Shareholder Meeting Virtual Tour

Take a virtual tour of our 119th Ordinary General Meeting of Shareholders venue.

You can click or scroll on the image below to view the site from any angle.

This tour uses Ricoh’s THETA360.biz virtual tour solution.

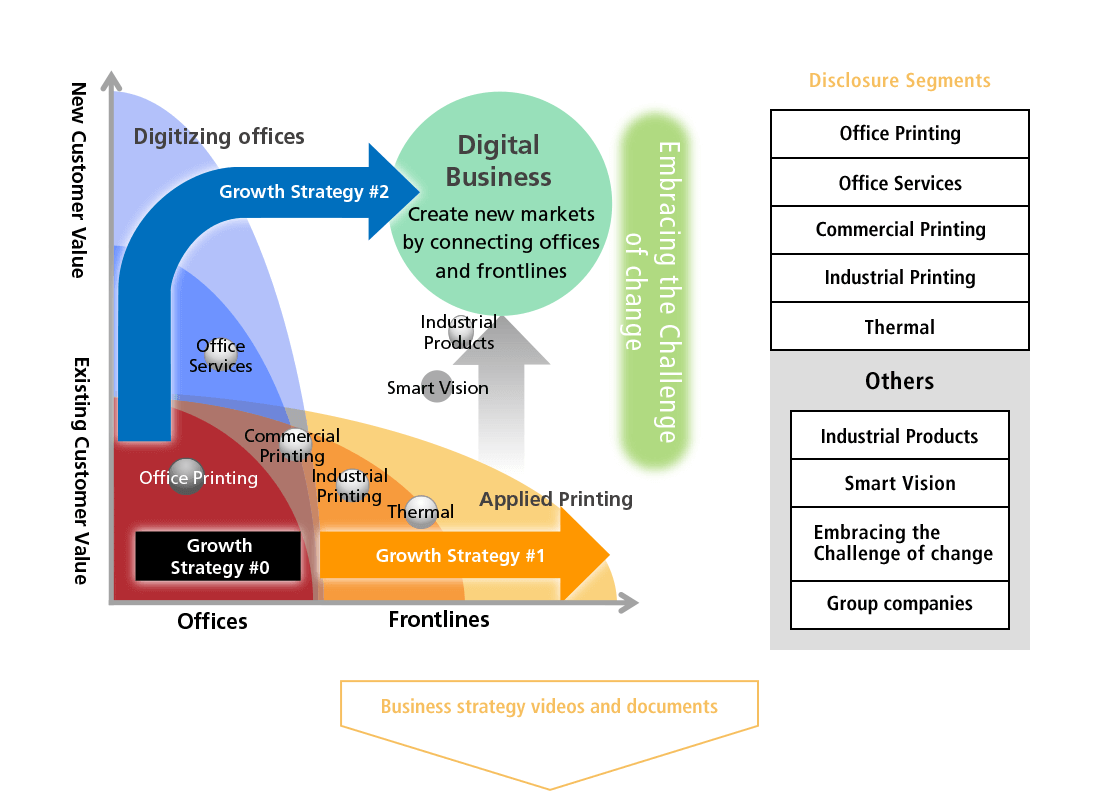

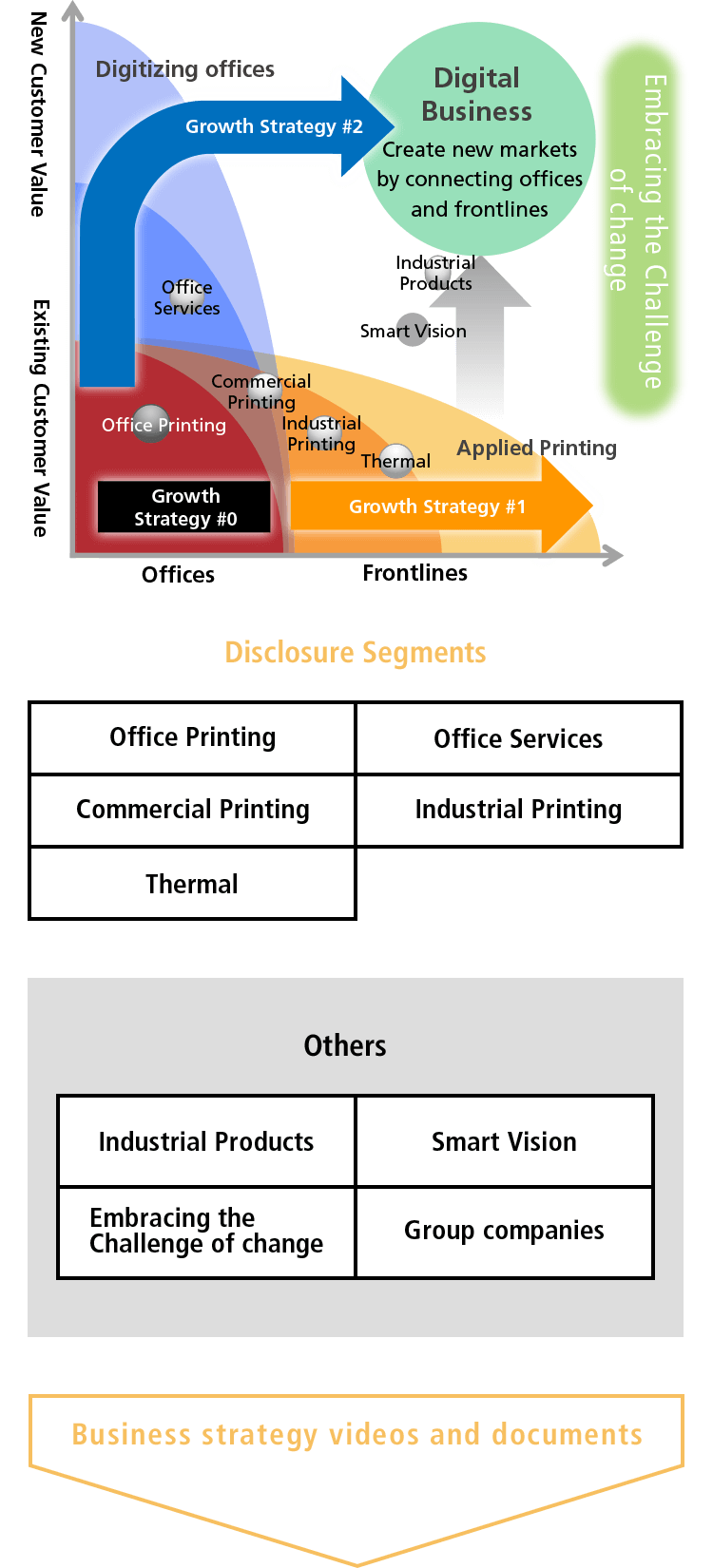

RICOH Ignite Growth Strategy and each business

We rolled out the RICOH Ignite growth strategy covering through March 31, 2023. Expansion efforts encompassed increasing profitability in the core Office Printing field while developing new businesses that could become key to Ricoh’s future.

Noteworthy Products and Services

Featured Topics

Innovating eco-friendly processes that enhance the safety and reliability of food, clothing, and housing

Offering media products and systems that print barcodes and other variable information to identify items for retailing, etc.

Providing modules and devices that leverage miniaturization, precision machining, and digital technologies

Businesses are becoming more efficient and offering more flexible working hours and locations. Ricoh swiftly identifies changing business needs and continually adds features to its multifunction printers (MFPs). While lowering MFP downtimes, we have collaborated with external cloud services so people can build more efficient, smarter work spaces. We also provide timely information and advanced security.

The deterioration of bridges and other structures necessitates hazardous work at heights to assess safety maintenance. The work is expensive, and there are too few inspectors. Ricoh launched a pilot project in which camera-equipped drones and advanced technology remotely examine decks and supports of bridges, slashing inspection times. Our solution helps resolve personnel and budget issues while safeguarding lives.

