to be used in the construction, civil engineering, and manufacturing industries and in various other workplaces where worksite safety is an issue.

Figure 4: Image of crane operation safety support system

Sorted by : field “Machine Vision” | product type “FA Cameras”