Roads are central to social infrastructure and constantly deteriorate. Conventional road surface assessment vehicles are expensive and often cannot enter residential roads. Ricoh thus developed a road surface monitoring system that can be installed on ordinary vehicles to examine all sorts of road surface. We have substantially decreased workloads by automating entire inspection workflows, from recording road surfaces to providing results.

Language and other barriers make corporate meetings challenging. Ricoh’s intelligent whiteboards enhance communication by using artificial intelligence to translate presentations in real time. The whiteboards can also take minutes automatically and distribute them to remote participants. These devices accelerate decision-making through on-the-spot feedback.

Perhaps we should think more about the water we consume, as the world may soon face shortages. Ricoh is tackling this challenge by drawing on its digital technologies to develop printers that can dye fabrics without using water, preventing pollution.

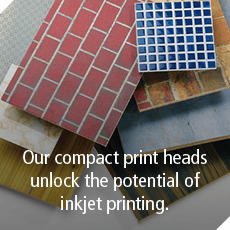

Ricoh printing technology works on all sorts of construction materials, from tiles to panels and frames. People can print designs on all sorts of media, including wood, glass, ceramic, metal, and plastic. Ricoh’s proprietary print heads make this happen. The internal heaters are compatible with an array of highly adhesive UV inks for many materials. Our inkjet technology will keep evolving to cater to even more applications in the years ahead.

Ricoh technology improves efficiency at hospitals and clinics by making it possible to instantly locate patients, staff, and equipment. Staff shortages have increased medical professionals work loads. One problem is waste time tracking down equipment. Ricoh’s indoor location information service provides real-time locations of patients, staff, and equipment. It is also to seek specific individuals and groups, bolstering operational efficiency. Other key benefits are shorter patient wait times, faster examinations, and better nurse efficiency.

Ricoh thermal paper is used for labels on packages of precooked side dishes, boxed lunches, and other foods. The labels present information on everything from item names, prices, and net weights to production and expiration dates and barcodes. Our technology excels at reproducing two-dimensional barcodes, for superior readability. For shipping labels, users can easily read barcodes to verify package information. Our thermal paper resists heat and water, making it perfect in logistics. The paper employs removable adhesive so users can take labels off without damaging boxes.

The numerous problems from changing box labels include increased workloads from replacements, wasted labor costs, unsightly residue from previous label adhesives, and system issues from information remaining after incomplete label removal. Ricoh eliminates these issues because it uses a semiconductor laser to create contactless labels that can be overwritten 1,000 times or so. The labels remain impervious to ultraviolet light for five years. They can be used outdoors for logistics purposes and benefit the environment by reducing waste.

R&D into automated driving and advanced driving support systems is accelerating. The need to process massive amounts of data in real time has traditionally hampered automated driving safety. But Ricoh leaped forward with high-speed data processing innovations that enabled it to pioneer the mass production of automotive stereo cameras. Our devices combine three-dimensional image processing and proprietary dense stereo matching technologies to detect pedestrians, other vehicles, guard rails, and road conditions. The technology controls steering to avoid obstacles.

Ricoh’s 360-degree image capturing technology has led to exciting new applications that bring spaces to life in healthcare, education, and real estate. Allowing people to view locations virtually from any angle is the next best thing to physically being there. We built a compact camera that makes it easy for anyone to take 360-degree images.

Ricoh is helping caregivers through technology. Simply attaching our proprietary sensors under the bed legs enhances patient protection. The sensors detect where individuals are on beds and the positions they are in. Data from the sensors can determine whether or not people are awake. The sensors measure body rhythms through breathing and other parameters. They can also measure body weight. Our bed sensors will continue to evolve so they can even detect the pulses of sleeping individuals.

Ricoh is continuing to revolutionize 3D printer modeling technology. Depending on the materials, some 3D-printed objects are strong enough for real applications. Such items are starting to reach markets. Ricoh is drawing on years of print technology innovation to revolutionize 3D printing. We will keep identifying user needs to develop and sell technologies that broaden the potential and practicality of 3D printers.